If you’ve ever browsed engine specs or shopped for auto parts, you’ve likely come across terms like DOHC, SOHC, and OHV. But what do they actually mean—and why do they matter?

In this guide, we’ll break down these common internal combustion engine types, compare how they work, and explain which setups are best suited for different vehicles and performance needs.

What Is an OHV Engine?

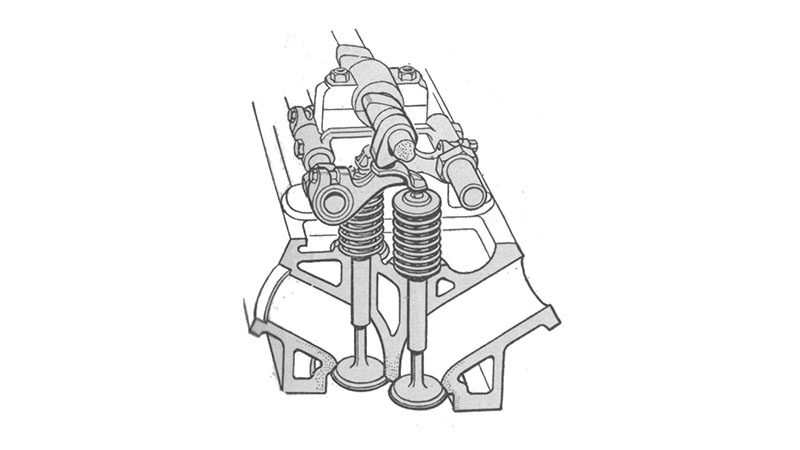

An OHV (Overhead Valve) engine—often called a pushrod engine—features a camshaft located inside the engine block, beneath the cylinder head. This layout uses pushrods and rocker arms to open and close the valves, making it a mechanically simpler system compared to modern overhead camshaft designs.

Why It’s Still Used Today:

- Lower manufacturing cost makes it ideal for budget-conscious builds

- Strong low-end torque delivers great pulling power, especially at low RPMs

- Compact, straightforward design suits V8s and heavy-duty applications

- Less capable at high RPMs due to the added weight and complexity of the valvetrain

Where you’ll find them: OHV engines remain popular in full-size trucks, SUVs, and performance classics like the Chevrolet Corvette and Dodge Challenger SRT—where torque and ruggedness matter more than high-rev horsepower.

What Is an OHC Engine?

An OHC (Overhead Camshaft) engine places the camshaft directly in the cylinder head, above the combustion chamber. This modern layout eliminates the need for pushrods, reducing the number of moving parts between the camshaft and the valves.

Why It Outperforms OHV Designs:

- A lighter valvetrain allows the engine to rev higher with less strain

- Improved airflow and combustion lead to better overall efficiency

- Typically results in greater fuel economy compared to older OHV setups

OHC engines have become the standard in most modern vehicles due to their efficiency, cleaner emissions, and higher performance potential.

Types of Overhead Cam Configurations

SOHC (Single Overhead Camshaft):

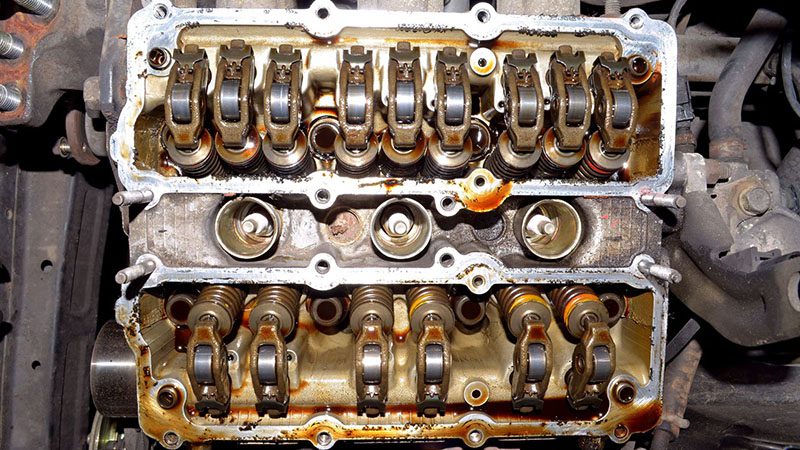

A SOHC engine uses one camshaft per cylinder bank to operate both the intake and exhaust valves.

This setup is mechanically simpler and often more compact than dual camshaft systems, making it cost-effective and easier to maintain.

However, the design offers limited flexibility in valve timing and layout, which can restrict airflow and reduce peak performance at higher RPMs.

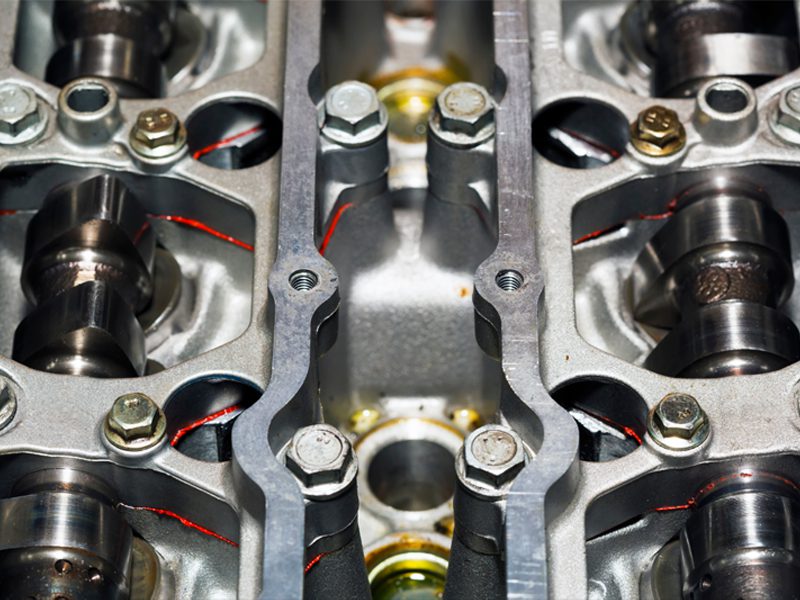

DOHC (Dual Overhead Camshaft):

A DOHC engine employs two camshafts per cylinder bank—one controlling the intake valves and the other managing the exhaust valves.

