At the heart of every internal combustion engine lies a critical component that serves as the foundational structure for the entire powerplant. The engine cylinder block represents one of the most essential and robust components in modern automotive engineering, providing the structural backbone that enables efficient operation across countless applications from passenger cars to heavy duty engines.

Understanding the engine cylinder block is crucial for anyone working with engines, whether you’re a professional mechanic, engineering student, or automotive enthusiast. This comprehensive guide explores every aspect of cylinder blocks, from their basic functions to advanced manufacturing processes and maintenance requirements.

What is an Engine Cylinder Block

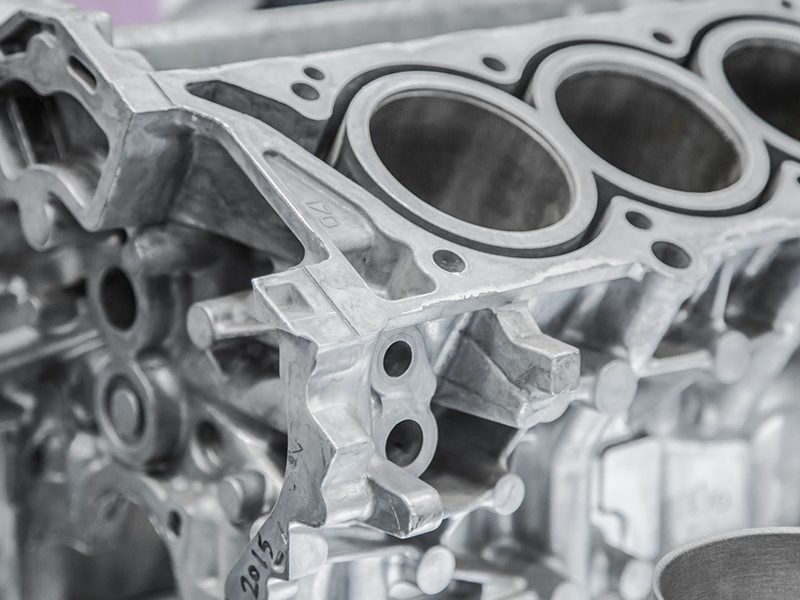

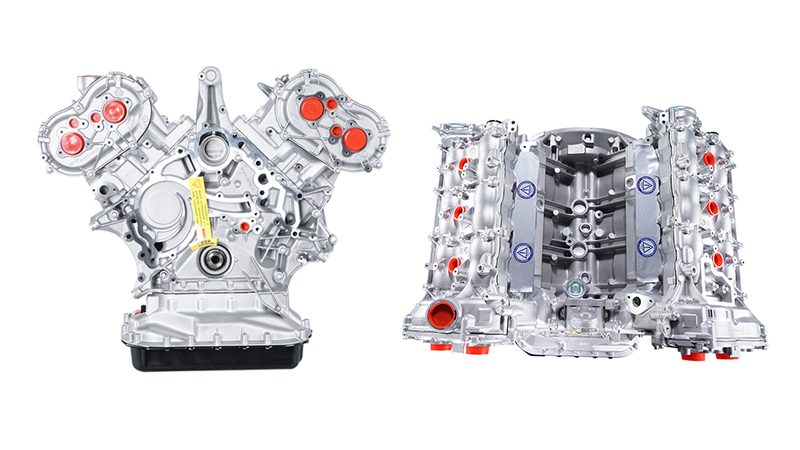

The engine cylinder block, also known as the engine block, serves as the primary structural foundation of internal combustion engines. This foundational structure houses the engine’s cylinders where the combustion process takes place and pistons move up and down to generate power. The block forms the main structure that supports and aligns all major components of the engine, including the crankshaft, camshaft, and connecting rods.

Modern engines rely on cylinder blocks made primarily from cast iron or aluminum alloy to withstand the extreme temperatures and pressures generated during the combustion processes. The block must endure intense mechanical forces while maintaining precise dimensional stability to ensure proper alignment of all the cylinders and critical components.

