Modern engines look simple from the outside, but inside the factory, thousands of precise steps and countless engineering standards work together to create a reliable power unit. For distributors, workshops, and importers, understanding how engines are actually made helps you evaluate manufacturers better, avoid low-quality suppliers, and make smarter sourcing decisions.

In this guide, we’ll walk through the entire engine manufacturing process—from the first design sketches to the final round of quality control—based on how real-world engine manufacturers operate today.

1. Design & Engineering: Where Every Engine Begins

Before a single bolt is installed, manufacturers spend months—sometimes years—developing the engine’s structure, performance goals, and durability requirements. These early engineering decisions directly influence cost, performance, emissions, and long-term reliability.

Understanding the Requirements

Manufacturers start by defining what the engine needs to achieve:

- Power and torque output

- Emissions standards

- Fuel efficiency

- Expected lifespan

- Budget and parts availability

- Vehicle applications

For example, commercial diesel engines focus heavily on torque and longevity, while small gasoline engines prioritize weight and efficiency.

CAD Modeling & Digital Simulation

Engineers use 3D CAD software to design each component down to fractions of a millimeter. Advanced simulation tools test:

- Heat distribution

- Vibration behavior

- Combustion efficiency

- Structural stress at high RPM

These digital tests allow manufacturers to catch weaknesses long before building a prototype.

Prototype Testing

Next, a prototype is built and tested on a bench. Engineers measure:

- Compression pressure

- Oil pressure stability

- Fuel consumption

- Knock resistance

- Vibration levels

Only after multiple rounds of refinement will the engine move to the manufacturing stage.

2. Raw Materials, Casting & Forging: Building the Foundation

A good engine depends heavily on the quality of its materials. This stage defines how strong, durable, and heat-resistant the engine will be.

Casting the Cylinder Block

Most blocks are made from cast iron or aluminum. Cast iron blocks excel in durability and heat tolerance, while aluminum blocks offer weight savings and better cooling efficiency. Manufacturers pour molten metal into sand molds shaped for coolant passages, bearing saddles, and cylinder walls. The block cools, solidifies, and undergoes:

- Dimensional inspection

- Hardness testing

- Crack detection

| Material | Strength | Heat Tolerance | Weight | Common Use |

|---|---|---|---|---|

| Cast Iron | Very high | Excellent | Heavy | Diesel & heavy-duty engines |

| Aluminum | Moderate | Good | Light | Small gasoline engines |

Forging the Crankshaft & Connecting Rods

High-stress components like crankshafts and rods are usually forged, not cast, because forging aligns the metal structure, increasing strength. After forging:

- The crankshaft goes through rough machining

- Oil passages are drilled

- Counterweights are shaped

Quality Control on Materials

Manufacturers typically check:

- Chemical composition of the metal

- Microstructure integrity

- Surface hardness

- Dimensional precision

This prevents defects that could lead to premature failure.

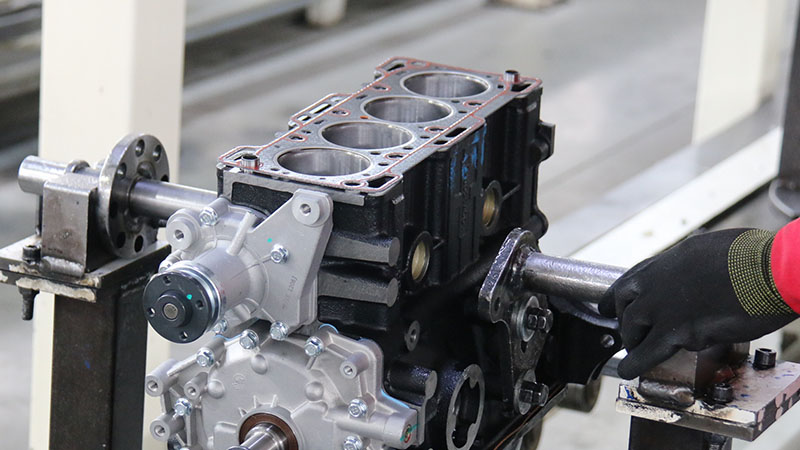

3. Precision Machining: Turning Rough Metal Into Engine Parts

After casting and forging, all major components go through detailed machining.

