Automotive engine action or performance heavily relies on cylinder heads. It’s an integral component with many crucial responsibilities. A damaged cylinder head means partial to complete disruption of smooth engine operability.

Several reasons can call for repair, rebuild, or even replacement. Each strategy features an exclusive range of costs with distinctive considerations. The article covers the possible cylinder head replacement cost in 2025 with intuitive details.

Why You Must Choose Early Diagnosis?

Don’t underestimate those tiny cracks or minor warping. They may start small but escalate quickly. A neglected crack can widen under heat and pressure.

Ignoring the issues leads to catastrophic damage, even complete engine failure. And you may end up paying/charging thousand dollars for something that could cost $300.

Signs/Warnings/Traits that Need Immediate Attention

1. Severe Overheating Symptoms –

- Temperature gauge redlining.

- Steam from under the hood.

- Engine shutdown due to heat.

Overheating can warp aluminum heads. Aluminum cylinder heads warp at temperatures above 250°F (121°C). Valves, pistons, and gaskets also lose workability. Continued driving under the conditions can lead to irreversible damage.

2. Loss of Coolant Symptoms –

- Milky oil (coolant contamination).

- Empty coolant reservoir with no visible leaks.

- Frequent need to top off coolant.

It causes overheating and hydrolock, where incompressible fluid prevents piston movement. A blown head gasket can leak 0.1 to 1 gallon/hour of coolant, depending on severity.

3. Loss of Power Symptoms –

- Thick white smoke from exhaust (at startup).

- Sweet smell from exhaust valves.

- Engine misfires or sluggish acceleration.

Combustion, contamination and compression loss quickly escalate to engine failure. White smoke and power loss mean coolant burning. You can notice internal damage that disrupts engine security.

Cost to Replace an Engine Cylinder Head

1. Average replacement expense by vehicle type –

- Economy Cars: $800 – $1500.

- Mid-Range Vehicles: $1200 – $2500.

- Luxury Vehicles: $2000 – $4000+.

- Trucks/SUVs: $1500 – $3500.

Each one covers the parts cost as well as labor charges. For example, replacing a Toyota Camry may cost around $1300. Meanwhile, a BMW X3 can exceed $3000 depending on the car engine’s complexity.

2. Standard parts cost analysis –

- New Cylinder Head: $300 – $1500.

- Gasket Set: $50 – $200.

- Head Bolts: $30 – $100.

- Valves, Seals, Springs: $100 – $400.

OEM vs Aftermarket vs Remanufactured Parts

OEM parts come with guaranteed compatibility at premium pricing. More affordable aftermarket parts may vary in quality. Remanufactured heads can save 30% – 50% compared to new OEM units.

3. Important labor cost factors –

- Labor Hours: 8 – 15 hours depending on engine design.

- Hourly Rates: $80 – $150 per hour, depending on region and shop.

