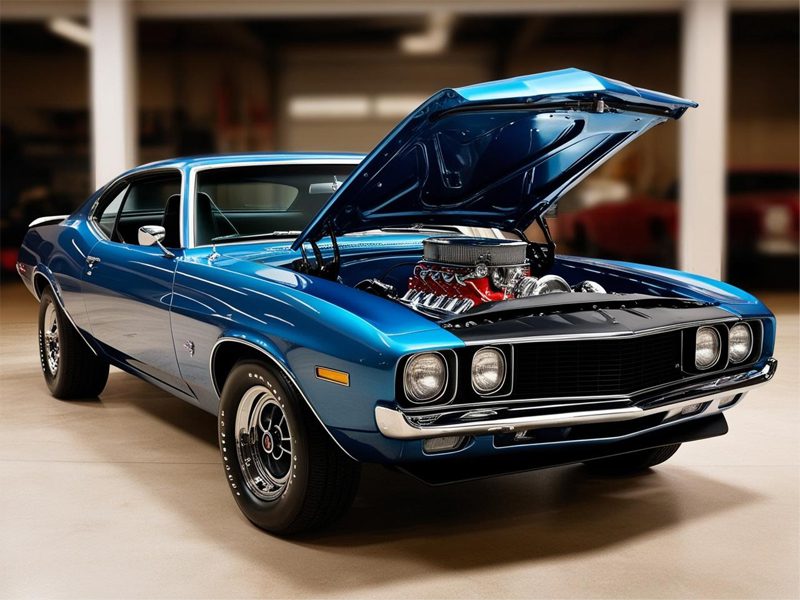

Have you ever wondered what powers your car, getting it to roar to life and glide smoothly down the road?

At the heart of every vehicle lies a masterpiece of engineering: the engine. Often called the “heart of the car,” this intricate machine transforms fuel into energy with precision and power.

But what really goes on under the hood? What are the key parts that make it all happen?

In this article, we’ll take a closer look at the essential parts of a car engine, exploring their roles and how they work together to drive your vehicle.

Whether you’re a car enthusiast, a curious driver, or just looking to understand your vehicle better, this guide has got you covered.

Let’s lift the hood and dive into the fascinating world of car engines!

What is a Car Engine?

An engine is the heart of any vehicle, transforming fuel into the power required to keep your car moving forward. Most car engines rely on the internal combustion engine (ICE), a technological marvel that uses the combustion of fuel and air to generate energy.

This process occurs within the engine’s cylinders, where precisely timed explosions drive the pistons, turning the crankshaft and ultimately powering the vehicle.

At its core, the internal combustion engine is a complex and precisely engineered system made up of numerous interworking parts, each performing a unique function.

From the pistons and crankshaft to the valves and camshaft, these components work together to ensure the engine operates efficiently, delivers optimal performance, and withstands the test of time.

Why Do You Need to Know?

Whether you’re a car enthusiast eager to learn more, a mechanic responsible for repairs, or simply someone curious about how cars work, understanding the components of an engine—particularly the internal combustion engine—can provide valuable insights.

This knowledge can help you maintain your vehicle more effectively, identify potential issues early, and optimize its performance for better fuel efficiency and smoother operation.

Get ready to delve into the intriguing world of car engine parts. We’ll uncover the secrets that bring your vehicle to life—and reveal why these components are the unsung heroes of every journey. Buckle up; it’s going to be an exhilarating ride!

