The cylinder head is one of the most vital parts of any internal combustion engine. It seals the top of the combustion chamber, controls airflow, and supports critical components like valves, injectors, and spark plugs. But when you compare a diesel engine to a gasoline engine, the cylinder head design couldn’t be more different.

These differences aren’t just cosmetic — they’re rooted in how each engine burns fuel, handles pressure, and manages heat. For manufacturers, workshops, and engine parts suppliers, understanding these distinctions is key to choosing, designing, or servicing the right component.

In this guide, we’ll explain how diesel and gasoline cylinder heads differ in design, materials, and performance — and what these differences mean for your business and engine applications.

What Is a Cylinder Head?

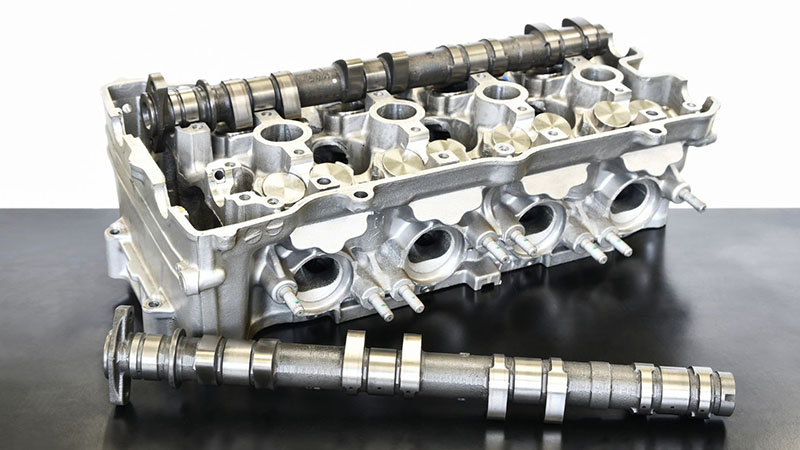

A cylinder head sits at the top of the engine block, closing off the cylinders and forming part of the combustion chamber. It has several critical functions:

- Seals compression between the block and the head via the head gasket.

- Directs air and exhaust flow through intake and exhaust ports.

- Houses vital components such as valves, injectors, spark plugs, and sometimes camshafts.

- Regulates heat through coolant and oil passages.

Because the head directly faces combustion pressure and heat, its material strength, cooling capacity, and precision machining are essential for engine reliability.

Combustion Differences

The biggest reason diesel and gasoline cylinder heads differ comes down to how combustion happens inside the engine.

| Aspect | Diesel Engine | Gasoline Engine |

|---|---|---|

| Combustion Type | Compression ignition | Spark ignition |

| Compression Ratio | 14:1 – 22:1 | 8:1 – 12:1 |

| Fuel Delivery | Direct injection into the combustion chamber | Port or direct injection mixed with air |

| Ignition Method | Auto-ignition by compression heat | Spark plug ignition |

Because diesel engines ignite fuel through compression rather than a spark, they must operate at much higher pressures and temperatures. That directly affects the cylinder head’s design and construction.

Diesel heads must withstand extreme compression forces — often more than 1,800 psi (over 120 bar) inside the combustion chamber. This requires thicker castings, stronger bolt structures, and reinforced valve bridges to prevent cracking or warping. Cooling passages also need to be larger to dissipate the intense heat around the injector area.

Gasoline engines, with lower compression ratios, can focus more on airflow efficiency and lightweight design. Their heads are thinner, lighter, and optimized for high-RPM performance.

Diesel vs Gasoline Cylinder Head Design Differences

1. Material and Strength

Diesel engines demand strength above all else. Most diesel heads are made from cast iron or reinforced aluminum alloy with iron inserts, built to handle the higher thermal and mechanical stresses of compression ignition.

The castings are thicker, and the head bolts are longer and stronger to resist distortion.

Gasoline engines usually use lightweight aluminum alloy heads to improve cooling and reduce overall vehicle weight. These designs don’t need the same level of mass or rigidity because combustion pressures are much lower.

Modern diesel manufacturers have begun adopting reinforced aluminum heads to save weight — but always with steel valve seats or cast iron inserts to handle the high pressure and prevent premature wear.

In short: Diesel heads are built for endurance, while gasoline heads are built for performance and efficiency.

