Fuel injection technology plays a critical role in modern engine performance, efficiency, and reliability. Among the most common systems used today are Direct Injection (DI) and Port Fuel Injection (PFI), often referred to under the broader term Electronic Fuel Injection (EFI).

Although both systems serve the same basic purpose — delivering fuel into the engine — they work in very different ways and come with distinct advantages and trade-offs. These two systems are commonly compared in terms of fuel efficiency, performance, reliability, maintenance cost, and long-term operating conditions.

In this guide, we’ll break down how each system works, compare their real-world performance, and help you understand which fuel injection system makes more sense depending on your application and market.

What Is Direct Injection?

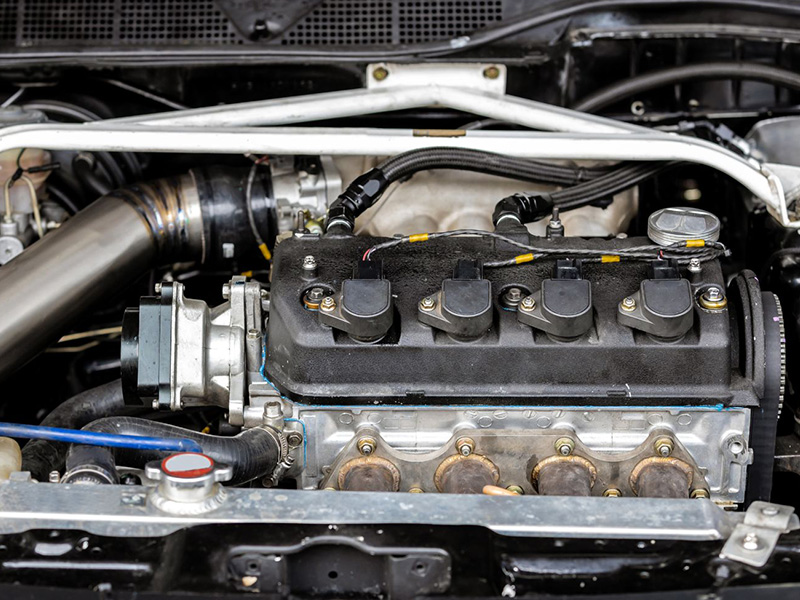

Direct Injection (DI), also known as Gasoline Direct Injection (GDI), is a fuel delivery system where fuel is injected directly into the combustion chamber of the engine.

Instead of mixing fuel with air in the intake system, DI sprays fuel straight into the cylinder, just before or during the combustion process.

How Direct Injection Works

In a DI system:

- Fuel is delivered by a high-pressure fuel pump.

- Injectors operate at extremely high pressure (often 100–350 bar for gasoline engines).

- Fuel is sprayed directly into the cylinder.

- Air and fuel mix inside the combustion chamber itself.

This allows the engine to control fuel delivery with much higher precision, especially under varying loads and speeds.

What Is Port Fuel Injection (PFI / EFI)?

Port Fuel Injection (PFI) is a type of Electronic Fuel Injection (EFI) system where fuel is injected into the intake port, just before the intake valve.

PFI is also commonly called:

- Multi-Point Injection (MPI)

- MPFI

- Port Injection

In this system, fuel mixes with air before entering the combustion chamber.

How Port Fuel Injection Works

In a PFI system:

- Fuel injectors are mounted in the intake manifold.

- Fuel is sprayed into the intake port.

- Air and fuel mix as they flow past the intake valve.

- The mixture then enters the cylinder for combustion.

PFI systems operate at much lower pressure compared to direct injection and have been widely used for decades.

Direct Injection vs Port Fuel Injection: Key Differences

Here’s a practical comparison of the two systems:

| Feature | Direct Injection (GDI) | Port Fuel Injection (PFI) |

|---|---|---|

| Injector location | Inside combustion chamber | In intake port |

| Fuel pressure | Very high | Moderate |

| Power output | Higher | Moderate |

| Fuel efficiency | Higher | Lower |

| Carbon buildup risk | High | Very low |

| Maintenance cost | Higher | Lower |

| Fuel quality sensitivity | High | Low |

| System complexity | High | Lower |

This table alone explains why both systems still exist in modern engines.

Advantages of Direct Injection

Direct injection became popular mainly because of its performance and efficiency benefits.

1. Higher Fuel Efficiency

By injecting fuel directly into the cylinder, the engine can:

- Use leaner air-fuel mixtures.

- Reduce fuel waste.

- Improve combustion control.

This typically results in better fuel economy, especially in city driving.