Cylinder Block Machining

Processes include:

- Boring the cylinders

- Honing to achieve the perfect crosshatch pattern

- Deck machining for a flat sealing surface

- Thread tapping for bolts and accessories

Proper machining ensures correct compression, optimal oil film control, and long-term durability.

Cylinder Head Machining

Manufacturers perform:

- Valve seat cutting

- Port shaping

- Surface leveling

- Guide installation

The accuracy of these steps affects airflow, combustion efficiency, and valve sealing.

Crankshaft Grinding & Balancing

Precision is essential here. Each crank journal is ground to specified tolerances, then dynamically balanced to reduce vibration and bearing wear.

Pistons, Camshafts, and Other Parts

Small components go through milling, drilling, polishing, or nitriding depending on the design.

Cleanliness is also critical—manufacturers follow strict cleanliness standards to prevent debris from ruining the engine.

4. Engine Assembly Line: Bringing the Engine to Life

Once individual parts are prepared, the engine assembly process begins. This is usually done in several major stages.

Sub-Assembly Preparation

Before technicians start building the engine itself, they create multiple pre-assembled units. These “sub-assemblies” make the final assembly more organized and reduce the risk of mistakes.

Piston + Ring Sets

Pistons are matched with the correct piston rings based on cylinder measurements. Technicians check ring end-gaps, install the rings in the correct orientation, and verify that each piston matches its cylinder bore grade. This ensures proper sealing and oil control.

Valve Assemblies

For cylinder heads, valve-related components are pre-assembled. This includes inserting valve stems, installing springs, fitting retainers, and verifying valve movement. Any stiffness or misalignment would cause later sealing issues, so the head receives a full movement and leak check.

Oil Pumps

Oil pump rotors or gears are lubricated and installed with precision. Clearances are checked to prevent oil starvation or excessive pressure once the engine is running.

Timing Components

Timing chains, tensioners, guides, and belt pulleys are pre-checked and assembled into partial kits. This ensures all timing parts are correct for the engine version and reduces the chance of mismatch.

Every sub-assembly is inspected before moving to the next area. Each workstation has its own QC checklist to prevent errors from accumulating later.

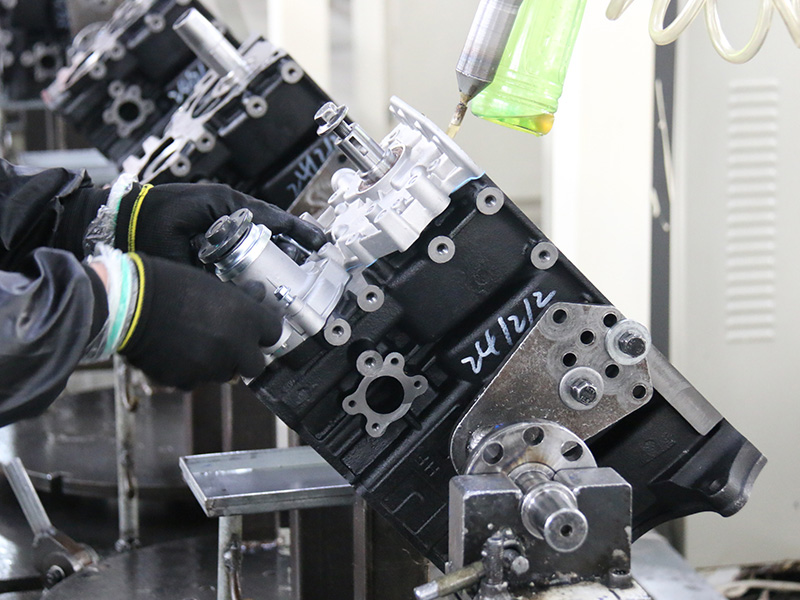

Lower-End Assembly (Short Block)

The lower end of the engine—often called the short block—is the foundation of the entire unit. This is where the rotating assembly (crankshaft, pistons, and connecting rods) is installed.

