Modern internal combustion engines are all about airflow. The more efficiently an engine breathes, the more power it can produce. That’s why cylinder head porting — a process that reshapes the intake and exhaust passages to improve airflow — remains one of the oldest yet most effective performance upgrades in engine building.

For workshops, tuners, and engine-parts suppliers, understanding how cylinder head porting works isn’t just about horsepower numbers. It’s about balancing efficiency, reliability, and value. In this guide, we’ll explain what porting actually is, how it’s done, when it’s worth it, and what pitfalls to avoid.

What Is Cylinder Head Porting?

Cylinder head porting refers to the process of modifying the internal passages (ports) of the cylinder head to improve the way air and fuel enter — and exhaust gases leave — the combustion chamber.

Every cylinder head has a series of cast runners:

- Intake ports feed the air–fuel mixture from the intake manifold into the combustion chamber.

- Exhaust ports expel burnt gases out through the manifold.

In most factory heads, these ports are designed with mass production and emissions in mind, not maximum flow. Small irregularities, rough surfaces, and sharp turns restrict airflow — and that limits how efficiently an engine can fill its cylinders.

Porting corrects those imperfections. By carefully removing material and smoothing the port surfaces, the technician reduces turbulence and improves airflow velocity. The result is a cylinder head that “breathes” better, allowing the engine to burn fuel more completely and produce more power per stroke.

Why Port Cylinder Heads? (Benefits and Gains)

The main reason for porting is simple: more efficient airflow equals more power.

A properly ported cylinder head can:

- Increase volumetric efficiency — improving how much air–fuel mixture enters the cylinder.

- Enhance combustion — better mixture distribution leads to more complete burn.

- Boost horsepower and torque, especially at higher RPM.

- Support other upgrades such as performance cams, exhaust systems, or forced induction.

On average, professional porting can improve flow by 10–25%, depending on the head design and how restrictive the original casting is. That can translate to 5–15% more horsepower when matched with the right intake, camshaft, and exhaust setup.

Efficiency, Not Just Power

Another overlooked benefit is engine efficiency. Better airflow often means less pumping loss — the effort the engine uses just to move air in and out. This can lead to smoother throttle response, slightly better fuel economy, and lower exhaust temperatures.

For professional workshops and B2B buyers, offering ported heads or engines with improved airflow can also become a value-added product line, appealing to performance-oriented customers or heavy-duty applications where efficiency matters.

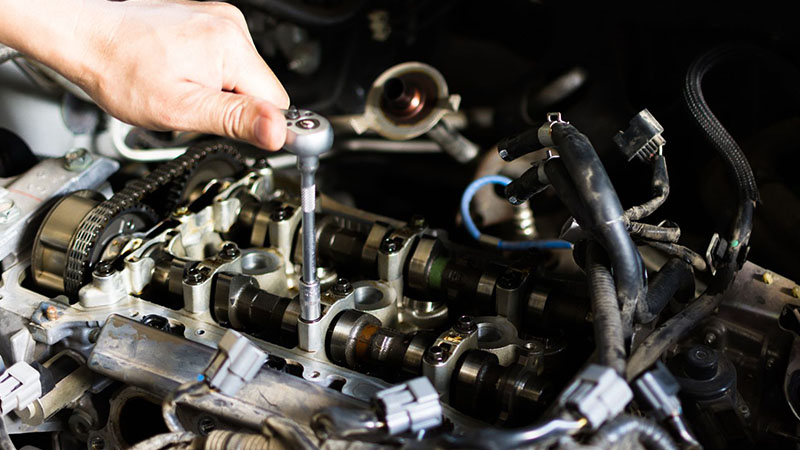

How Cylinder Head Porting Works

Porting isn’t simply grinding metal to make passages larger. It’s about reshaping and optimizing flow paths for a balance between velocity and volume. A bigger port isn’t always a better one — too much enlargement can slow down airspeed and reduce low-end torque.

Let’s look at how professionals do it.

1. Inspection and Flow Benchmark

Before touching the head, the technician inspects casting quality, valve seats, and gasket surfaces. Many shops use a flow bench, a test device that measures how much air passes through each port at different valve lifts. This provides a baseline to identify restrictions.

2. Mapping the Ports

Next, the ports are marked with layout dye to identify high and low spots. The goal isn’t a mirror finish but a consistent, smooth contour that minimizes turbulence and maintains velocity.

3. Material Removal and Shaping

Using carbide burrs and abrasive rolls, the technician carefully removes small amounts of material — typically less than a millimeter in key areas like:

- The bowl area (just below the valve seat)

- The short-turn radius (where the port curves sharply toward the valve)

- The throat and valve guide boss (to reduce obstruction)

In performance engines, these small adjustments can significantly improve flow behavior.

4. Port Matching

The intake and exhaust ports are then aligned with the corresponding manifolds — a step known as port matching. Even a small misalignment between gasket surfaces can create turbulence and restrict flow.

5. Surface Finishing

Contrary to popular belief, the goal isn’t a mirror-polished surface. A slightly rough texture on the intake side helps maintain air–fuel mixture atomization. The exhaust side, however, benefits from a smoother finish to prevent carbon buildup.

6. Validation and Testing

After shaping, the head is flow-tested again to confirm measurable improvement. Professional shops record flow data for each port to ensure consistency — something critical in race engines and high-performance builds.