2. Increased Power Output

DI engines can operate at higher compression ratios without knocking, which leads to:

- More power from the same displacement.

- Better throttle response.

- Improved torque at low RPM.

3. Lower Emissions (In Theory)

More precise fuel control allows for cleaner combustion under controlled conditions, helping manufacturers meet modern emission standards.

Disadvantages of Direct Injection

Despite its advantages, direct injection introduces several real-world challenges.

1. Carbon Buildup on Intake Valves

This is the most well-known issue with GDI engines.

Because fuel is injected directly into the cylinder, intake valves no longer receive fuel spray, which previously helped clean them. Over time, oil vapors and contaminants accumulate, forming carbon deposits.

This can lead to:

- Rough idle

- Power loss

- Misfires

- Reduced efficiency

2. Higher System Cost

Direct injection systems require:

- High-pressure fuel pumps

- Precision injectors

- More complex ECU control

All of these increase:

- Manufacturing cost

- Replacement cost

- Repair complexity

3. Sensitive to Fuel Quality

Poor fuel quality can cause:

- Injector clogging

- Pump wear

- Combustion instability

This makes GDI less tolerant in regions where fuel standards vary.

Advantages of Port Fuel Injection

PFI may be older technology, but it remains popular for good reasons.

1. Better Long-Term Reliability

PFI systems are:

- Simpler in design

- Less sensitive to contamination

- Easier to diagnose and repair

They typically last longer with fewer expensive failures.

2. Natural Intake Valve Cleaning

Because fuel passes over the intake valves, it helps dissolve oil residues and carbon, preventing buildup.

This results in:

- Cleaner intake system

- More stable performance over time

3. Lower Maintenance Cost

PFI components are:

- Cheaper

- Widely available

- Easier to service

This is especially important for fleets, workshops, and developing markets.

Is Direct Injection More Reliable Than EFI?

Short answer: not necessarily.

Direct injection engines can be very reliable under the right conditions. When fuel quality is high, maintenance is performed on schedule, and operating conditions are stable, GDI systems can deliver strong performance with relatively few issues. In markets with good fuel standards and professional service networks, many direct injection engines run smoothly for years.

However, long-term reliability is often more complex.

Many GDI engines are known to experience:

Carbon buildup on intake valves.

Because fuel no longer washes over the intake valves, oil vapors can accumulate and form carbon deposits, leading to rough idle, power loss, misfires, and reduced efficiency.

Injector problems.

Direct injectors operate under extremely high pressure and tight tolerances, making them more sensitive to poor fuel quality and contamination.

High-pressure fuel pump wear.

This component works under heavy load and is costly to replace when it fails.

In contrast, Port Fuel Injection systems are mechanically simpler and more forgiving. Lower operating pressure and continuous fuel washing of intake valves make PFI engines less sensitive to fuel quality and maintenance conditions.

As a result, PFI systems often prove more durable and predictable over long-term real-world use, especially in cost-sensitive or developing markets.

Does Direct Injection Cause Carbon Buildup?

Yes — this is a well-known and widely documented issue with direct injection engines.

In Port Fuel Injection (PFI) systems, fuel is sprayed into the intake port and flows past the intake valves, creating a natural cleaning effect that helps prevent heavy deposits.

In Gasoline Direct Injection (GDI) systems, fuel is injected directly into the combustion chamber, so the intake valves no longer receive any fuel spray and lose this self-cleaning function.

Over time:

- Oil mist from the crankcase ventilation and EGR system sticks to the hot intake valves.

- These residues gradually form hard carbon deposits.

- As the deposits build up, airflow into the engine becomes restricted.

This can lead to rough idle, power loss, reduced fuel efficiency, and misfires.

The most common solution is walnut blasting, a mechanical cleaning process that removes carbon deposits from the intake valves. While effective, it requires partial disassembly and adds extra maintenance cost and downtime over the engine’s lifespan.

Which Is Better for Developing Markets?

This is where the answer becomes more practical than theoretical.

In many regions such as Africa, Latin America, the Middle East, and parts of Southeast Asia, real-world conditions differ significantly from developed markets. Fuel quality often varies, repair infrastructure can be limited, and access to specialized diagnostic tools or trained technicians is not always guaranteed.

At the same time, cost sensitivity is high, and buyers tend to prioritize total ownership cost over peak performance or the latest technology. For commercial vehicles and aftermarket engines, long-term durability and ease of maintenance usually matter more than small gains in efficiency or power.

Under these conditions, Port Fuel Injection (PFI) often makes more business sense. Its simpler design, lower operating pressure, and widely available parts make it easier and cheaper to maintain. PFI systems are also more tolerant of inconsistent fuel quality and less likely to suffer from expensive component failures.