Installing the Crankshaft and Bearings

Technicians lay the main bearings in place, lubricate them with assembly oil, and position the crankshaft into the block. They then install the main caps and tighten them using manufacturer-specific torque-and-angle sequences. This ensures the crankshaft spins freely without excessive clearance or friction.

Fitting Pistons & Connecting Rods

Pistons are carefully inserted into the cylinder using a ring compressor. The connecting rod caps are installed onto the crank journals with precise torque settings. After installation, technicians manually rotate the crankshaft to verify that each piston moves smoothly without binding.

Checking Side Clearances & End Play

Using feeler gauges or dial indicators, technicians confirm:

- Rod side clearance

- Crankshaft end play

- Bearing lubrication coverage

These measurements are crucial for longevity and noise reduction.

Applying Correct Torque Values

Every bolt—from bearing caps to rod bolts—requires a specific torque tolerance. Many factories use electronic torque wrenches linked to the QC system, ensuring every value is recorded and traceable.

In modern facilities, many of these tools are part of torque-controlled, digitally monitored assembly systems that automatically verify each tightening step for accuracy and consistency.

At this stage, the short block is now a functional rotating assembly that serves as the engine’s bottom end.

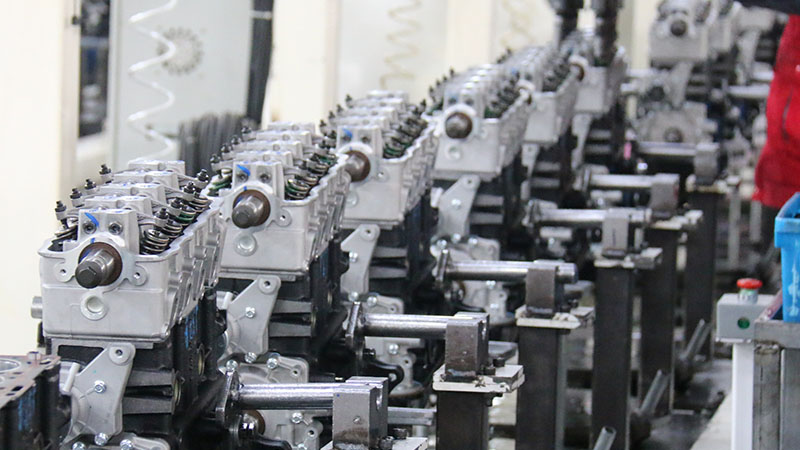

Upper-End Assembly (Cylinder Head)

Once the lower end is complete, the focus shifts to the cylinder head—the heart of airflow and combustion.

Assembling Valves, Springs, and Camshafts

Technicians install intake and exhaust valves, followed by springs, retainers, and lifters/tappets. Each valve is checked for:

- Smooth travel

- Proper seating

- Correct spring tension

Camshafts are installed next, ensuring alignment marks and timing references are perfectly matched.

Head Gasket Placement

A correctly matched head gasket is positioned over the block. This gasket must align precisely, as it seals coolant, combustion, and oil passages between the block and head.

Installing the Cylinder Head on the Block

The head is carefully lowered onto the block using a guide fixture. Head bolts or studs are tightened in a strict sequence, usually in multiple stages:

- Initial torque

- Angle tightening

- Final torque adjustment

This prevents warping and ensures a perfect seal under combustion pressure.

After this, the engine contains both its lower and upper mechanical core.

Final Assembly (Long Block / Complete Engine)

The last stage of the assembly line brings all components together into a ready-to-test power unit.

Timing System Installation

Manufacturers install either:

- A timing chain with guides and tensioners, or

- A timing belt with pulleys and covers

Camshaft and crankshaft timing marks must line up perfectly—any deviation will cause rough idle, low compression, or even engine damage.

