Car carbon build up is one of the most common—and often overlooked—issues that can quietly sabotage an engine’s performance over time. It sneaks up on both older and newer engines, gradually reducing efficiency and increasing the risk of long-term damage.

Whether you’re managing a fleet of vehicles, operating an auto repair shop, or distributing engine components, understanding carbon build up is essential. Addressing it early ensures engines run smoother, last longer, and perform within OEM standards.

Understanding Carbon Build up

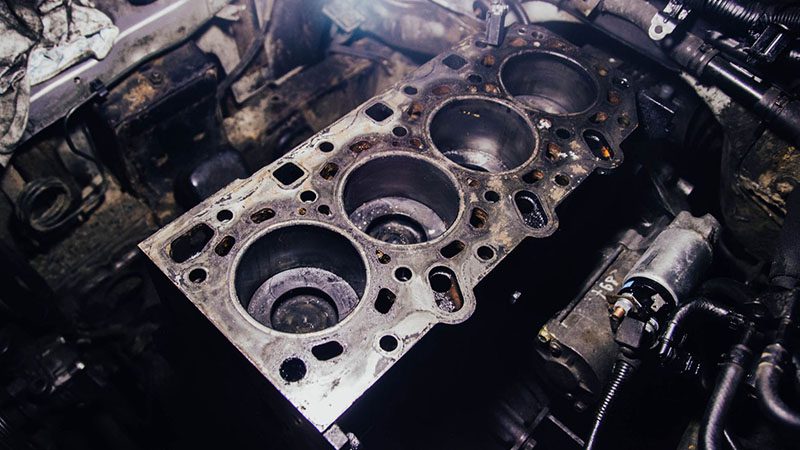

At its core, carbon build up is a natural by-product of incomplete fuel combustion. When fuel doesn’t burn completely, it leaves behind tiny particles of black soot. Over time, this soot hardens into crusty deposits on critical engine components like intake valves, piston crowns, and combustion chambers.

In combustion engines, carbon builds as a result of burning fuel, especially when using low-quality fuel or under stop/start driving conditions. These deposits can restrict airflow, disrupt the air-fuel mixture, and force the engine to operate under suboptimal conditions.

The intake manifold plays a vital role in the combustion process by channeling the air-fuel mixture into the engine’s cylinders. In older engines, fuel flows through the intake manifold, which can help clean it, whereas direct injection systems may lead to carbon accumulation on intake valves.

Carbon buildup forms in the engine’s cylinders as a by-product of the combustion process, particularly when fuel combustion is incomplete. If left unchecked, carbon build up can lead to rough idling, cold start problems, increased emissions, and even engine failure.

That’s why regular maintenance and early intervention are essential to prevent long-term performance issues.

Symptoms of Carbon Buildup

Carbon buildup can manifest in various ways, often starting with subtle signs that gradually worsen if left unaddressed. Here are some common symptoms to watch out for:

- Engine Performance Issues: One of the earliest signs of carbon buildup is a noticeable drop in engine performance. You might experience reduced power and sluggish acceleration, making your vehicle feel less responsive.

- Engine Vibration: Excessive carbon deposits can cause engine vibration, leading to an uncomfortable driving experience. This vibration can also stress other engine components, potentially causing further damage.

- Cold Start Misfires: If your engine struggles to start or misfires during cold starts, it could be due to carbon buildup. These misfires are often a sign of more serious underlying issues that need immediate attention.

- Reduced Fuel Efficiency: Carbon buildup can interfere with the air-fuel mixture, causing the engine to consume more fuel than necessary. This leads to decreased fuel efficiency, meaning you’ll spend more time and money at the gas pump.

- Increased Emissions: As carbon deposits accumulate, they can cause incomplete combustion, resulting in higher emissions. Not only does this harm the environment, but it can also cause your vehicle to fail emissions tests.

- Engine Knock or Pinging: Carbon buildup can create hotspots in the combustion chamber, leading to engine knock or pinging. These sounds are not just annoying; they indicate that your engine is under stress and could suffer damage if not addressed.

- Reduced Engine Lifespan: Over time, excessive carbon buildup can significantly reduce your engine’s lifespan. These deposits can accelerate wear on critical engine components, potentially leading to expensive repairs or even complete engine replacement.