For many developing markets, the key priorities are reliability, serviceability, and predictable operating costs — areas where PFI systems continue to offer clear practical advantages.

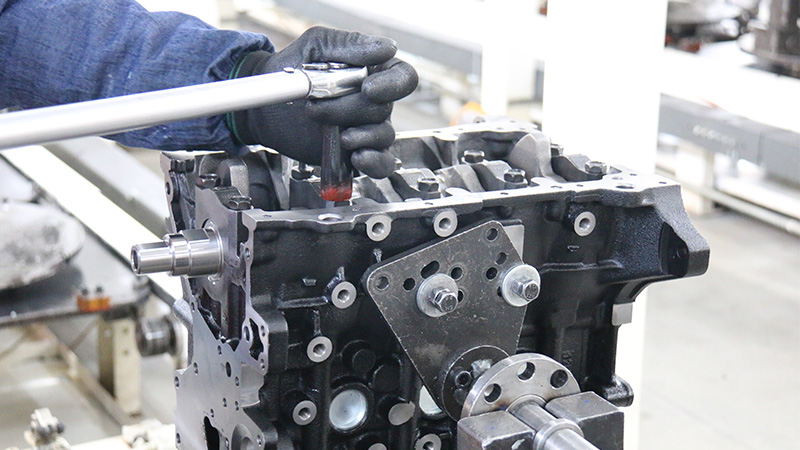

From a Manufacturer’s Perspective

From an engine manufacturing standpoint, the two systems have very different implications in terms of cost, complexity, and long-term risk.

Direct Injection systems rely on more advanced and expensive components, such as high-pressure fuel pumps, precision injectors, and more complex electronic control units. The assembly process requires tighter tolerances and stricter quality control, which increases production cost.

In addition, GDI systems often carry a higher warranty and after-sales risk, as issues like injector failures, pump wear, and carbon buildup can lead to more service demands over time.

Port Fuel Injection systems, in contrast, are simpler and more standardized. Component costs are lower, assembly is less complex, and the supply chain is easier to manage. Parts are widely available, aftermarket support is more straightforward, and long-term reliability tends to be more stable.

For many B2B-focused engine suppliers, especially those serving commercial or emerging markets, PFI remains the more practical and commercially viable option, offering a better balance between production efficiency, reliability, and total lifecycle cost.

Which Fuel Injection System Should You Choose?

There is no universal “best” system — only the best system for your specific application and operating conditions.

Choose Direct Injection if:

- You prioritize performance and fuel efficiency.

- You operate in markets with high-quality fuel and strong service support.

- You accept higher system complexity and maintenance costs in exchange for better performance and emissions control.

- Your focus is on passenger vehicles or premium applications where technology is a key selling point.

Choose Port Fuel Injection if:

- You value reliability, simplicity, and long-term durability.

- You serve cost-sensitive or developing markets.

- You need easy maintenance, widely available parts, and predictable operating costs.

- Your engines are used in commercial or fleet applications where uptime matters more than marginal efficiency gains.

Many modern engines now use dual injection systems, combining both DI and PFI to balance performance, efficiency, and long-term reliability.

FAQ

Is direct injection better than port injection?

Direct injection offers better performance and efficiency, but also introduces higher cost and maintenance complexity.

Is port fuel injection outdated?

No. PFI is still widely used and remains highly relevant for many commercial and aftermarket applications.

Is GDI more expensive to maintain?

Yes. High-pressure components and carbon buildup issues typically increase long-term maintenance costs.

Can direct injection be repaired easily?

It depends. Repairs often require specialized tools and expertise.

Which system lasts longer?

In most real-world conditions, PFI systems tend to be more durable over long service life.

Conclusion

Direct injection represents modern engine technology focused on performance and efficiency, while port fuel injection reflects proven engineering focused on reliability and simplicity. Neither system is objectively superior in all situations.

The right choice depends on:

- Market conditions

- Fuel quality

- Maintenance capability

- Cost structure

- Long-term business priorities

Understanding these trade-offs is far more important than simply choosing the most advanced technology on paper. In many real-world scenarios, especially in commercial and emerging markets, simpler systems often deliver better long-term results.

About Us

Woda Auto is a professional automotive engine and engine components manufacturer with over 25 years of industry experience. We specialize in supplying complete engines, cylinder heads, crankshafts, and core engine parts to B2B customers worldwide, including distributors, workshops, and fleet operators across Latin America, Africa, and the Middle East.

Contact us today to discuss your engine requirements and explore suitable solutions for your specific market needs.