Hand Porting vs. CNC Porting

There are two main approaches to porting:

| Type | Description | Advantages | Drawbacks |

|---|---|---|---|

| Hand Porting | Skilled technician manually shapes ports using air tools. | Flexible, ideal for custom applications or prototypes. | Time-consuming, hard to maintain uniformity across cylinders. |

| CNC Porting | Computer-controlled milling replicates an optimized port design. | High precision, consistency, faster turnaround. | Expensive setup cost, requires 3D scanning and programming. |

Many professional builders today use CNC porting for production heads, then perform hand blending to fine-tune small areas. For B2B suppliers, CNC porting also enables repeatable quality — important when offering ported heads as a standard product.

When Should You Port Cylinder Heads?

Porting isn’t a universal fix. Whether it’s worthwhile depends on the engine’s purpose and setup.

Ideal Scenarios

- Performance builds — turbocharged, supercharged, or high-RPM naturally aspirated engines.

- Racing applications — where every bit of airflow counts.

- Heavy-duty engines — where improving efficiency helps reduce fuel use.

- Upgraded engines — when installing larger valves, performance cams, or aftermarket manifolds.

When It May Not Be Worth It

- Stock daily-driven cars that rarely rev high.

- Engines with restrictive intake/exhaust systems that limit benefits.

- Situations where porting cost exceeds power gains (e.g., mild street tune).

As a rule of thumb, porting makes the most sense after other airflow-related upgrades are in place. There’s little point in porting a head if the intake or exhaust system remains restrictive.

Cost and Time Considerations

Porting requires skill, precision, and hours of labor. Prices vary widely depending on region, head type, and whether it’s hand or CNC ported.

Typical market ranges:

- Hand porting: $400 – $800 per set for basic street heads.

- CNC porting: $700 – $1,500 + for race or high-performance heads.

- Flow testing and valve work may add $200 – $400 more.

Professional shops may spend 15–40 hours on a full port and polish job. The result, however, is often worth it for performance or specialized B2B clients.

When comparing costs, always factor in:

- Expected horsepower gains.

- Engine reliability and warranty implications.

- Downtime if heads must be shipped out.

For distributors and importers, pre-ported heads can be a smart addition to a product lineup — especially for engines like Toyota 2TR, Nissan QR25, or Isuzu 4JB1-T, where airflow improvements are measurable and market demand exists.

Common Mistakes and Risks

Even experienced builders can make costly mistakes during head porting. Here are the most frequent issues to watch for:

- Over-porting – Removing too much material reduces port velocity, killing low-RPM torque and drivability.

- Asymmetry – Inconsistent port shapes between cylinders cause uneven airflow and misfires.

- Damaged valve seats or guides – Aggressive grinding near these areas can ruin sealing surfaces.

- No flow verification – Skipping flow-bench testing makes it impossible to measure real improvement.

- Improper tool use – Wrong burr type or speed can gouge the port or cause stress cracks.

For workshops, maintaining before-and-after flow data and using calibrated tools helps ensure repeatable results. For buyers, always request documentation or sample flow charts from suppliers before purchasing ported heads.

Best Practices for Workshops and B2B Buyers

If you’re in the business of supplying or rebuilding engines, cylinder head porting can become a competitive advantage — provided it’s approached correctly.

For Workshops

- Invest in proper equipment: flow bench, lighting, precision tools.

- Train staff to understand airflow dynamics — not just grinding technique.

- Keep records of port shapes, lift values, and performance results.

- Educate customers about realistic expectations (no miracle power jumps).

For Distributors and Suppliers

- Partner with trusted machine shops offering CNC porting services.

- Offer “ported-ready” heads — pre-machined castings optimized for port work.

- Market with data: share flow-bench numbers and dyno graphs to build confidence.

- Ensure quality control: all heads should be tested for uniform flow before shipment.

FAQ

What does cylinder head porting actually do?

It reshapes the intake and exhaust passages to reduce restrictions, allowing the engine to draw in and expel air more efficiently — resulting in better combustion and more power.

How much horsepower can you gain from porting?

Typically 5–15% depending on the engine design and supporting modifications. Gains are most noticeable on high-RPM or forced-induction builds.

Can you port heads yourself?

It’s possible with the right tools and patience, but risky. Without experience or a flow bench, it’s easy to remove too much material or ruin the head.

Is porting worth it for a street engine?

For mild builds, the gains might not justify the cost. But for performance or efficiency-focused applications, it’s one of the most cost-effective ways to enhance airflow.

Will porting affect reliability?

When done professionally, porting doesn’t harm reliability. Poorly executed porting, however, can weaken casting walls or valve seats.

Conclusion

Cylinder head porting is as much art as it is science. Done right, it unlocks the hidden potential of an engine by improving how efficiently it breathes. Whether you’re tuning for performance, improving efficiency, or supplying upgraded engine components, understanding porting helps you make smarter decisions.

About Us

At Nanjing Woda Auto Technology Co., Ltd., we specialize in high-quality cylinder heads, long blocks, short blocks, and precision components for professional engine rebuilders and distributors worldwide. Our products are engineered for strength, consistency, and compatibility — perfect for customers who need reliable parts for performance tuning or porting applications.

Looking to source port-ready heads or complete engines?

Contact Woda Auto today to explore our range or request a customized quotation.