Beyond its structural role, the cylinder block integrates essential systems for engine lubrication, cooling, and power transmission. It contains intricate networks of oil passages and coolant passages that regulate temperature and provide lubrication to prevent significant damage from heat and friction.

Key Components of the Cylinder Block

The cylinder block incorporates several integral elements that work together to support the engine’s operation. Understanding these key components helps explain how cylinder block work within the broader engine system.

Cylinder Bores and Combustion Chambers

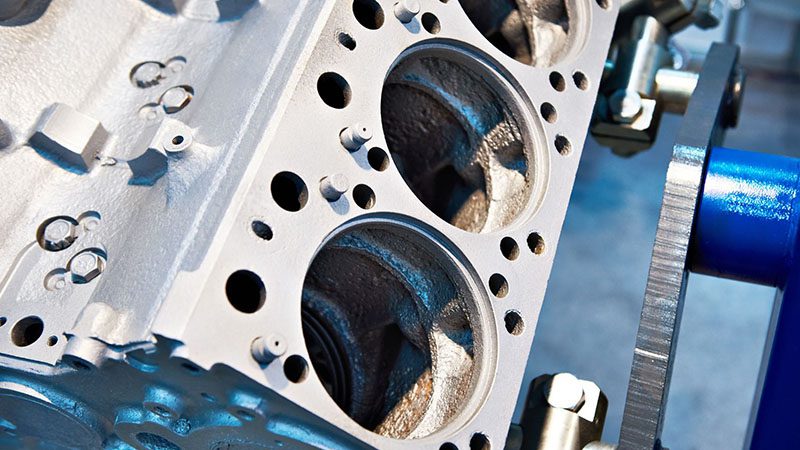

The cylinder housing represents the most visible feature of any engine block. These precisely machined openings house the pistons and form the lower boundary of the combustion chambers where the air-fuel mixture is compressed and ignited. The cylinder walls must maintain exact dimensions to ensure proper piston fit and compression ratio while withstanding the intense pressures generated during combustion.

In line engine configurations feature all cylinders arranged in a single row, while V-type blocks position cylinders in two angled banks. Regardless of configuration, each cylinder bore requires exact machining tolerances to prevent excessive wear and maintain optimal engine performance.

Crankshaft Support System

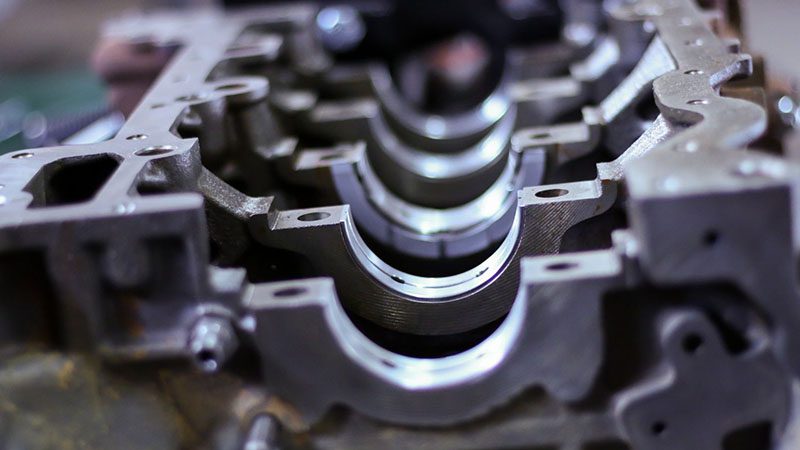

The lower section of the cylinder block contains the crankcase and main bearings that support the crankshaft. These main structure elements include bearing caps and journals that secure the crankshaft while allowing smooth rotation. The connecting rods attach to the crankshaft within this protected crankcase environment, transferring power from the reciprocating pistons to rotational motion.