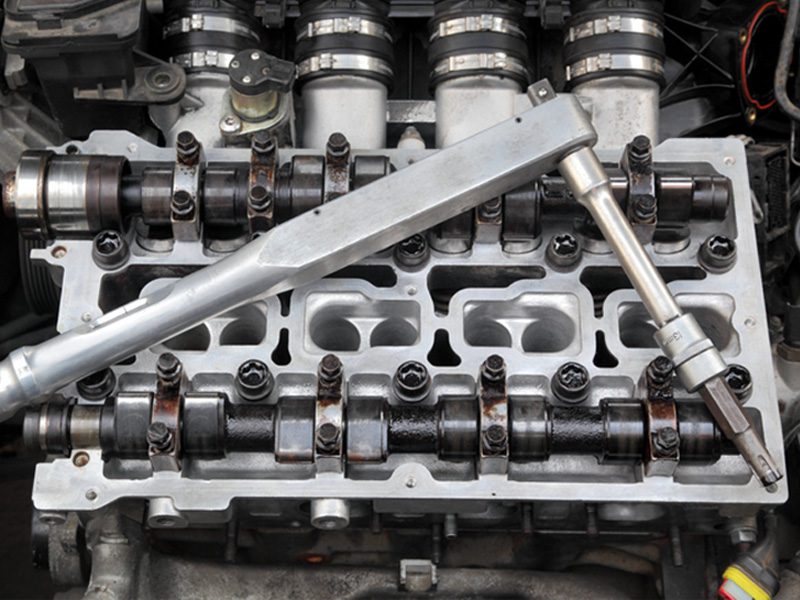

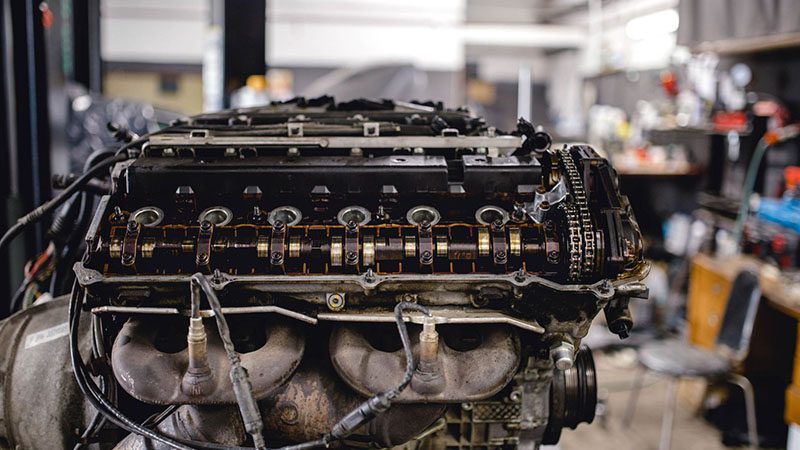

- Complexity Variables: V-type engines require more disassembly. Overhead camshaft designs may need camshaft removal. Additional costly repairs (valve damage/timing components) can take more time.

4. Additional costs to consider –

- Machine Shop Services: $75 – $200.

- Fluids and Filters: $50 – $100.

- Diagnostic Fees: $100 – $150.

Resurfacing the head can ensure a proper seal. Coolant and oil replacement are mandatory after every disassembly. Pressure testing can confirm the integrity of the head.

Cylinder Head Assembly: Repair Cost

Repairing seems like a reasonable option with –

- Least warping that can be corrected via machining.

- Minor cracks in non-critical sections.

- Damaged head gasket surfaces with an intact cylinder.

For instance, a mildly warped aluminum head from a Honda Accord may only need resurfacing. In contrast, a cast iron head with a small crack near the cooling system (coolant passage) is weldable.

Common Repair Methods

- Machining/Skimming ($75 – $200): Resurfacing the mating surface to restore flatness and sealing.

- Welding Cracks ($150 – $500): TIG or MIG welding to fill cracks, especially in aluminum heads.

- Pressure Testing ($50 – $150): Holding compression by the head and coolant without any leaks.

- Pinning/Plugging ($100 – $300): Drilling and inserting metal pins in cast iron heads to seal cracks.

Factors to Influence Repair Pricing

- Severity: Deep cracks or multiple fractures require more labor. You may need welding and machining.

- Labor Intensity: Complex engine layouts (V6 or DOHC) increase disassembly time and cost.

- Material Type: Aluminum heads are easier to machine but more prone to cracking. Cast iron heads are durable but harder to weld.

- Vehicle Make and Model: Luxury or performance vehicles often need specialized parts and expertise.

Cylinder Head Rebuild Price

Some issues (valve damage, warping, or carbon buildup) aren’t beyond expensive repair. However, a rebuild seems more economical for such cases. Rebuilding restores the cylinder head to good condition. The process features –

- Disassembly and Cleaning: Removing carbon deposits, sludge, and debris.

- Machining/Resurfacing: Flattening the mating surface to restore proper sealing.

- Valve Work: Replacing or regrinding valves, valve seats, and guides.

- Seal Replacement: Installing new valve seals and gaskets.

- Pressure Testing: Ensuring the head holds compression and coolant without leaks.

Specialized machine shops or engine rebuilders can note down radiator conditions to fix the issues. Professional services can restore the performance without higher costs.

Average Rebuilding Expense (Including Labor Costs)

- Cleaning and Inspection: $50 – $150.

- Machining/Resurfacing: $75 – $200.

- Valve and Seal Replacement: $150 – $400.

- Pressure Testing: $50 – $150.