Engine Components

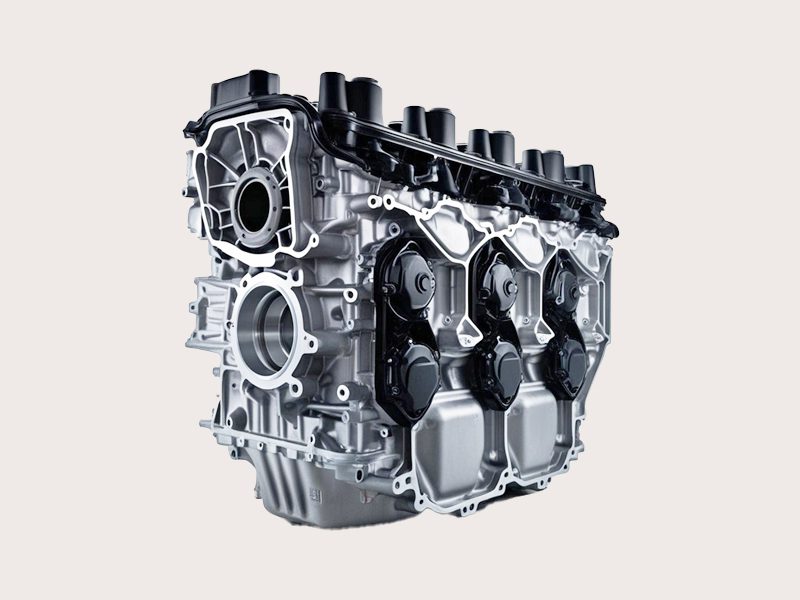

Engine Block

The engine block is the cornerstone of the engine’s structure, serving as a strong and reliable framework that encases vital components like the cylinders, pistons, crankshaft, and often the camshaft.

Its primary role is to provide a solid foundation that supports the engine’s moving parts and withstands the immense pressures generated during combustion.

Typically forged from robust cast iron or lightweight aluminum, the engine block is engineered to endure the intense forces, high temperatures, and constant vibrations that occur during operation, ensuring longevity and reliability.

Ingeniously designed, the block features a network of channels and passageways that allow essential fluids, such as engine oil and coolant, to circulate efficiently. These fluids are crucial for lubricating moving parts, reducing friction, and maintaining the engine’s temperature.

The block also contains spaces for other critical components like the water pump, oil pump, and sometimes even the timing gears. This intricate design ensures the engine block remains structurally sound while supporting efficient fluid circulation and heat management.

With its robust construction and precise engineering, the engine block forms the backbone of the engine, providing a stable and secure foundation for the powerful internal combustion process that propels your vehicle forward.

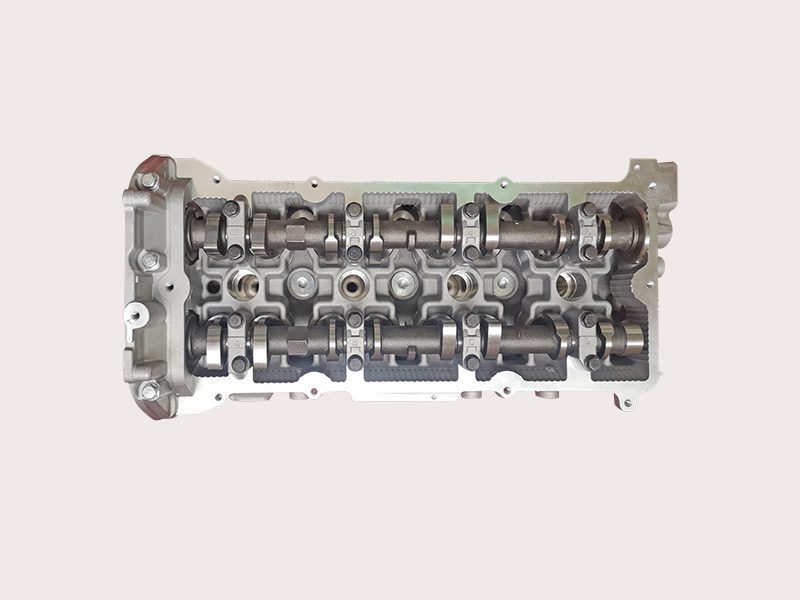

Cylinder Head

The cylinder head rests atop the engine block like a crown, housing crucial components such as intake and exhaust valves, valve springs, lifters, and the camshaft in some engines.

This essential component seals the top of the cylinders and forms the combustion chamber, ensuring smooth and efficient airflow for air, fuel, and exhaust gases throughout the engine.