Coolant and Lubrication Networks

Water jacket passages surround each cylinder to circulate engine coolant and prevent overheating. These coolant passages connect to the water pump and radiator system, forming a complete thermal management network. Similarly, oil galleries distribute engine oil under pressure throughout the block, ensuring proper lubrication reaches all moving components.

The integration of these separate components within the block eliminates the need for external plumbing while protecting vital fluid circuits from contamination and damage.

Primary Functions of the Engine Cylinder Block

The cylinder block serves multiple critical functions that enable reliable engine operation across diverse applications and operating conditions.

Structural Integrity and Component Alignment

The block provides structural integrity for the entire engine assembly, maintaining precise alignment of all major components during operation. This rigid foundation prevents flexing and distortion that could damage gaskets, bearings, or other precision components. The mounting surfaces for the cylinder head, oil pan, and various engine components require exact machining to ensure leak-free operation.

Combustion Chamber Formation

Working with the cylinder head, the block forms complete combustion chambers where the combustion process takes place. The head gasket seals the junction between block and cylinder heads, creating a pressure-tight environment for controlled combustion. This sealed chamber must withstand extreme pressures while maintaining proper compression ratios for efficient fuel burning.

Power Transfer and Support

The block supports the crankshaft assembly that converts reciprocating piston motion into rotational power. The flywheel mounts to the crankshaft within the block’s bell housing, transferring power to the transmission system. This power transfer occurs through precisely aligned bearing surfaces that must maintain their geometry throughout the engine’s service life.

Integrated System Support

Modern cylinder blocks integrate mounting points and passages for numerous engine systems. The valve train components, fuel injectors, spark plugs, and exhaust ports all interface with the block either directly or through the cylinder head assembly. This integration reduces complexity while ensuring proper alignment and sealing between separate components.

Types of Cylinder Block Configurations

Engine manufacturers utilize various cylinder block configurations to optimize performance, packaging, and cost effectiveness for different applications.

Inline Cylinder Blocks

Inline configurations arrange all the cylinders in a single straight row, creating a straightforward design that offers excellent accessibility for maintenance and cost effective manufacturing. These blocks work well for smaller displacement engines and provide easy access to components like spark plug replacement and valve adjustments.

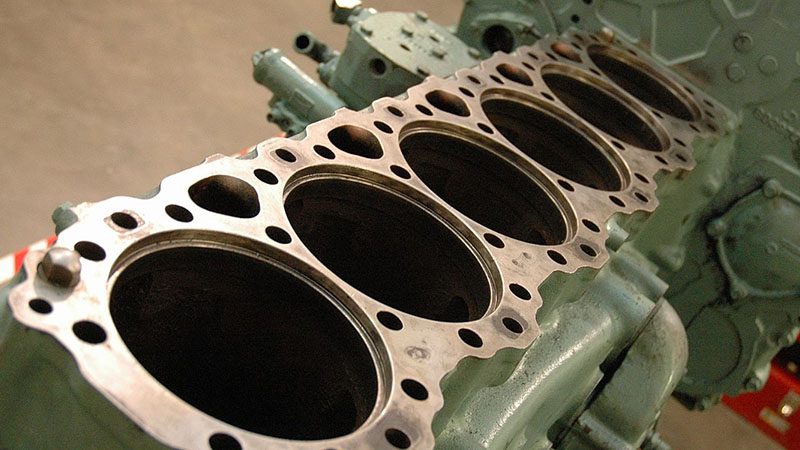

Four-cylinder and six-cylinder inline engines represent the most common applications, particularly in passenger cars where simplicity and fuel efficiency take priority over maximum power output.

V-Type Cylinder Blocks

V-type cylinder blocks feature two banks of cylinders arranged at an angle, usually 60 or 90 degrees. This configuration allows more cylinders in a shorter overall length, making the engine more compact while enabling higher power output. V6 and V8 engines dominate performance and truck applications where power density and packaging constraints drive design decisions.