Installing Oil Pump, Water Pump & Accessories

The lubrication and cooling systems are completed:

- Oil pump is secured and primed with assembly oil

- Water pump is installed

- Thermostat housing is fitted

- Oil filter adapter, sensors, and gaskets are added

Front & Rear Covers, Seals, and Gaskets

Technicians install:

- Crankshaft seals

- Timing covers

- Valve covers

- Rear main seal housings

All sealing surfaces are cleaned and torqued to prevent leaks.

Manifolds, Sensors, and Auxiliary Components

Depending on the engine version, the assembly may include:

- Intake & exhaust manifolds

- Fuel rails and injectors (if applicable)

- Knock sensors, cam position sensors, crank sensors

- Engine brackets and mounting points

At this point, the engine has its full structure, appearance, and core systems installed. It finally resembles the complete unit that will soon undergo testing.

5. Engine Dyno Testing & Performance Verification

No reputable engine manufacturer ships an engine without testing it first. Even with perfect machining and assembly, real-world behavior can only be confirmed through controlled performance tests. This is where cold testing and hot dyno testing play a crucial role.

Cold Testing (No Ignition, No Fuel)

Cold testing happens before the engine is ever started. An electric motor rotates the crankshaft while sensors monitor key mechanical values. It helps detect issues early without exposing the engine to heat or combustion.

During cold testing, manufacturers check:

Crank Rotation Resistance

Ensures the crankshaft turns smoothly. Abnormal resistance may indicate tight bearings, piston binding, or misalignment.

Oil Pressure Build-Up

Confirms the pump can build pressure quickly and consistently. Low pressure may point to gasket issues or internal blockage.

Compression Balance

Sensors measure whether each cylinder has consistent compression. Irregular readings usually mean valve sealing or piston ring issues.

Leak Testing

Air or vacuum tests verify the sealing of coolant passages, oil galleries, and combustion chambers.

Cold testing is a quick, non-destructive way to catch major mechanical faults before the engine runs.

Hot Testing (Dyno Test)

After passing the cold test, the engine moves to a hot test bench, where it is started, fueled, and operated under controlled loads. This verifies real-world performance.

During hot testing, manufacturers check:

Power & Torque Output

The dyno measures whether the engine meets its designed power and torque values across the RPM range.

Idle Stability

Technicians look for smooth, consistent idle without misfires, vibration, or fuel trim issues.

Temperature Control

Coolant temperature, thermostat response, and overall heat behavior are monitored to ensure proper cooling performance.

Vibration & Noise

Sensitive sensors detect knocking, ticking, timing noise, or bearing rumble—any unusual sound is investigated.

Fuel Efficiency & Combustion Quality

Dynos track the air–fuel ratio, fuel consumption, and basic emissions signatures.

Leak & Smoke Observation

Technicians check for any oil leaks, coolant leaks, or abnormal exhaust smoke during operation.

| Test Type | What It Measures | Purpose | Benefits |

|---|---|---|---|

| Cold Test | Compression, oil pressure, rotation resistance | Detect mechanical issues before combustion | Non-destructive, fast |

| Hot Test (Dyno) | Power, torque, temperature, emissions | Verify real-world performance | Ensures engine readiness |

Endurance Testing (Optional)

Some manufacturers also run extended reliability tests—continuous running, load cycles, and hot–cold cycles—to simulate real-world wear and validate long-term durability.

Why This Matters

Proper dyno testing confirms that every engine performs as expected before it leaves the factory. For B2B buyers, this dramatically reduces failure rates, warranty risks, and unexpected returns—making it one of the most important steps in modern engine manufacturing.

6. Final Quality Control & Export Preparation

After passing performance tests, the engine enters its last checkpoint: final quality control. Here, technicians verify dimensions, appearance, labeling, and export readiness to ensure every unit shipped meets consistent factory standards.

Precision Measurements

QC teams use CMM machines and precision tools to confirm that key dimensions fall within specification. Common checks include:

Deck Height

Confirms a flat, correct-height surface for proper compression and head gasket sealing.

Bearing Clearances

Ensures smooth crankshaft rotation and long-term durability.

Valve Timing Accuracy

Verifies camshaft alignment, timing marks, and chain/belt positioning.