- Labor (Disassembly/Reassembly): $100 – $300.

Rebuilding a cylinder head on a Toyota 4Runner may cost around $700. A BMW X3 can cost $1200 due to more complex valve systems and aluminum head machining requirements.

Benefits of Rebuilding Over Replacement

- Cost-Effective: Rebuilding can save 30% – 60% compared to buying a new OEM head.

- Preserves Original Components: Especially valuable for a specific vehicle (classic or rare).

- Environmentally Friendly: Reduces waste by reusing viable parts.

- Customizable: Allows for performance upgrades like porting or stronger valve springs.

When Is Rebuilding Recommended?

Rebuilding is ideal when –

- The head is structurally okay (no major cracks).

- Valves or seals are worn but replaceable.

- Warping is minimal and correctable through machining.

- You want to retain OEM parts or improve performance.

Repair vs Rebuild vs Replace: Cost Comparison 2025

1. Cylinder Head Repair

Cost Range: $500 – $1200

Applicability –

- Minor cracks in non-critical areas.

- Surface warping that can be machined.

- Valve seal or gasket issues.

Methods –

- Machining (resurfacing the head deck).

- Welding (TIG for aluminum, flame spray for cast iron).

- Pressure Testing to ensure sealing integrity.

Limitations –

- Repairs may not hold under high stress or heat.

- Welding can alter head geometry if not done precisely.

- Not suitable for heads with multiple or deep cracks.

2. Cylinder Head Rebuild

Cost Range: $800 – $2000

Applicability –

- Complete disassembly and cleaning.

- Machining of surfaces and ports.

- Replacement of valves, seals, springs, and guides.

- Pressure testing and reassembly.

Benefits –

- More thorough than repair.

- Preserves original head casting.

- Ideal for performance tuning or restoration.

Downsides –

- Labor-intensive and time-consuming.

- Not viable if the head is cracked beyond repair.

3. Complete Cylinder Head Replacement

Cost Range: $1000 – $4000+

Applicability –

- Severe cracks or warping.

- Multiple component failures.

- Failed previous repairs or rebuilds.

Advantages –

- Restores complete engine integrity.

- Often comes with a warranty (OEM or remanufactured).

- Eliminates the risk of hidden damage.

Considerations –

- Labor-intensive (6 – 15 hours).

- May require removal of camshaft, manifolds, and timing components.

Simplified Cost Comparison Table: Repair vs Rebuild vs Replacement

| Option | Cost | Applicability | Limitation | Time Requirement |

|---|---|---|---|---|

| Repair | $500 - $1200 | Minor cracks + gasket issues | Low stress-holding capability | 4 – 8 hours |

| Rebuild | $800 - $2000 | Worn valves + seals + warping | Not for severe cracks | 8 – 12 hours |

| Replacement | $1000 - $4000+ | Severe damage + multiple failures | Excessive downtime | 10 – 15 hours |

Factors to Influence Replacement Cost for a New Head

1. Vehicle-Specific Factors

- Make and Model: Domestic vehicles (Ford, Chevrolet) have more affordable parts. Imports (BMW, Audi, Subaru) tend to have higher parts costs and more complex engine layouts.

- Engine Configuration: Inline engines with one head reduce parts and labor. V-type engines (V6/V8) with two heads double the parts cost and increase labor.

- Age of Vehicle: Older vehicles may have limited parts availability, especially for OEM heads. Rare or discontinued models may require remanufactured or custom-machined heads.

2. Geographic Location

- Regional Labor Rate Variations: Labor rates range from $80 to $150/hour, depending on region. Urban areas (New York, Los Angeles) tend to have higher shop rates than rural towns.

- Urban vs Rural Pricing Differences: Urban shops may charge more due to overhead and demand. Rural shops may offer lower rates but could lack specialized equipment or experience.

3. Shop Type and Quality

- Dealership vs Independent Shop: Dealerships often charge premium rates but offer OEM parts and warranties. Independent shops may be more affordable but vary in expertise.

- Speciality Shops vs General Repair: Engine rebuilders or machine shops specialize in cylinder head work and may offer better precision. General repair shops may outsource machining, adding time and cost.

- Warranty Considerations: OEM replacements often come with 1 – 3-year warranties. Rebuilt or remanufactured heads may include limited warranties, depending on the shop.