The V-configuration requires more complex manufacturing and maintenance procedures but offers superior balance and smoother operation compared to equivalent inline designs.

Boxer and Radial Configurations

Boxer cylinder blocks position cylinders horizontally in opposed banks, creating a low center of gravity that improves vehicle handling. This configuration appears primarily in specialized applications like sports cars and aircraft engines where balance and packaging advantages outweigh increased complexity.

Radial cylinder blocks, used mainly in aircraft applications, arrange multiple cylinders around a central crankshaft. This design provides excellent cooling and power-to-weight ratios but requires specialized manufacturing techniques.

Cylinder Block Materials and Manufacturing

The choice of materials and manufacturing processes significantly impacts engine performance, durability, and cost across different applications.

Cast Iron Cylinder Blocks

Cast iron blocks offer superior strength, durability, and vibration dampening properties that make them ideal for heavy duty engines and commercial applications. The material’s excellent wear resistance allows direct piston contact with cylinder walls without requiring separate cylinder sleeves.

Cast iron’s thermal properties provide good heat retention, which benefits diesel engines that require high compression temperatures for proper fuel ignition. The material also offers excellent machinability and repair characteristics, making it practical for long-service applications.

Aluminum Alloy Cylinder Blocks

Aluminium alloy blocks provide significant weight reduction compared to cast iron, typically reducing overall engine mass by 40-50%. This weight savings improves fuel efficiency and vehicle handling while offering superior thermal conductivity for better heat dissipation.

Most modern engines in passenger cars utilize aluminum blocks with steel cylinder sleeves or special coating treatments to provide adequate wear resistance. The aluminum construction requires more sophisticated manufacturing processes but enables the lightweight designs demanded by contemporary efficiency standards.

Manufacturing Processes

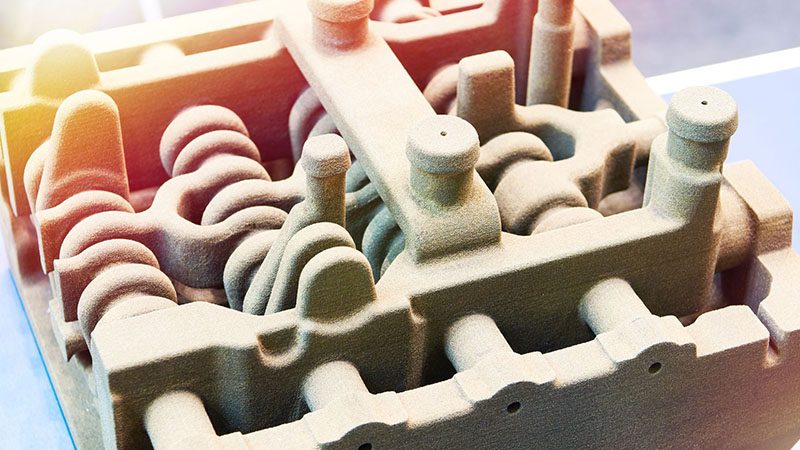

Cylinder block production begins with casting in specialized foundries using either sand casting or die casting techniques depending on material and volume requirements. The casting process creates the basic block structure including cylinder bores, coolant passages, and oil galleries.

Following casting, extensive machining operations create the precise surfaces required for proper engine function. CNC machining centers perform cylinder boring, deck surfacing, and bearing bore machining to achieve the tight tolerances essential for reliable operation.

Quality control procedures include dimensional inspection, pressure testing of coolant and oil circuits, and surface finish verification to ensure each block meets specification requirements.

Cylinder Block Relationship with Other Engine Components

The cylinder block interfaces with virtually every major engine component, requiring precise engineering to ensure proper function and sealing.