Surface Finish & Tolerances

Checks flatness, roughness, and alignment of machined surfaces such as the block deck, head face, and crank journals.

These measurements help guarantee consistent quality across each production batch.

Final Inspection

After dimensional checks, the engine goes through a practical, hands-on inspection.

Visual Checks

Looking for scratches, casting defects, sealant overflow, and overall cleanliness.

Noise & Rotation Check

Technicians manually rotate the assembly to confirm there are no unusual clicks, rubbing, or resistance.

Accessory Verification

Ensures sensors, pumps, covers, manifolds, and brackets match the customer’s configuration.

Serial Number Assignment

A unique ID is applied and recorded for traceability and future support.

Packaging & Shipping

Once approved, the engine moves to export preparation.

Corrosion Protection

Surfaces are coated with anti-rust oil to prevent oxidation during transport.

Protective Wrapping

Plastic film or moisture-proof materials shield the engine from dust and humidity.

Reinforced Wooden Crates

The engine is bolted or strapped to the crate base and packed in a strong, export-grade wooden box.

Extra Shock & Moisture Protection for Sea Freight

Foam padding, corner guards, and desiccant bags are added to ensure safe arrival after long-distance shipping.

7. What Separates a Good Engine Manufacturer From a Poor One?

Not all engine manufacturers follow the same standards. The best ones invest in proper engineering, materials, and testing, while low-tier suppliers often cut corners. Here are the key traits that set reputable manufacturers apart:

High-Quality, Properly Sourced Materials

Good manufacturers use certified alloy grades and reliable casting/forging sources. Poor suppliers often use inconsistent or low-grade materials that wear out quickly.

Precise Machining Capabilities

Reputable factories rely on modern CNC equipment and control tight tolerances across every surface and clearance. Lower-tier shops typically use outdated machines that produce uneven bores, poor sealing surfaces, or loose bearing fits.

Complete, Consistent QC Documentation

Every engine comes with measurement records, test results, and batch information. Poor manufacturers either skip QC entirely or provide incomplete paperwork.

Proper Dyno Testing

Good manufacturers run each engine through cold and hot testing to confirm power output, oil pressure, temperature behavior, and smooth operation. Cheaper suppliers often skip testing, leading to unpredictable results.

Experience With Global Export Standards

Reliable manufacturers understand packing requirements, export paperwork, shipping protection, and why engines need anti-rust treatment for long routes. Poor suppliers frequently overlook these basics.

Transparent Communication & Technical Support

Top manufacturers provide clear updates, installation guidance, and fast after-sales support. Lower-tier suppliers are often slow to respond or disappear after delivery.

These factors directly influence engine reliability and how well the product performs in real-world use—making the choice of manufacturer a critical decision for any distributor or workshop.

8. Why B2B Buyers Prefer Working Directly With Manufacturers

Working directly with an engine manufacturer offers clear benefits for importers, workshops, and distributors, including:

- Better pricing and a more stable supply chain

- Direct access to matching spare parts

- Reliable after-sales and technical support

- Consistent quality across batches

- Ability to request specific configurations

- Reduced risk of counterfeit or mixed-sourcing components

This is especially important when sourcing high-demand engines often needed in global markets.

Conclusion

Engine manufacturing is a detailed process that combines engineering, precision machining, and rigorous testing. Understanding how an engine is built makes it easier to evaluate suppliers, avoid low-quality manufacturers, and choose a reliable partner for your business.

About Us

At Nanjing Woda Auto Technology Co., Ltd., we specialize in complete engines, cylinder heads, crankshafts, camshafts, and key engine components for B2B buyers worldwide. With more than 25 years of manufacturing and export experience, we support distributors, workshops, and importers with:

- Consistent OEM-grade quality

- Reasonable MOQ for wholesale orders

- Full QC documentation for every engine

- Professional packaging and sea-shipping support

If you’re looking for a dependable engine manufacturer, our team is ready to help.

Ready to Source Engines or Engine Parts?

Contact us to request a quote, ask for a product catalog, or speak directly with our sales team. We support global shipping and provide complete solutions for B2B buyers.