Precision-engineered, the cylinder head features carefully designed openings, or ports, that allow air and fuel to flow into the cylinders during the intake cycle and guide exhaust gases out during the exhaust cycle.

The cylinder head is also equipped with passages for coolant to flow through, helping to regulate temperature and prevent overheating. The valves, controlled by the camshaft, open and close at precise intervals, while the springs provide the necessary tension to ensure the valves return to their correct position.

This intricate assembly plays a critical role in controlling airflow, maintaining compression within the combustion chamber, and optimizing the engine’s efficiency and power output.

As a key player in the engine’s functionality, the cylinder head ensures smooth and efficient power generation by regulating the timing of the intake and exhaust cycles.

It is indispensable to your vehicle’s overall performance, as even minor defects or malfunctions in the cylinder head can lead to significant loss of power, poor fuel efficiency, and engine misfires.

Cylinder heads are typically made from materials that balance strength, heat resistance, and weight. The most common options are cast iron and aluminum.

Cast iron cylinder heads are known for their durability and heat resistance, making them a popular choice for heavy-duty applications and older engine designs. However, cast iron cylinder heads are heavier than their aluminum counterparts.

Aluminum cylinder heads are lighter, offer better heat dissipation, and are more corrosion-resistant, which makes them ideal for modern vehicles focused on efficiency and fuel economy.

High-performance or racing engines may even use forged aluminum or composite materials to maximize strength while keeping weight low.

The material chosen for the cylinder head depends on the engine’s performance needs, durability requirements, and cost considerations.

Pistons and Crankshaft

Pistons

Pistons are precision-engineered cylindrical components that rhythmically move in an up and down motion within the engine’s cylinders, with piston rings ensuring a tight seal to prevent gas leakage and maintain compression. This motion transforms the explosive pressure of combustion into mechanical energy.

Crankshaft

This energy is then transferred through the connecting rod to the crankshaft, a critical and intricately designed component that serves as the backbone of the engine’s power delivery system, orchestrating the flow of energy throughout the entire engine.

The crankshaft is a long, rotating shaft that stretches the length of the engine, equipped with strategically placed crankpins, counterweights, and journals.

The crankpins act as pivot points, while the counterweights help balance the forces generated during combustion, preventing vibrations and ensuring a smooth rotation. The crankshaft’s design also includes oil passages to ensure proper lubrication of moving parts, preventing friction and wear.

These elements work together to convert the pistons’ up-and-down linear motion into smooth rotational motion.

This rotational motion is transmitted to other essential components, including the flywheel, which stores rotational energy and helps maintain the engine’s momentum during the power stroke, and the timing system, which ensures the synchronized operation of the engine’s valves and other components.

The crankshaft’s durability is paramount, as it endures immense stress, high-speed rotation, and constant exposure to combustion forces during operation. It plays a central role in powering essential engine accessories, such as the alternator and water pump, and, ultimately, in transferring power to the transmission and driving the vehicle’s wheels.

Together, the pistons and crankshaft form a seamless partnership, working in harmony to deliver the force required to bring your car to life and keep it running efficiently. Without their precise interaction, the engine would be unable to generate the power necessary for optimal performance and reliable operation.

Valvetrain and Camshaft

Valvetrain

The valvetrain serves as the engine’s orchestrator, precisely controlling the opening and closing of the intake and exhaust valves to regulate the flow of air and fuel into the cylinders and expel exhaust gases. This precise valve timing is crucial for ensuring efficient combustion and maximizing power output.

The system is composed of various components, including the camshaft, lifters, push rods, rocker arms, and the intake and exhaust valves themselves, all working in harmony to allow the engine to breathe properly.

Camshaft

At the heart of this system lies the camshaft, a meticulously crafted, elongated component housed within the cylinder head. The camshaft features cam lobes that rotate and push against the lifters, which in turn actuate the push rods and rocker arms to open and close the intake and exhaust valves at precise intervals.

