When the cylinder head temperature sensor starts to act up, you’ll experience some symptoms. This sensor doesn’t fail often, but when it does, it can throw off the way your engine behaves. Before you jump to conclusions or replace it, it helps to know what can go wrong and how to test it.

What Is a Cylinder Head Temperature Sensor?

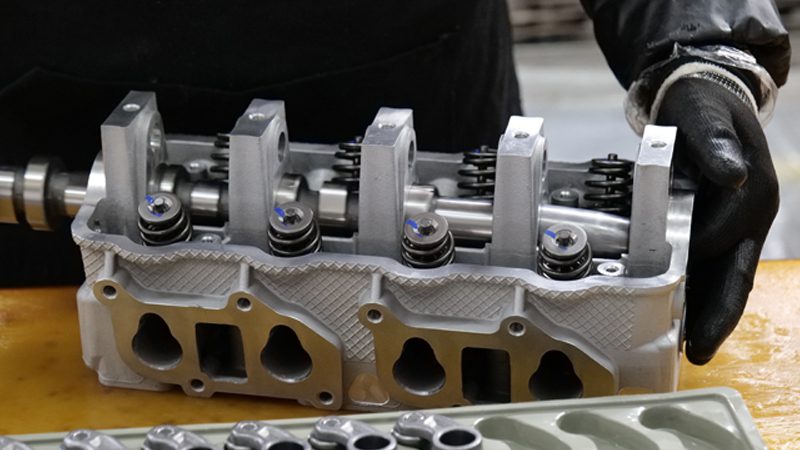

A cylinder head temperature sensor, or you may know it as a CHT sensor, sits on the cylinder head, which is the upper or side portion of the engine block in your car.

Its job is quite simple but important. It checks how hot the cylinder head gets during operation. That data goes straight to the ECU, which is the engine’s main control unit. It uses the numbers to adjust how the engine behaves so it doesn’t overheat or get damaged under load.

You’ll find this sensor in plenty of Ford engines, especially the Triton Modular and Voodoo flat-plane crank V8s. But it’s not something every car has. Many modern engines rely on the Engine Coolant Temperature (ECT) sensor instead, and a few come with both. As newer cylinder head designs came in, some manufacturers just moved away from needing a dedicated CHT sensor altogether.

The sensor works as a thermistor. It changes resistance based on how hot it gets, which gives a temperature reading from the cylinder head. That reading gets passed to the ECU or ECM to let it know how hot the cylinder head is running.

Once the ECU gets that data, it adjusts fuel injection timing, ignition timing, and cooling fan operation based on the temperature. These changes keep the engine within a safe temperature range under different driving conditions.

If the cylinder head temperature rises beyond normal levels, the sensor sends that warning to the ECU. This allows the control unit to take quick action, like turning on the fan, before the heat causes damage to the engine, like a blown head gasket. The sensor does an important job even though it’s small and often overlooked.

What Happens When the Cylinder Head Temperature Sensor Goes Bad?

If your car uses a CHT sensor and it starts to fail, these are the symptoms that show up:

- The first change is usually a drop in fuel economy per gallon. The reason is that the sensor feeds inaccurate data to the ECU, which throws off the fuel-to-air mixture. That imbalance means the engine runs rich or lean at the wrong time, and burns more fuel than needed.

- A faulty CHT sensor can also trigger the check engine light on your car and bring up a P1299 or P1289 error code when you scan it on a code reader tool, which points to a cylinder head over-temperature condition.

- Without the error code, you might still catch something off during a scan. For example, the CHT reading may fluctuate a lot on the scan tool, even when the engine isn’t doing much.

- Rough idling also kicks in, and in some cases, the engine might stall at low RPMs. These symptoms can show up on and off, especially during cold starts or stop-and-go traffic.

- It might take longer than usual to crank the engine, and when it finally starts, the car might go straight into limp mode.

- Power drops, and the engine refuses to rev the way it should. At first, the loss of performance might be easy to miss. But as the sensor continues to send wrong data to the ECU, those issues become more consistent and harder to ignore.

- Sometimes, the engine cranks like everything’s fine, but doesn’t fire at all. That usually means the sensor has completely lost its signal or is sending extreme values to the ECU.

- When the car fires up, it may shoot a bunch of smoke out the back, which is all the raw fuel that got dumped in when it was attempting to start.

How is Cylinder Head Temperature Measured?

The normal operating temperature for a car’s cylinder head usually falls between 195°F and 220°F (90°C to 105°C). This range allows the engine to operate within a safe temperature zone and prevents overheating under normal conditions.

For most NA engines, 200°F to 220°F is typical during regular driving. On track days or under heavy load, it can rise beyond that, and even 245°F to 250°F is considered normal if the ramps go down afterward. But if you regularly see high cylinder head temperatures on your scan tool, then there might be something wrong with the CHT sensor, and you need to replace it.

There are many scanners out there, OBD scanners as well, that can display live data streams of your car’s behavior, including coolant temperature, and some may also display CHT if the sensor is there.

In some vehicles, a cylinder head temperature sensor is used instead of or alongside the ECT sensor. Unlike the coolant sensor, the CHT sensor reads heat directly from the metal of the cylinder head. It does not rely on coolant contact, which means it still reports temperature correctly even when the cooling system is low or leaking.