Causes of Engine Carbon Build up

Understanding what causes carbon deposits can help you prevent them in the first place. Here are the most common culprits:

- Low-Quality Fuel: Substandard fuel often contains impurities that don’t burn completely, leaving behind sticky carbon residues.

- Stop-and-Go Driving: Short trips and city driving prevent the engine from reaching optimal operating temperature, impairing DPF (Diesel Particulate Filter) regeneration and leading to carbon accumulation. Operating the engine at the correct operating temperature is crucial to prevent carbon buildup.

- Poor Maintenance Habits: Skipping oil changes, ignoring dirty filters, or delaying scheduled servicing allows soot to build up faster than it can be burned off. Proper maintenance of the cylinder head is essential to avoid carbon buildup.

- Direct Injection Engines (GDi): Engines that use gasoline direct injection are particularly prone to buildup because the fuel is injected directly into the combustion chamber, bypassing the intake valves where traditional fuel spray can help clean carbon off. Maintaining the intake valve is significant to prevent carbon buildup.

- Faulty Fuel Systems: Malfunctioning fuel injectors or a weak fuel pump can cause incomplete combustion, increasing carbon deposit formation.

Effects of Carbon Build up on Engine Performance

Even small amounts of carbon can throw off the balance of an engine. Here’s how:

- Disrupted Airflow: Deposits around valves or intake ports reduce air passage, causing unbalanced combustion. If the buildup reaches extreme levels, it can severely hinder engine performance and may require specific fuel additives to clean the engine.

- Inconsistent Air-Fuel Ratios: Uneven combustion can create hotspots, which damage components and reduce fuel efficiency. Carbon buildup in the exhaust valves can further disrupt the combustion process, leading to decreased engine performance.

- Increased Vibration & Noise: Carbon deposits can cause misfires, leading to engine knocking and uncomfortable vibration. More carbon deposits can exacerbate these issues, resulting in increased vibration and noise.

- Higher Emissions & Fuel Consumption: The engine works harder to overcome restrictions, burning more fuel and releasing more pollutants.

Removing Carbon Build up and Preventing Build Up

Tackling carbon buildup doesn’t always require a complete engine teardown. For moderate buildup, here’s how to handle it:

- Safety First: Always wear solvent-proof gloves and eye protection when working with carbon removal chemicals.

- Use the Right Tools: A wooden or plastic scraper and a fine steel wool pad, along with an OEM-approved solvent, can safely remove carbon from metal surfaces without damaging aluminum or plastic parts. It is also important to inspect the surfaces of the engine components like the cylinder head and valve seats for any damage before reassembly.

- Clean Gently: Soak carbon-affected areas with solvent, scrape off softened deposits, then wipe clean. If the cylinder head is difficult to remove, gently striking the side with a nylon-faced hammer can help to loosen it.

- Remove Carbon Deposits: Soak carbon-affected areas with solvent, scrape off softened deposits, then wipe clean. Ensure all carbon buildup is effectively removed without damaging the aluminum and plastic parts.

- Fuel Treatments: Periodic use of high-quality fuel additives helps dissolve carbon before it hardens, especially useful in direct-injection engines.

Regular Maintenance Practices

Preventing carbon buildup is all about consistent and proactive maintenance. Here are some essential practices to keep your engine running smoothly:

- Regular Oil Changes: Changing your oil at the manufacturer-recommended intervals is crucial. Fresh oil helps remove contaminants and debris that can contribute to carbon buildup, ensuring your engine stays clean.

- Fuel Additives: Using high-quality fuel additives can help keep your engine and fuel system clean. These additives work by dissolving carbon deposits before they harden, making them easier to burn off during normal engine operation.

- Spark Plug Replacement: Regularly replacing your spark plugs ensures proper combustion. Worn or dirty spark plugs can lead to incomplete combustion, increasing the risk of carbon buildup.

- Air Filter Replacement: A clean air filter is essential for proper airflow and combustion. Replacing your air filter regularly helps prevent debris from entering the engine, reducing the likelihood of carbon deposits forming.

- Engine Cleaning: Periodic engine cleaning can remove contaminants and debris that contribute to carbon buildup. Using an engine cleaner designed for your specific engine type can help maintain optimal performance.