Its design and function are critical in determining the timing and duration of valve openings, ensuring that air and fuel enter the cylinders through the intake valve at the right moment and exhaust gases are expelled efficiently through the exhaust valve.

Together, the valvetrain and camshaft work in sync to optimize the engine’s performance, efficiency, and overall power output. The timing of each valve movement affects the engine’s breathing capabilities, throttle response, fuel efficiency, and emissions.

Acting as the maestro of the engine’s mechanical symphony, they ensure that all components perform in perfect harmony, delivering smooth and powerful operation across a range of driving conditions.

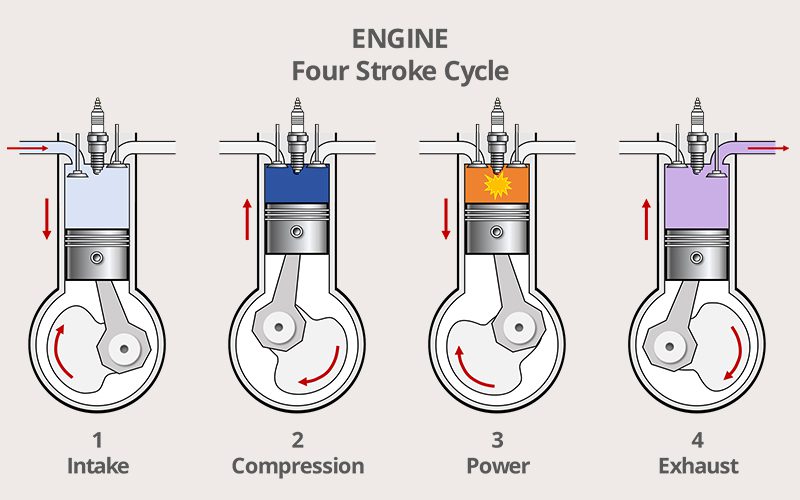

Four Stroke Cycle

The four-stroke internal combustion engine is the most common type of engine used in modern vehicles, renowned for its efficiency and reliability.

This engine operates through a cycle of four distinct strokes—intake, compression, power, and exhaust—each essential to converting fuel into motion.

During the intake stroke, the intake valve opens, and the piston moves downward, pulling in a precise mix of air and fuel into the combustion chamber.

Next, in the compression stroke, the piston moves upward, compressing the air-fuel mixture in the combustion chamber to ready it for ignition.

The magic happens in the power stroke, where the spark plug ignites the compressed fuel in the combustion chamber, causing an explosion that drives the piston downward, generating energy.

Finally, the exhaust valve opens during the exhaust stroke, clearing the combustion chamber, as the piston moves up to expel the burnt gases.

This seamless cycle, repeated thousands of times per minute, is the driving force behind the smooth operation of most vehicles.

The four-stroke internal combustion engine traces its origins to 1876, when Nikolaus Otto developed the first practical version, known as the Otto cycle.

This invention revolutionized engine design by providing a more efficient and reliable way to convert fuel into motion. Its introduction marked a turning point in transportation, enabling the development of compact, powerful, and affordable engines that could be used in everything from automobiles to industrial machinery.

The four-stroke engine’s influence extends far beyond cars, shaping industries, powering innovation, and laying the foundation for modern mobility.

Fuel and Air Delivery System

Air Intake System

The air intake system channels a steady supply of clean, filtered air into the engine, ensuring that only the optimal amount of oxygen reaches the combustion chambers. This air is typically filtered through an air filter that removes dust, debris, and contaminants, protecting sensitive engine components.

Fuel Delivery System

Meanwhile, the fuel delivery system precisely measures and supplies the correct amount of fuel, ensuring it mixes perfectly with the incoming air to form a combustible mixture that enters the combustion chamber.

Throttle Body

At the heart of this process is the throttle body, which plays a critical role in regulating the volume of air entering the engine based on the driver’s input via the accelerator pedal. This throttle body controls the engine’s speed by adjusting the airflow, allowing for smooth acceleration and deceleration.