4. Extent of Damage

- Single vs Multiple Cylinder Heads: Inline engines have one head against V-type engines’ 2 heads. Replacing both heads can double the parts cost, though labor may only increase slightly.

- Associated Component Damage: Cracked heads often damage valves, pistons, or gaskets. Additional repairs (timing components, camshafts) can add $500 – $1500 to the total.

DIY vs Professional Installation

Replacing cylinder heads is complex and critical. You must understand the trade-offs from the get-go.

1. DIY Considerations

The advanced-level repair requires knowledge of engine timing, torque specs, and gasket sealing. Even experienced DIYers often consult professional guides or videos.

Expect to spend 15 – 25 hours depending on your experience and engine complexity. This includes disassembly, cleaning, installation, and reassembly.

Labor costs for professional installation range from $600 to $1500. DIYers can save this amount, paying only for parts (usually $200 – $800).

2. Risks of DIY Approach

Mistakes in bolt torque or gasket alignment can lead to warping, leaks, or engine failure. Timing components must be reinstalled precisely to avoid misfires or valve damage.

Incorrect installation can cause coolant leaks, compression loss, or cracked heads. A warped head due to improper torque can cost $500 – $1200 to resurface or replace.

DIY repairs typically void manufacturer warranties. Aftermarket cylinder head parts may offer limited warranties. It’s only applicable when installed by certified professionals.

3. When to Choose Professional Installation

V6, V8, or turbocharged engines often require the removal of multiple components and precise timing. Professionals have access to diagnostic tools and engine lifts that streamline the process.

Dealerships and certified shops offer OEM parts with 1–3 year warranties. This ensures peace of mind and protects resale value.

Professionals complete the job in 6 – 15 hours, often within a day or two. DIY projects may stretch over multiple weekends, especially if complications arise.

When Is It Better to Replace the Entire Engine?

The cracked cylinder head also incurs damage to pistons, valves, camshafts, or the engine block. Severe overheating can lead to compression loss, coolant contamination, and internal scoring.

Mechanics recommend engine replacement when damage affects more than 40% of internal components. Engines over 150K – 200K miles are more prone to wear across multiple systems.

Replacement alone can’t restore performance with worn rings, bearings, or seals. A remanufactured engine can add 100K+ miles of life to a vehicle, making it a wise investment for long-term use.

When the car’s market value is under $5000, investing $2000+ in head replacement isn’t beneficial. In such cases, a used or remanufactured engine may induce better performance and resale value.

FAQ

How long does it take to replace a cylinder head?

Expect 6 to 15 hours of labor time. Simpler engines may take less time. Complex or V-type engines require more disassembly and precision work.

How is a cylinder head replaced?

The process involves –

- Removing obstructing components (air intake, throttle body, etc.).

- Detaching the head from the block.

- Cleaning and inspecting mating surfaces.

- Installing a new head with proper torque specs.

- Reassembling and testing the engine.

Can a cylinder head be replaced without removing the engine?

Yes. Though it depends on the engine design. In OHV engines, rocker arms must be detached. In OHC engines, the camshaft may need complete removal, which can be labor-intensive.

What does cylinder head resurfacing cost?

Resurfacing typically costs $300 to $2000, depending on the extent of damage. Pressure testing adds another $150+ per head, especially if cracks or warping are suspected.

What are the signs that a cylinder head needs replacement?

Common symptoms include –

- White smoke from the exhaust.

- Coolant loss with no visible leaks.

- Engine overheating.

- Loss of power or misfires.

These signs mostly indicate cracks, warping, or gasket failure.

Should both cylinder heads be replaced in a V6 or V8 engine?

Not always. If only one head is damaged, replacing that side may suffice. Some mechanics recommend replacing both when the engine has high mileage or an overheating history.

Conclusion

Damages to cylinder heads can give you quite the scare, financially as well as mentally. Early detection and intervention are the ultimate ways to avert any costly automotive crises. The more ignorant you become, the more expensive it gets.

About Us

Woda Auto has been dominating the automotive industry for 25 years. Our extensive expertise in engine systems can help your cylinder head servicing initiative become a success. Contact us to know how our innovation and experience can aid your business.