If you’ve ever wondered how your car’s engine gets its fuel or why some engines deliver better fuel economy and performance, you’ve come to the right place.

Fuel injection, whether through indirect injection or direct injection, directly impacts combustion efficiency, engine power, and the overall reliability of the fuel delivery system.

In today’s blog, we’ll break down these fuel injection systems, compare their benefits and drawbacks, and highlight why many automakers, parts manufacturers, and industry professionals are increasingly favoring direct injection technology to meet today’s demands for efficiency and performance. Let’s get into it.

What is Direct Fuel Injection?

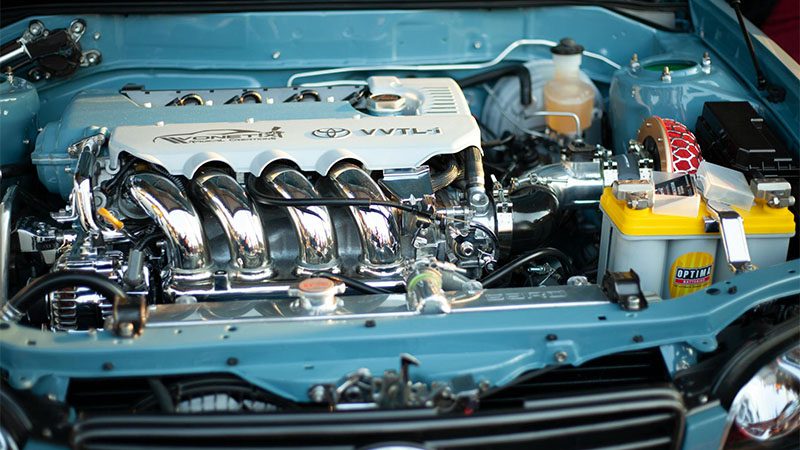

A direct injection system sends fuel directly from the tank into the engine’s combustion chamber due to high injection pressure, using precise fuel injectors controlled by the engine control unit (ECU).

Compared to more traditional port fuel injection systems, where the injector sprays fuel into the intake port, direct injection allows for better atomization and more accurate fuel delivery right where combustion occurs.

This, in turn, leads to better fuel efficiency, noticeably reduced fuel consumption, and noticeably improved engine performance.

When injecting fuel directly into the combustion chamber, direct fuel injection engines achieve higher combustion efficiency, which contributes to both more power and lower emissions. Be that as it may, the system’s complexity requires specialized maintenance and can lead to issues like carbon deposits on intake valves.

Despite these issues, direct fuel injection technology is rapidly gaining traction in the industry, especially in modern gas engines. If you want to know how fuel injectors compare to good old carburetors, click here!

How Does Direct Injection Work?

A direct fuel injection system relies on high-pressure fuel pumps that deliver fuel directly from the fuel tank and into the combustion chamber. These are physically being moved by fuel injectors, which are controlled via the ECU.

This means that, depending on how the driver operates the vehicle, the ECU calculates the perfect amount of fuel that needs to be delivered, depending on factors such as engine speed, load, temperature, or driving modes.

These systems can provide more power on demand while also being able to prioritize fuel economy. The fuel injection pressure changes depending on the situation, and thus, the system can offer a balanced approach to fuel delivery.

Direct Injection vs Indirect Injection – Head-to-Head Comparison

Now it’s time to compare direct injection vs indirect injection engines and see what makes them different. Here is a quick overview:

| Feature | Indirect Fuel Injection | Direct Fuel Injection |

|---|---|---|

| Fuel Delivery Location | Fuel is injected into the intake manifold | Fuel is injected directly into the combustion chamber |

| Fuel-Air Mixing | Fuel mixes with air before entering the chamber | Fuel mixes directly inside the combustion chamber |

| Control Precision | Less precise fuel-air mixture control | More precise control over the fuel-air mixture |

| Typical Use | Older IDI engines, some diesel, and gasoline | Modern gasoline DI engines, high-performance DI engines, fewer diesel engines |

| Combustion Efficiency | Moderate | Higher due to precise fuel delivery |

| Fuel Economy | Generally lower | Improved fuel economy and efficiency |

| Emissions | Higher emissions due to less precise control, especially on diesel engines | Lower emissions with optimized combustion |

Benefits and Advantages of Direct Injection Systems vs Indirect Injection Systems | Comparison

Here are the general pros and cons of direct injection systems:

Benefits of Direct Injection

- ✅ Improved fuel consumption and reduced fuel consumption

- ✅ Enhanced engine efficiency with better combustion control

- ✅ Increased power output and improved engine performance

- ✅ More responsive throttle and smoother idle

- ✅ Allows for higher compression ratios, boosting overall engine power

Drawbacks of Direct Injection

- ❌ More complex system requiring specialized training and equipment

- ❌ Higher maintenance costs due to high-pressure fuel system components

- ❌ Prone to carbon buildup on intake valves, leading to performance issues

- ❌ Fuel injectors can clog more easily, affecting fuel delivery

- ❌ Often requires the use of premium gasoline with higher octane ratings

Here are the general pros and cons of indirect injection systems:

Benefits of Indirect Injection

- ✅ Simpler and less complex system compared to direct injection

- ✅ Generally lower maintenance and repair costs

- ✅ Proven reliability with fewer specialized service requirements

- ✅ Less prone to carbon buildup on intake valves

- ✅ Compatible with a wider range of fuel qualities, including regular gasoline

Drawbacks of Indirect Injection

- ❌ Less precise fuel-air mixture control, leading to lower combustion efficiency

- ❌ Typically results in higher fuel consumption and reduced fuel economy

- ❌ Lower power output compared to direct injection GDI system engines

- ❌ Increased emissions due to less optimized combustion

- ❌ Less responsive throttle and rougher idle compared to direct injection

Are Direct Fuel Injection Systems Better than Indirect Fuel Injection Systems?