This configuration typically supports four valves per cylinder, which improves airflow and enhances combustion efficiency. It also enables more accurate positioning of both the valves and the spark plugs.

While DOHC engines are more complex and expensive to produce, they offer greater performance potential and are widely used in modern high-efficiency vehicles.

DOHC vs. SOHC vs. OHV: Key Comparisons

| Feature | OHV | SOHC | DOHC |

|---|---|---|---|

| Camshaft | Location Inside block | One in cylinder head | Two in cylinder head |

| Valve Actuation | Pushrods | Rocker arms or lifters | Direct via lifters |

| Performance Focus | Torque at low RPMs | Balanced performance | High-end horsepower |

| Complexity & Cost | Low | Moderate | High |

| Maintenance | Easy | Moderate | More involved |

| Common Use | Trucks, classic V8s | Older compact cars | Modern engines (4-cyl, V6, V8) |

Why DOHC Engines Are Everywhere Now

DOHC engines have become the standard in modern automotive engineering—and for good reason.

Their design supports higher engine speeds and increased power output, making them ideal for today’s performance demands.

They also integrate more effectively with technologies like variable valve timing (VVT), which helps optimize fuel efficiency and reduce emissions.

Thanks to improved airflow and combustion, DOHC engines deliver the right balance of power, efficiency, and environmental compliance that modern vehicles require.

Camshaft Design and Timing Systems: What They Mean for Modern Engines

The camshaft governs valve timing, directly impacting engine performance.

As the engine runs, the camshaft ensures that the air-fuel mixture enters the combustion chamber at the right moment and that exhaust gases are expelled efficiently.

This precise valve timing is essential for smooth operation, responsive power delivery, and overall fuel efficiency. A well-designed camshaft system can significantly enhance both horsepower and torque.

In SOHC and DOHC engines, the camshaft is driven by either a timing belt or a timing chain, both of which are connected to the crankshaft.

Timing belts are lightweight, quiet, and typically made from rubber reinforced with Kevlar. However, they require routine replacement—usually every 60,000 to 100,000 miles—and a failure in an interference engine can lead to serious internal damage.

Timing chains, made from durable metal, are more common in modern engines. They tend to last longer and need less frequent maintenance, though they rely on proper lubrication and can be slightly noisier.

Vehicle Applications and Industry Trends

DOHC engines are now widely adopted across a broad range of vehicles, not just for performance. They’re used in everything from compact commuter cars to SUVs and hybrid systems, offering automakers greater flexibility in engine design and tuning.

While performance and turbocharged vehicles benefit most from DOHC’s airflow efficiency and high-RPM potential, mainstream brands like Toyota, Honda, Ford, and GM also use DOHC setups extensively in their daily drivers. This reflects an industry-wide shift toward engines that balance power, efficiency, and emissions compliance across all segments—not just sports cars.

Looking Ahead: The Future of Engine Design

As automotive engineering continues to evolve, future engine designs will place an even greater emphasis on efficiency, precision, and adaptability.

We can expect to see more sophisticated variable valve timing systems, along with the use of lighter valvetrain materials to reduce mechanical inertia and improve responsiveness.

DOHC configurations will likely become even more widespread, especially in hybrid and turbocharged engines, where fine-tuned valve control is essential. Overall, the industry is moving toward a smarter balance between performance, fuel economy, and emissions compliance.

Frequently Asked Questions (FAQ)

Does “dual overhead cam” mean the engine has only two camshafts?

Not exactly. In a DOHC setup, each cylinder bank has two camshafts—so a V-type engine can feature as many as four camshafts. This setup improves valve control, allowing more power, higher torque, and better performance at higher speeds.

What are the advantages of DOHC over SOHC?

A DOHC engine offers more accurate valve actuation, supports as many valves as needed (typically four per cylinder), and delivers more horsepower and better torque at high RPMs. A SOHC engine, while simpler and cheaper, often uses two valves per cylinder, which limits airflow and performance.

Do smaller engine displacements benefit from DOHC setups?

Yes, smaller engine displacement engines often use DOHC configurations to compensate for size by improving airflow and combustion efficiency. This allows them to deliver higher performance without increasing engine size.

Conclusion

Whether you’re buying parts, tuning engines, or simply learning more about automotive tech, understanding the difference between OHV, SOHC, and DOHC engines gives you a valuable advantage.

Each configuration offers unique benefits: OHV engines shine in low-end torque and simplicity, SOHC offers a balance between performance and cost, and DOHC leads in high-rev horsepower and modern efficiency.

As engine design continues to evolve, DOHC remains the go-to setup for most manufacturers, thanks to its superior breathing capacity, compatibility with variable valve timing, and support for higher performance demands.

About Us

At Nanjing Woda Auto Technology Co., Ltd., we specialize in supplying high-quality engine components—including camshafts, cylinder heads, and complete engine assemblies—to customers around the world.

With 25 years of experience in the automotive parts industry, we’re a trusted partner for workshops, distributors, and retailers seeking durable, precision-engineered parts.

Explore our catalog or contact us today to find out how we can support your business with reliable engine solutions.