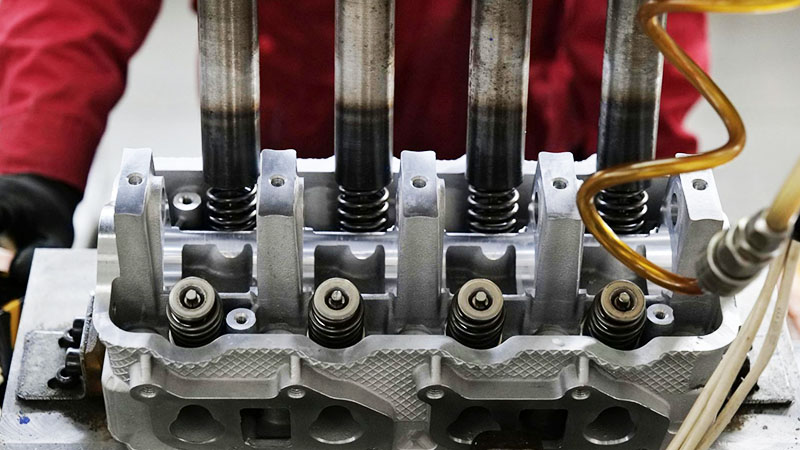

2. Combustion Chamber and Valve Layout

In diesel engines, combustion starts from fuel injected directly into highly compressed air inside the cylinder.

As a result, the combustion bowl is usually located in the piston crown rather than in the cylinder head. The head itself is generally flatter, containing injector ports and glow plug holes, but no spark plugs.

Gasoline engines, by contrast, form the combustion chamber inside the cylinder head itself. The head’s design encourages turbulence and efficient air-fuel mixing. Spark plugs are centered to ensure even ignition, while the valve layout is shaped for high-speed airflow.

This difference also means the fuel injector positioning and port geometry are completely distinct — one reason you can’t swap a diesel head for a gasoline one.

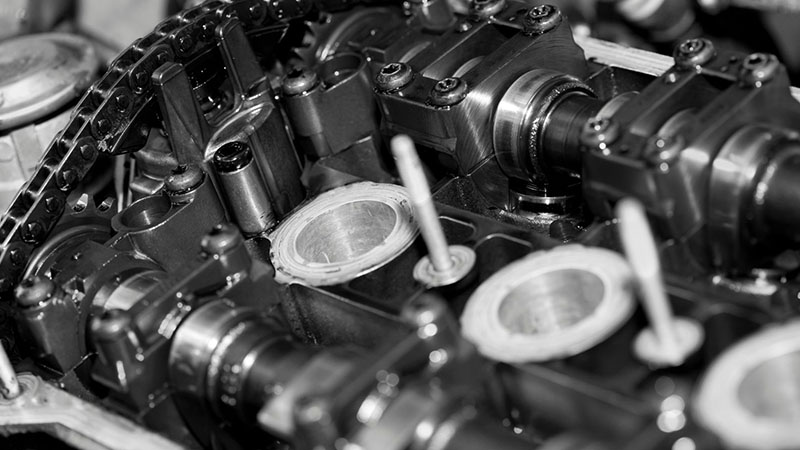

3. Cooling and Heat Management

Diesel combustion temperatures can exceed 2,000 °C (3,600 °F). To cope, diesel heads include:

- Larger and more complex coolant passages

- Thicker valve seats and bridges

- Reinforced areas around the injector ports

Gasoline engines run cooler overall but at higher speeds. Their heads use thinner walls and efficient coolant routing to manage heat quickly and maintain stable temperatures at high RPM.

The takeaway: diesel heads focus on heat endurance, gasoline heads on thermal efficiency.

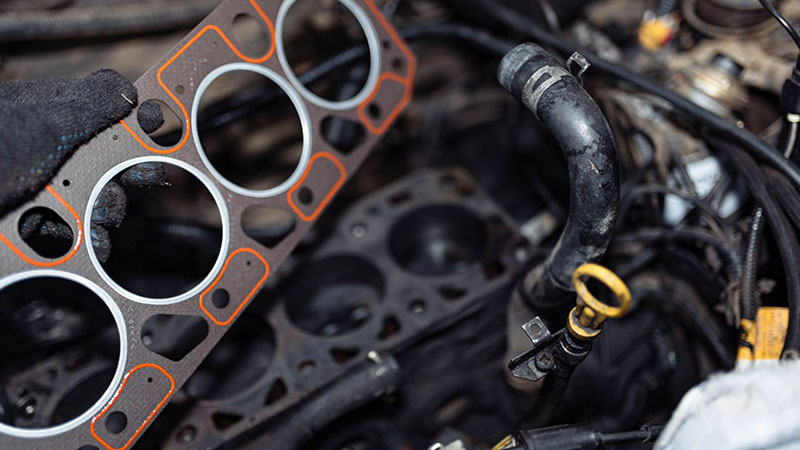

4. Compression and Gasket Design

Because diesel engines experience far higher internal pressure, their head gaskets must provide an extremely tight seal.

