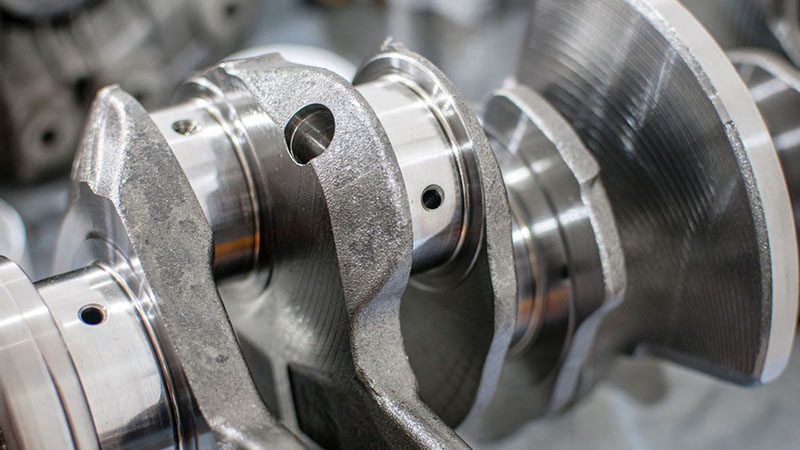

Crankshafts are the backbone of engine performance, converting piston movement into the rotational force that powers vehicles.

For B2B buyers, auto parts distributors, and engine builders, choosing the right crankshaft manufacturer is about more than cost—it’s about quality, reliability, and long-term supply assurance.

In this guide, we highlight ten of the world’s leading crankshaft manufacturers, focusing on their capabilities, product offerings, and why they stand out in a competitive global market.

Overview

| Position | Manufacturer | Country | Specialty | Notable Clients / Strengths |

|---|---|---|---|---|

| 1 | MAHLE GmbH | Germany | Forged crankshafts, engine parts | OEM supplier to BMW, Ford, Mercedes; strong R&D |

| 2 | Thyssenkrupp AG | Germany | Forged/machined crankshafts | Supplies VW, Toyota; vertical integration, high-volume output |

| 3 | Cummins Inc. | USA | Diesel crankshafts, complete engines | Heavy-duty focus; commercial vehicles and marine engines |

| 4 | SCAT Enterprises | USA | Performance billet/forged crankshafts | Custom racing applications; strong presence in aftermarket |

| 5 | Bryant Racing Inc. | USA | Custom billet crankshafts | Supplier to NASCAR, NHRA; known for motorsport excellence |

| 6 | Hitachi Astemo Ltd. | Japan | Precision drivetrain components | Supplies Honda, Nissan, Subaru; advanced manufacturing capabilities |

| 7 | Musashi Seimitsu Industry Co., Ltd. | Japan | Precision-forged crankshafts | Supplies Honda, Toyota, and other Japanese automakers |

| 8 | Bharat Forge Ltd. | India | Commercial vehicle and OEM crankshafts | One of the largest forging companies; strong global footprint |

| 9 | Teksid S.p.A. (Stellantis Group) | Italy | Cast iron crankshafts | OEM supplier to Fiat, Chrysler, Peugeot; cost-effective casting |

| 10 | Nanjing Woda Auto Technology Co., Ltd. | China | Forged crankshafts, engine parts | Exported to 100+ countries; factory-direct pricing and service |

Top 10 Crankshaft Manufacturers in the World

1. MAHLE GmbH

Headquarters: Germany

Why They Stand Out: MAHLE is a global leader in engine components with a strong focus on innovation, sustainability, and precision manufacturing. The company is a long-term OEM supplier to renowned brands such as BMW, Mercedes-Benz, and Ford.

Their forged crankshafts are engineered for high thermal and mechanical loads, often integrated into advanced powertrains including turbocharged and hybrid engines. MAHLE operates R&D and production facilities in over 30 countries.

2. Thyssenkrupp AG

Headquarters: Germany

Why They Stand Out: Thyssenkrupp is one of the world’s largest suppliers of forged automotive components. The company manages every stage of the crankshaft production process—from steelmaking to final machining—ensuring complete quality control.