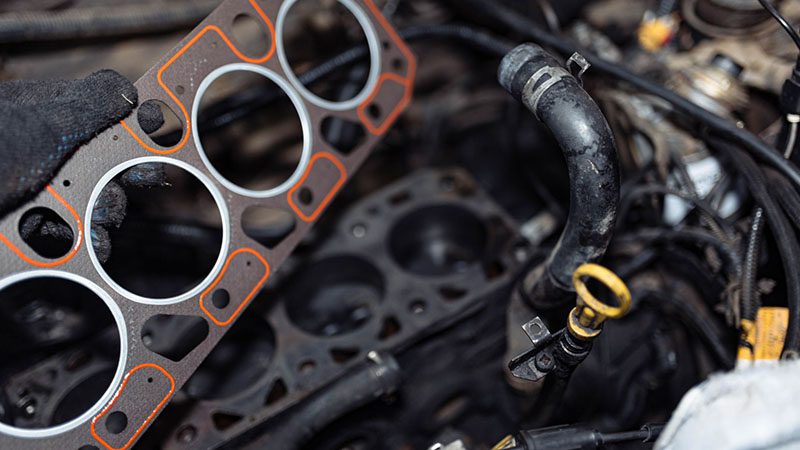

Cylinder Head Integration

The cylinder head bolts to the block’s deck surface, forming the upper portion of each combustion chamber. The head gasket creates a seal between these components while accommodating thermal expansion differences between materials. The cylinder head contains the valve train, spark plugs, and often the camshafts that control air intake and exhaust gas flow.

This critical interface must maintain perfect sealing under extreme pressure and temperature variations while allowing for different thermal expansion rates between the aluminum head and cast iron block in many engines.

Oil Pan and Lubrication System

The oil pan attaches to the bottom of the block, forming the engine’s oil reservoir. The oil galleries within the block distribute pressurized oil from the pump to main bearings, connecting rod bearings, and other lubricated components. The oil filler cap provides access for oil changes while maintaining system pressure.

Transmission Connection

The block’s bell housing provides mounting points for the transmission and houses the flywheel assembly. This connection must transfer engine torque while maintaining precise alignment between the crankshaft and transmission input shaft.

Common Cylinder Block Problems and Solutions

Understanding common problems helps identify issues early and implement appropriate solutions before significant damage occurs.

Cylinder Bore Wear

Over time, friction between pistons and cylinder walls creates wear that reduces compression and allows oil consumption. Light wear responds to honing procedures that restore proper surface finish, while severe wear requires reboring to accept oversized pistons or installation of cylinder sleeves.

Regular oil changes and proper warm-up procedures minimize bore wear by maintaining adequate lubrication and preventing thermal shock to the cylinder walls.

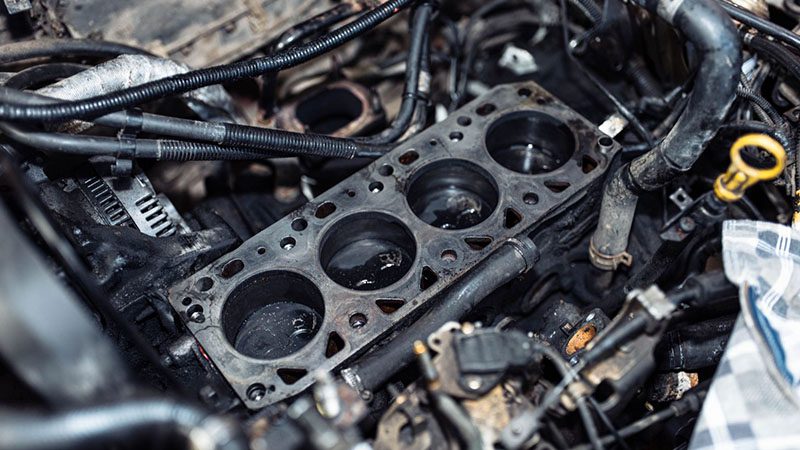

Cracking and Structural Damage

Cylinder block cracks typically result from overheating, coolant freezing, or excessive mechanical stress. Small cracks in non-critical areas may be repairable through welding or specialized crack repair processes, but major structural cracks usually require block replacement.