- Diesel gaskets: multi-layer steel (MLS) with reinforced fire rings to handle combustion forces.

- Gasoline gaskets: typically thinner MLS or composite gaskets suitable for lower compression.

Any slight warpage in a diesel cylinder head can lead to leakage or gasket failure, so these heads demand very tight machining tolerances and robust head bolts to maintain sealing integrity.

Performance and Application Differences

| Feature | Diesel Cylinder Head | Gasoline Cylinder Head |

|---|---|---|

| Power Output | High torque at low RPM | High horsepower at high RPM |

| Operating Pressure | Very high (up to 2,000 psi) | Moderate (800–1,200 psi) |

| Durability | Heavy-duty, long-life | Lighter duty, higher rev capability |

| Weight | Heavier | Lighter |

| Typical Use | Trucks, buses, industrial equipment | Passenger cars, light vehicles |

Diesel cylinder heads are designed for longevity under extreme load — making them ideal for trucks, construction machinery, and industrial engines that run for hours at a time.

Gasoline heads prioritize responsiveness and efficiency, better suited to cars that operate across a wider RPM range.

Can You Swap Diesel and Gasoline Cylinder Heads?

This is a common question — and the answer is a clear no.

Cylinder heads are engineered for their specific combustion process. A gasoline head lacks the structural strength, injector ports, and sealing design for diesel compression. A diesel head, on the other hand, has no provisions for spark plugs or the correct combustion chamber shape for gasoline ignition.

Even if the bolt pattern appeared similar, the mismatch in compression ratio, fuel system, and ignition method would cause the engine to fail almost instantly.

Always use a cylinder head designed for the exact engine type and model — never interchange diesel and gasoline heads.

Key Considerations When Choosing a Cylinder Head

For importers, distributors, and professional workshops, selecting the correct cylinder head is essential to ensure compatibility, performance, and long-term reliability. Even minor differences in design or machining can lead to serious fitment issues or premature failure. Here’s what to look for:

1. Confirm Engine Type and Code

Identify whether the engine is diesel or gasoline (e.g., Toyota 2L diesel, Nissan QR25 gasoline). Always match OEM numbers or casting references carefully before purchasing.

2. Material and Construction

- Diesel engines: Cast iron or reinforced aluminum heads with iron inserts for extra strength.

- Gasoline engines: Lightweight aluminum alloy optimized for cooling and efficiency.

3. Combustion Compatibility

- Diesel heads include injector and glow plug ports.

- Gasoline heads require spark plug ports and specific valve layouts for proper combustion.

4. Machining Quality

Inspect valve seats, guides, and gasket surfaces carefully. Diesel heads in particular demand precise resurfacing to prevent warpage and maintain sealing integrity.

5. Cooling Passages

Ensure coolant channels are clean and unobstructed — an overlooked detail that can significantly affect performance and longevity.

6. Supplier Reliability

Choose suppliers who maintain strict quality control, consistent pressure testing, and machining accuracy that meets or exceeds OEM standards.

FAQ

What’s the main difference between diesel and gasoline cylinder heads?

Diesel heads are stronger and thicker to handle higher compression pressures, while gasoline heads are lighter and designed for high-speed combustion.

Why are diesel cylinder heads heavier?

They need extra material and reinforcement to resist the intense forces of compression ignition.

Can you use a gasoline head on a diesel engine?

No — the combustion chamber design, port layout, and ignition system are completely incompatible.

What materials are used for diesel vs gasoline heads?

Diesel: cast iron or reinforced aluminum.

Gasoline: mainly aluminum alloy for light weight and fast heat transfer.

Which is more durable — a diesel or a gasoline cylinder head?

Diesel heads generally last longer under heavy-duty use, though they are more expensive and heavier.

Conclusion

While diesel and gasoline engines share the same basic goal — turning fuel into power — the way they do it is entirely different. That difference starts with the cylinder head.

Diesel heads are designed for strength, high compression, and long-term endurance. Gasoline heads are built for precision, lightness, and efficiency. Understanding these differences ensures that parts buyers, mechanics, and distributors choose the right component for the right engine.

At Woda Auto, we manufacture and supply high-quality cylinder heads built to OEM standards for both diesel and gasoline engines.

Whether you’re a distributor, importer, or workshop, we’re here to help you source reliable, precision-engineered components that keep your engines running stronger for longer.

Contact us today to request a quotation or explore our full product range.