- PCV System Maintenance: The Positive Crankcase Ventilation (PCV) system helps ventilate the engine and prevent pressure buildup. Regular maintenance of the PCV system ensures proper engine ventilation, reducing the risk of carbon deposits.

- Fuel Injector Cleaning: Keeping your fuel injectors clean is vital for proper fuel flow and combustion. Regular cleaning of the fuel injectors helps prevent carbon buildup, ensuring your engine runs efficiently.

By following these regular maintenance practices, you can significantly reduce the risk of carbon buildup and keep your engine in top condition.

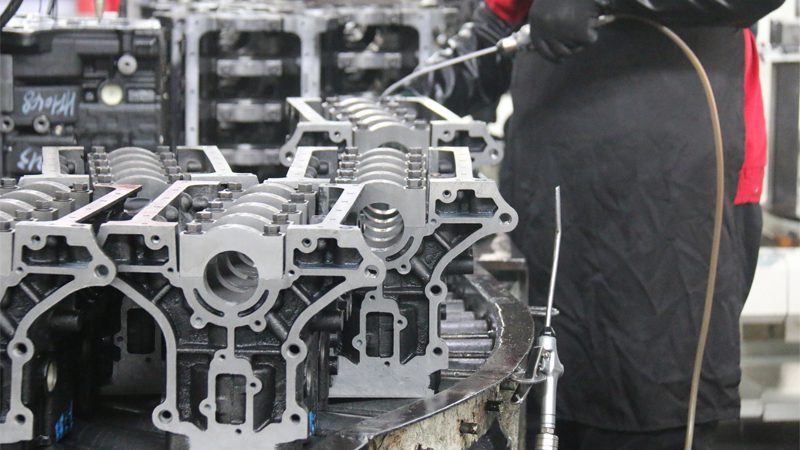

Addressing Extreme Cases of Carbon Build up

In more severe cases, where carbon deposits have accumulated over years of poor maintenance, professional intervention may be necessary:

- Engine Decarbonization Services: These use specialized chemicals or machines to remove deep-seated carbon without disassembly. It is crucial to service the motor regularly to prevent severe carbon buildup.

- Component Replacement: Severely clogged EGR valves, injectors, or cylinder heads may require replacement. Ensure the correct position of the new head gasket during reassembly to avoid improper sealing.

- Additive-Based Solutions: Fuel system cleaners like AFC (Advanced Fuel Conditioner) can help break down stubborn carbon over time. Cleaning metal parts is essential to maintain engine efficiency.

- Use Quality Oil & Fuel: Stick to manufacturer-recommended oil grades and high-quality fuels to support cleaner combustion.

Advanced Methods for Engine Carbon Cleaning

For engine owners seeking the most effective results, advanced cleaning solutions are available:

- Chemical Treatments: Involve powerful solvents that break down carbon but require precise application to avoid damage.

- Walnut Blasting: A highly effective mechanical cleaning method where crushed walnut shells are blasted at intake valves to remove carbon. The manifold plays a crucial role in the fuel delivery system, and carbon buildup in the manifold can significantly impact engine performance.

- Hydrogen Carbon Cleaning (HHO): Eco-friendly and non-invasive, this method uses hydrogen and oxygen to remove carbon via the intake system. Regular maintenance, including cleaning the pistons, is essential to ensure optimal engine performance and prevent issues such as knocking or overheating.

- Professional Service Costs: Expect professional decarbonization services to range between $100–$300 depending on your engine type and condition. Using the right equipment for advanced cleaning methods is crucial to effectively address carbon buildup and perform maintenance tasks safely.

Conclusion

Carbon build up may seem minor at first, but over time it can seriously impact your engine’s performance, reliability, and lifespan. Regular inspections, proper fuel and oil usage, and preventative maintenance go a long way in keeping your engine running clean and strong.

At Nanjing Woda Auto Technology Co., Ltd., we specialize in high-quality OEM and aftermarket automotive engine parts, providing solutions that enhance engine performance and reliability.

With a strong focus on innovation and quality, we offer a wide range of products designed to meet the needs of automotive businesses worldwide. Trust us for your engine parts needs and experience the power of professional support and timely delivery.