However, there is a catch!

The key thing to note here is that if your car has no CHT sensor, the ECU estimates cylinder head temperature using readings from the ECT sensor, intake air temperature, and engine load. Then, it shows you the figure under the cylinder head temperature sensor readings in your OBD device. This could be confusing, as you may think there is one installed in your car.

How to Test a Cylinder Head Temperature Sensor with a Voltmeter

Before you swap the old CHT sensor with a new one, here is a nice little hack to further confirm your suspicions. You can test the sensor with a voltmeter:

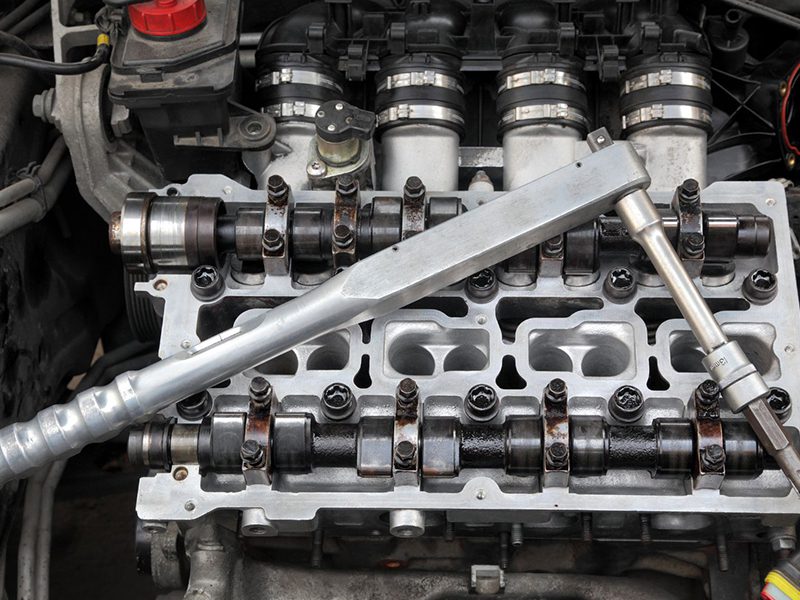

Step 1. Unplug the Sensor Connector Wire and Check Live Reading

First, pop the hood, find the connector wire for the CHT sensor under the intake manifold, and then disconnect it.

Once disconnected, plug in your scan tool and check the live data. With the sensor unplugged, the CHT voltage will jump to the full 5 volts since there’s no resistance pulling it down.

At the same time, you’ll notice the temperature reading drop to the default fail-safe value, which is around -40°F. The ECU should now show a fault under the CHT sensor status. You might also notice that the coolant temperature sensor reading drops to -40°F as well.

Step 2. Perform a Cold CHT Sensor Test

Next, grab the resistance chart for the CHT sensor from your car’s service manual. This chart lists the expected resistance values at specific voltages and temperatures. For example, if the live data originally showed 3.4 volts, cross-check that value on the chart. It should fall between the two cold end points shown in the service chart, and the resistance reading should fall within that range.

Now set your voltmeter to measure resistance (ohms). If you don’t have factory probes, use solid-core wire as makeshift leads. Insert them into the connector that goes directly to the CHT sensor.

Since the engine is cold during this test, your reading might show something like 43 kilo-ohms. Based on your vehicle’s service chart, if the temperature is around 60°F, that resistance falls in the correct range. This confirms that the sensor is accurate at this cold temperature.

Step 3. Confirm with a Hot CHT Sensor Test

To complete the test, start the engine and let it warm up. While the engine heats up, keep your voltmeter connected and observe the change in resistance. As the temperature goes up, the resistance should continue to drop.

If the readings stop matching what the values in your vehicle’s service chart show at every stage of the test, this eventually means that the sensor is no longer good. For that, you can perform other checks as well.

Step 4. Test PCM Side Sensor Connector

Before you decide to remove the intake manifold to reach the sensor to replace it, test the PCM side of the connector.

Use your meter to verify that one wire is receiving a proper 5-volt reference from the TPS. Then check the continuity and condition of the signal wire running to the ECU. Look for shorts to ground, shorts to power, open circuits, or any visible damage. If everything checks out but the sensor readings still fall out of range, that’s when you replace the sensor.

Note: In some cases, underlying damage such as a cracked cylinder head may also interfere with accurate readings.

Conclusion

So you now know what a cylinder head temperature sensor is, what signs it will show when it goes bad, and how you can confirm the replacement of a new sensor by testing it with a scan tool and a voltmeter.

About Us

Nanjing Woda Auto Technology Co., Ltd started in 1999, and since then, the company has been supplying engine systems, ignition systems, electrical systems, exhaust systems, suspension systems, steering systems, and other aftermarket products to businesses across the industry.

More than 100,000 products have been exported to over 100 countries, including Southeast Asia, the Middle East, Europe, Africa, North America, and South America. Our genuine quality and competitive pricing continue to earn trust from business clients worldwide.

A responsive sales team, dependable after-sales support, and long-standing cooperation with shipping partners help ensure on-time delivery. Contact us today for a strong partnership through consistent collaboration and mutual benefit.