Fuel Injectors

Fuel injectors are another essential component, responsible for delivering a fine, atomized mist of fuel into the intake manifold. This ensures a uniform and efficient air-fuel mixture, which is crucial for optimal combustion.

The injectors are precisely controlled by the engine’s computer system to adjust the fuel delivery depending on factors such as engine load, temperature, and throttle position.

Engine Lubrication and Cooling

Lubrication System

The lubrication system acts as the engine’s protective shield, minimizing friction between moving parts and preventing wear.

By reducing friction, the system not only ensures smoother operation but also helps maintain the efficiency and longevity of the engine components.

It relies on a steady flow of engine oil, which is pumped by the oil pump and distributed through an intricate network of channels to vital components, such as the pistons, crankshaft, camshaft, and valve lifters.

The oil lubricates these parts, reduces friction, and helps carry away heat generated by combustion. Additionally, the oil helps clean debris and contaminants from engine surfaces, preventing damage and corrosion.

Cooling System

Meanwhile, the cooling system plays a crucial role in keeping the engine from overheating, utilizing a blend of water and coolant (typically a 50/50 mixture of water and antifreeze) to absorb and dissipate excess heat.

The water pump circulates this coolant through the engine’s passages and the radiator, where the heat is transferred to the surrounding air. A thermostat controls the coolant’s temperature, keeping it within the ideal range to maintain optimal engine performance.

If the engine temperature becomes too high, the system activates a fan or opens a valve to increase cooling, preventing overheating. Together, the lubrication and cooling systems work in tandem to maintain the engine’s performance, efficiency, and durability over time.

The Symphony of Power

An engine is like a finely tuned orchestra, where every component plays a specific role in harmony to create the power needed to drive your vehicle.

While each engine part has its own function, it is their synchronized operation that brings the engine to life, ensuring smooth performance, efficiency, and power.

Each part has its specific function, but it’s the coordination between them that enables the engine to perform at its best. From the moment the fuel and air enter the engine, to the combustion process, to the transformation of energy into rotational power, every detail matters.

Understanding how these parts work together not only helps you appreciate the complexity of your engine but also allows for better maintenance and troubleshooting to keep your engine running at its peak.

Engine Maintenance and Troubleshooting

Now that we’ve explored the intricate structure of an engine and how its components work in harmony, let’s shift gears to understand the importance of proper maintenance in keeping this complex system running smoothly and efficiently.

Regular Maintenance

Regular maintenance is crucial to preserving the health of your engine and avoiding expensive repairs.

This includes routine tasks like changing the oil, replacing air and fuel filters, inspecting spark plugs, and ensuring proper coolant levels to keep the engine running smoothly.

Common Issues

Common engine issues, such as an improper fuel mix, loss of compression, or ignition failure, often stem from underlying problems like faulty fuel pumps, clogged fuel filters, worn-out spark plugs, or damaged valve or piston rings.

Over time, carbon buildup, overheating, or neglecting small issues can exacerbate these problems, leading to more serious failures.

Key to Peak Performance

By staying on top of maintenance schedules, performing regular inspections, and addressing potential issues early, you can extend the engine’s lifespan and keep it running at peak performance.

A well-maintained engine not only ensures reliability and efficiency but also delivers better fuel economy and reduces harmful emissions, making it a win for both your vehicle and the environment.

For detailed guidelines on maintaining a high-performance engine, refer to the Society of Automotive Engineers (SAE), which sets industry standards.

Conclusion

In this article, we’ve walked you through the essential parts of a car engine, from the engine block that holds everything together to the valvetrain, the air-fuel delivery systems, and the lubrication and cooling mechanisms that keep everything running smoothly.

Each of these components plays a key role in your engine’s performance and lifespan. Regular maintenance is crucial for preventing costly repairs and ensuring your engine runs at its best for years to come.

At Woda, we specialize in high-quality automotive engine parts designed to keep your vehicle running smoothly and efficiently. Whether you’re a car enthusiast or a professional in the field, our durable and reliable parts are built to perform. If you are searching for a trusted auto engine parts supplier, don’t hesitate to contact us now.