Ultimately, the answer to this question depends on what you or your business values more. On the one hand, direct injection engines offer improved fuel consumption, higher power, and more precise fuel control, but they also come with increased complexity, higher maintenance costs, and issues such as carbon buildup.

On the other hand, indirect injection systems are simpler, more reliable, and easier to maintain, but generally provide lower fuel economy and less performance. Choosing between them depends on your priorities.

Top 5 Most Important Direct Injection Engine Maintenance Tips

Here are the most important tips to keep in mind when maintaining a direct injection engine. Here is what to keep in mind:

- Regularly clean fuel injectors and the intake system to prevent carbon buildup.

- Use high-quality fuel with detergents and add fuel system cleaners periodically.

- Maintain spark plugs diligently, as they wear faster in high-pressure combustion environments.

- Schedule professional inspections since direct injection systems need specialized training and equipment for proper service.

- Address any signs of injector clogging or knocking early to avoid costly repairs. Regular cleaning is key.

There are also many other tips and tricks on how to maintain an engine, and here is where you’ll master them!

Most Common Direct and Indirect Injection Engine Issues

Many potential issues can plague direct and indirect injection engines, and here are the ones to keep in mind.

Common Issues in Direct Injection Engines

GDI System Carbon Buildup on Intake Valves

- Because fuel is injected into the combustion chamber directly, the intake valves don’t get washed by fuel, and this can lead to carbon deposits that reduce airflow and cause rough idling or output loss, especially on diesel engines.

Fuel Injector Clogging

- High-pressure fuel injectors in direct injection systems can get clogged by junk or deposits, which disrupt fuel delivery and cause misfires or reduced engine performance.

High-Pressure Fuel Pump Failure

- The complex high-pressure fuel pump needed for direct injection can wear out or fail, and thus cause fuel delivery issues, poor engine start, or stalling.

Common Issues in Indirect Injection Engines

Intake Valve Wear and Deposits on Gasoline Direct Injection IDI Engines

- Even though less prone to carbon problems, indirect injection engines can still suffer from deposits and wear on the intake valves, which affects the system’s efficiency over time.

Gasoline Engines Knocking or Pre-Ignition

- With less precise fuel-air control, indirect injection (di system) engines can experience knocking or even pre-ignition under certain conditions, which can damage the engine if not taken care of.

Lower Fuel Ratings Leading to Combustion Chamber Residue Buildup

- Less efficient combustion in indirect injection engines causes incomplete burning, leading to residue buildup in the chamber and the exhaust system.

GDI Engine and System Technology – What You Need to Know!

GDI engines, or gasoline direct injection engines, are a type of modern fuel delivery systems that use gasoline as the fuel source.

GDI engines use a high-pressure fuel rail and fuel injectors to deliver fuel directly into the combustion chamber.

These are designed to provide precise control over fuel injection and engine performance, and that is one of the main reasons why GDI engines are becoming increasingly popular in the industry, slowly phasing out indirect (IDI) engines entirely.

Future of Direct Injection Engines and Air Cell Technology

As the automotive world keeps on progressing, direct injection engines are expected to play a major role in the years ahead. Automakers are testing various kinds of technologies to further boost the pros associated with GDI engines while lowering the overall drawbacks.

These advances in technology, such as the use of turbocharging, advanced air cell technology, sophisticated spark plugs, and supercharging, will continue to improve the efficiency and performance of direct injection engines and make them a superior product to IDI engines in pretty much every way besides complexity.

Greater efficiency, lesser heat loss, fewer disadvantages in terms of grunt, high rpms, fewer reliability problems, DI systems, and DI engines will continue to use less fuel, achieve higher fuel efficiency, and will be the backbone of the future engine car technology.

We also need to mention that the use of alternative fuels, such as biofuels, hybrid engines, and hydrogen, may also become more prevalent in direct injection engines.

All in all, direct injection engines will continue to be a key component of the automotive industry, while efforts to improve fuel efficiency and reduce emissions are what most automakers want.

Conclusion

Both direct fuel injection and indirect fuel injection have their pros and cons, and knowing which you or your business deems vital is key to deciding the better option.

Either way, it’s safe to say that most people and businesses around the world will prefer direct fuel injection engines simply because they are more advanced, are mounted on modern-day cars, and are likely to give you a more pleasant driving experience.

Direct-injected engines have progressed quite a lot in the past few years, and all of the piston crown, air cell, port injection, cylinder walls, and cylinder head problems have been mostly ironed out. With that in mind, direct-injected engines win.

Looking to Upgrade Your Fleet with Advanced Direct Injection Engines and Reliable Components?

With years of expertise in the automotive industry, Nanjing Woda Auto Technology Co., Ltd. delivers high-quality engines and parts optimized for modern fuel injection systems. Whether you need engines featuring spray-guided technology or components designed for efficient fuel spray into the main combustion chamber, WODA has you covered on all fronts!

Our products minimize heat loss and improve combustion efficiency by precisely spraying fuel directly into the cylinder head and pre-combustion chamber—perfect for businesses focused on performance and fuel economy at the same time!

If you run a parts warehouse, repair shop, or import/export operation, WODA offers:

✅ Scalable inventory of cutting-edge direct injection engines and engine components

✅ Competitive B2B pricing with reliable global shipping

✅ Technical support specializing in advanced injection systems and spray-guided technology

✅ Replacement parts engineered to resolve common issues like carbon buildup, injector clogging, and combustion inefficiencies

Serving customers in over 100 countries, WODA’s trusted components help you deliver, time and time again! Contact us today to reinvent your business with the latest in engine technology!