Thyssenkrupp’s crankshafts are used in light vehicles, commercial trucks, and industrial engines, and are trusted by global OEMs including Volkswagen, Stellantis, and Toyota.

3. Cummins Inc.

Headquarters: USA

Why They Stand Out: Cummins is known for building some of the most durable diesel engines in the world, particularly for commercial applications.

Their crankshafts are specifically engineered for high-load endurance, making them ideal for use in heavy-duty trucks, buses, construction machinery, and marine engines. Cummins also applies advanced simulation and testing to improve fatigue resistance and fuel efficiency.

4. SCAT Enterprises

Headquarters: USA

Why They Stand Out: SCAT is a household name in the performance aftermarket. The company produces billet and forged crankshafts tailored for high-horsepower and racing engines, including those used in drag racing, hot rods, and Pro Touring builds.

Their products are renowned for tight tolerances, balance optimization, and material strength. SCAT also offers custom crankshaft solutions for unique engine configurations.

5. Bryant Racing Inc.

Headquarters: USA

Why They Stand Out: Bryant Racing is synonymous with custom, high-performance billet crankshafts. Their components power engines in NASCAR, NHRA, and endurance racing events.

Every crankshaft is CNC-machined from premium-grade steel and undergoes rigorous balancing and testing. Bryant is known for its close collaboration with racing engineers to optimize performance under extreme stress.

6. Hitachi Astemo Ltd.

Headquarters: Japan

Why They Stand Out: Formed from the merger of Hitachi Automotive Systems and several Honda-affiliated companies, Hitachi Astemo is a leading global Tier 1 supplier.

They offer crankshafts, camshafts, and drivetrain components to major Japanese and international automakers. With a strong focus on innovation, automation, and material science, the company plays a key role in next-generation powertrain development.

7. Musashi Seimitsu Industry Co., Ltd.

Headquarters: Japan

Why They Stand Out: Musashi is a Tier-1 supplier specializing in drivetrain and engine components, including high-precision forged crankshafts. With facilities across Asia, North America, and Europe, Musashi provides components to major automakers such as Honda, Toyota, and Nissan.

Their crankshafts are produced using advanced warm-forging and 3D simulation techniques for maximum strength and weight optimization.

8. Bharat Forge Ltd.

Headquarters: India

Why They Stand Out: Bharat Forge is one of the largest forging companies globally and a key supplier of crankshafts to Daimler, Volvo, Cummins, and other international brands.

Their product portfolio spans commercial vehicle, passenger car, and industrial engine applications. Bharat Forge is known for vertical integration, strong R&D, and flexible manufacturing capabilities that support both OEMs and aftermarket clients.

9. Teksid S.p.A. (Stellantis Group)

Headquarters: Italy

Why They Stand Out: Teksid brings decades of experience in cast iron metallurgy to the crankshaft industry. As part of the Stellantis Group, the company produces high-quality cast crankshafts for Fiat, Chrysler, and Peugeot.

Their products are especially valued in mid-range gasoline and diesel engines for their cost-effectiveness and structural integrity.

10. Nanjing Woda Auto Technology Co., Ltd.

Headquarters: China

Why They Stand Out: Nanjing Woda has positioned itself as a dependable global partner in forged crankshaft manufacturing. The company supplies both OEM and aftermarket customers in over 100 countries.

Their product line includes crankshafts for gasoline and diesel engines, as well as cylinder heads and complete engine assemblies. With ISO certification and a focus on global export logistics, Woda offers scalable solutions and responsive customer service.

Crankshaft Selection Tips for B2B Buyers

When evaluating crankshafts, keep the following in mind to ensure long-term performance, cost-effectiveness, and seamless integration into your supply chain:

1. Material Type

- Forged Steel: Offers the highest strength and fatigue resistance, making it ideal for commercial vehicles, performance engines, and high-load industrial applications. Forged crankshafts are heat-treated and often feature rolled fillets to extend service life.

- Cast Iron: A more budget-friendly option suited for lower horsepower or economy vehicles. While not as strong as forged or billet, modern casting techniques can still deliver consistent quality for light-duty use.