Proper coolant maintenance and avoiding severe overheating prevents most cracking problems. Regular inspection during routine maintenance helps identify developing issues before they become catastrophic failures.

Coolant System Corrosion

Corrosion within coolant passages restricts flow and reduces cooling efficiency, potentially leading to overheating and engine damage. Regular coolant replacement using proper antifreeze mixtures prevents corrosion while maintaining optimal heat transfer properties.

Professional cleaning procedures can remove moderate corrosion deposits, but severe cases may require passage repair or block replacement depending on the extent of damage.

Cylinder Block Maintenance and Inspection

Proper maintenance extends cylinder block service life and prevents common problems that lead to expensive repairs.

Routine Maintenance Procedures

Regular engine oil changes prevent sludge accumulation in oil galleries and maintain proper lubrication of all moving components. The oil filter should be replaced with each oil change to ensure clean lubricant circulation throughout the engine.

Coolant system maintenance includes periodic coolant replacement, thermostat inspection, and pressure testing to verify system integrity. The water pump and related components should be inspected for leaks or wear during routine service intervals.

Inspection Techniques

Visual inspection during oil changes can reveal external leaks, crack development, or unusual wear patterns. Internal inspection requires specialized equipment including borescopes for cylinder examination and pressure testing equipment for coolant system verification.

Professional diagnostic procedures may include magnetic particle inspection or dye penetrant testing to reveal hairline cracks not visible during routine inspection. These advanced techniques help identify developing problems before they cause engine failure.

Preventive Measures

Maintaining proper operating temperatures prevents thermal stress that can crack cylinder blocks or warp sealing surfaces. Avoiding rapid temperature changes during warm-up and cool-down cycles reduces thermal shock to engine components.

Using proper fuel grades and maintaining clean air filtration prevents combustion contamination that can accelerate cylinder bore wear and damage other engine components.

Applications Across Different Industries

Engine cylinder blocks serve diverse applications beyond automotive use, each requiring specific design characteristics and material properties.

Automotive Applications

Passenger cars utilize lightweight aluminum blocks optimized for fuel efficiency and emissions compliance. These engines balance performance requirements with durability expectations for typical consumer driving patterns.

Commercial trucks and buses employ robust cast iron blocks designed for continuous high-load operation and extended service intervals. These applications prioritize durability and repairability over weight savings.

Industrial and Marine Applications

Industrial generators and stationary engines use heavily reinforced blocks designed for continuous operation under constant loads. These applications require maximum durability and serviceability for critical power generation duties.

Marine engines incorporate corrosion-resistant materials and specialized cooling systems to handle the harsh saltwater environment. The blocks must withstand continuous operation while providing reliable power for vessel propulsion.

Specialized Performance Applications

Racing engines utilize exotic materials and specialized manufacturing techniques to achieve maximum power output while minimizing weight. These blocks often incorporate features like dry cylinder sleeves, integrated cooling circuits, and reinforced bearing structures to handle extreme operating conditions.

Aircraft engines require lightweight construction with exceptional reliability standards. The cylinder blocks must operate efficiently across wide altitude and temperature ranges while meeting strict weight limitations.

Conclusion

To wrap up, the engine cylinder block is the core component that powers everything from vehicles to industrial machinery. Its role in converting mechanical power efficiently is crucial for reliable engine performance.

Understanding its design, materials, and maintenance needs ensures long-term engine reliability. Whether in cars or industrial engines, proper care and timely maintenance are key to avoiding costly failures.

At Nanjing Woda Auto Technology Co., Ltd., we specialize in providing high-quality engine parts, including premium cylinder blocks and related components, for a variety of applications.

With over 25 years of experience in the automotive industry, we are committed to offering durable solutions that meet the needs of both commercial and individual customers. Whether you need reliable parts for maintenance, replacement, or upgrades, we are here to help you maintain the highest standards of engine performance.

Contact us now for expert advice or to browse our extensive catalog of engine parts.