- Billet Steel: CNC-machined from a solid bar, billet crankshafts are extremely durable and customizable. They are typically reserved for motorsports and high-performance applications where tolerances, balance, and strength are critical.

2. Key Specifications

- Stroke and Journal Size: These directly affect the engine’s displacement, power characteristics, and compatibility. Ensuring exact measurements is essential for proper engine function.

- Weight and Balance: Crankshaft mass influences engine response and fuel efficiency. Balanced crankshafts reduce vibration, increase longevity, and support smoother operation.

- Hardness and Surface Finish: Look for nitrided or induction-hardened surfaces with fine finishes to minimize wear on bearings and reduce friction under stress.

- Engine Compatibility: Ensure the crankshaft matches your engine family and fits all OEM design parameters. Incompatibility can lead to premature wear or failure.

3. Supplier Considerations

- Standards Compliance: Check for ISO 9001, IATF 16949, or OEM-specific certifications to ensure consistent quality.

- Production Capacity and Lead Time: Choose a supplier who can meet your volume needs and has reliable logistics for on-time delivery, especially if you’re operating on tight manufacturing schedules.

- Customization and Documentation: Look for partners who can offer private labeling, custom packaging, and detailed product traceability including metallurgy reports, balance data, and inspection certifications.

- After-Sales Support: Strong technical support and warranty services are crucial, especially if you’re sourcing internationally. Ensure the supplier is responsive and experienced in handling export logistics and compliance.

Careful evaluation of these factors can help you select a crankshaft that not only meets your technical requirements but also enhances your operational efficiency and product reputation.

Why Choose Nanjing Woda as Your Crankshaft Partner

Nanjing Woda Auto Technology Co., Ltd. is a global supplier of high-performance engine components, with a strong specialization in forged crankshafts for both gasoline and diesel applications.

Backed by over a decade of manufacturing experience, we serve hundreds of clients across Latin America, Southeast Asia, Africa, the Middle East, and Eastern Europe.

Our crankshafts are engineered to meet or exceed OEM performance standards, ensuring long service life, precise fitment, and consistent performance across diverse engine platforms. Whether you’re an engine rebuilder, parts distributor, or OEM buyer, Woda provides reliable supply solutions tailored to your business.

What Sets Us Apart

1. ISO-Certified Manufacturing Facilities

We operate under strict quality control systems compliant with ISO 9001 and IATF 16949 standards. Every crankshaft undergoes precision machining, surface hardening, dynamic balancing, and rigorous quality checks before shipment.

2. Competitive, Factory-Direct Pricing

As a direct manufacturer, we control every stage from forging to packaging. This allows us to offer stable, competitive pricing without sacrificing quality, making us an ideal long-term partner for global buyers.

3. Export-Ready Logistics & Global Reach

With a professional export team and strong freight partnerships, we ship to over 100 countries with reliable lead times. All products are securely packed for container, pallet, or air freight depending on your volume and urgency.

4. Flexible OEM & ODM Services

We support custom crankshaft development based on your drawings or specifications. We also offer ODM branding, allowing you to build your own aftermarket brand with laser markings, custom packaging, and technical documentation.

5. Low MOQ, High Scalability

Whether you’re a startup importer or a large-scale distributor, our minimum order quantity starts at just 5 units. This helps you reduce inventory pressure while maintaining access to high-quality components.

Conclusion

Crankshafts are fundamental to engine performance—and choosing the right manufacturing partner can make all the difference when it comes to quality, reliability, and long-term supply success.

From global powerhouses like MAHLE and Thyssenkrupp to precision leaders such as Musashi Seimitsu and Bharat Forge, the companies featured in this list represent the best in the industry, trusted by top automakers and large-scale OEMs around the world.

However, if you’re looking for more flexibility, competitive pricing, and personalized service, Nanjing Woda Auto Technology offers a smart and scalable alternative. With low MOQs, fast global shipping, and OEM-quality forged crankshafts, we’re an ideal choice for aftermarket distributors, regional importers, and fast-growing engine parts businesses.

We’re here to support your growth—with reliable products, responsive service, and a commitment to long-term partnership.

Let’s build something strong together.

Contact our team for a custom quote →