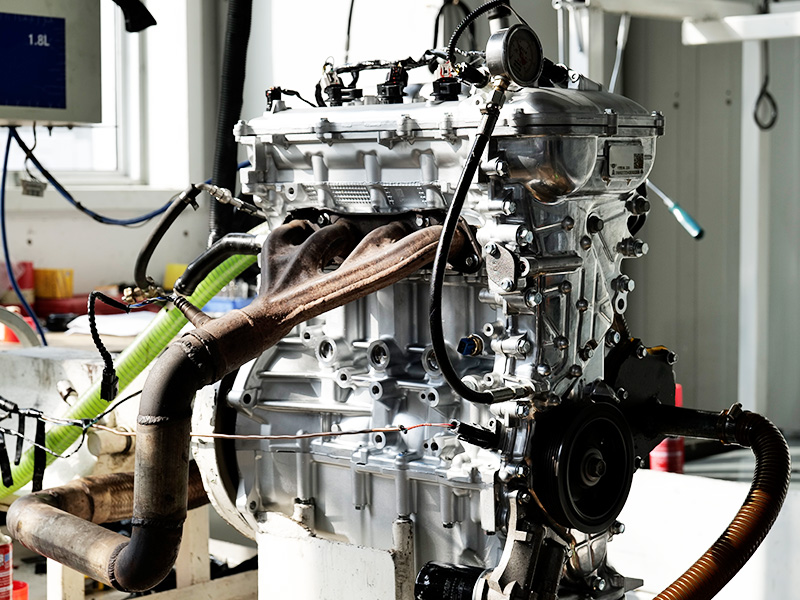

In engine manufacturing, ensuring each unit meets quality and performance expectations before shipment is critical. Two fundamental tests play central roles in the final inspection process: the cold test and the hot test.

Although both aim to verify engine quality, they do so in very different ways. Understanding these differences helps manufacturers optimize production testing, catch defects early, and maintain consistent reliability.

What Are Production Engine Tests in Manufacturing?

Before we dive into cold and hot tests specifically, it’s worth noting that engine testing at the end of the production line is about verifying assembly integrity and performance.

OEMs and tier-one manufacturers leverage specialized test systems — often integrated with digital data collection and analysis tools — to ensure each engine meets design specifications and will function correctly under real-world conditions once installed in a vehicle or machine.

What Is an Engine Cold Test?

How a Cold Test Works

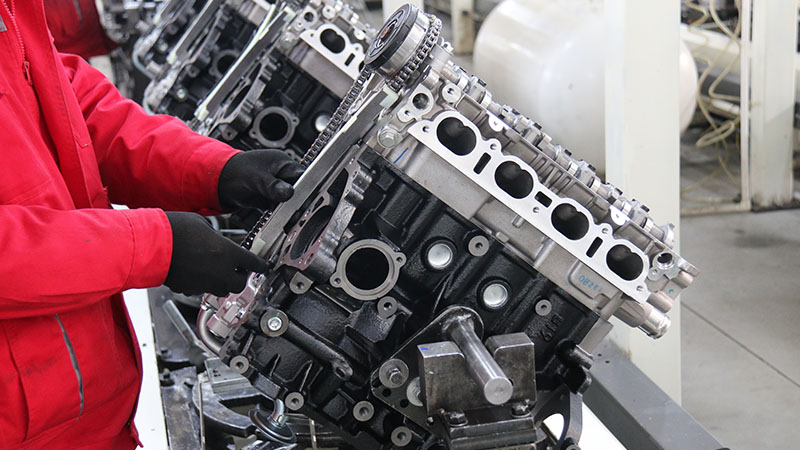

A cold test is a production test conducted without firing the engine. In this process, an external electric motor or similar device rotates the engine’s crankshaft while the engine remains “cold,” meaning no combustion takes place. As the engine is driven mechanically, sensors collect data on its mechanical response and internal conditions.

This type of testing focuses on verifying that the engine has been assembled correctly. It helps identify issues such as improper timing, external leaks (fuel, oil, air, or coolant), and abnormal resistance in components that should move smoothly even without combustion.

Advantages of Cold Testing

One of the main advantages of cold testing is its ability to detect assembly defects early in the production line. Since the engine does not run under its own power, cold testing requires no fuel and produces no exhaust emissions, making it an efficient and environmentally friendly option for large-scale production.

Cold tests are also well suited for automation and high throughput. By combining fast cycle times with detailed data analysis — such as monitoring torque variation, crankshaft angle, and pressure changes — manufacturers can maintain consistent quality control while keeping testing costs relatively low.

What Is an Engine Hot Test?

How a Hot Test Works

Unlike a cold test, a hot test involves starting the engine and allowing it to run under controlled conditions that closely replicate real-world operation. During this process, the engine runs under its own power, burns fuel, and gradually reaches its normal operating temperature.

As the engine operates, engineers observe its behavior under combustion and monitor key performance parameters such as oil pressure, engine speed stability, torque output, fuel delivery, and noise, vibration, and harshness (NVH) characteristics.

Hot testing typically includes both idle and loaded conditions to evaluate engine performance across different operating states.

Why Hot Testing Is Used in Engine Manufacturing

The primary purpose of a hot test is to verify that the engine not only functions mechanically but also performs reliably under real thermal and dynamic conditions.

Hot testing is especially effective at identifying issues that may not appear during cold testing, such as thermal distortion, combustion irregularities, sealing problems, or performance degradation under load.

Because hot testing involves fuel combustion, it requires proper exhaust handling, ventilation, and safety controls. These additional requirements make hot tests more resource-intensive than cold tests.

However, for engines used in demanding applications or where performance assurance is critical, hot testing remains an essential part of the manufacturing and quality verification process.

Cold Test vs Hot Test: Side-by-Side Comparison

To clearly see how these testing methods differ:

| Aspect | Cold Test | Hot Test |

|---|---|---|

| Engine Running Under Its Own Power | ❌ No – engine is driven by an external motor | ✔ Yes – engine runs under combustion |

| Primary Purpose | Assembly verification and mechanical integrity check | Performance validation under real operating conditions |

| Detectable Issues | Assembly defects, improper timing, abnormal friction, external leaks (oil, fuel, air, coolant) | Combustion behavior, thermal distortion, power output issues, NVH, sealing under heat and load |

| Fuel Consumption | ❌ None | ✔ Required |

| Emissions Generated | ❌ None | ✔ Exhaust emissions present |

| Infrastructure Requirements | Lower – electric drive system, sensors, data acquisition | Higher – fuel supply, exhaust handling, ventilation, cooling, safety systems |

| Test Environment Complexity | Relatively simple and clean | More complex and regulated |

| Cycle Time | Shorter, well suited for high-volume production | Longer due to warm-up, stabilization, and load testing |

| Environmental Impact | Minimal | Noticeable due to fuel use and emissions |

| Automation Potential | Very high | Moderate |

| Typical Use in Production | Early screening, end-of-line assembly validation | Final performance validation, sampling, or critical engine applications |

Cold tests are typically faster, cleaner, and easier to integrate into high-volume production lines, making them highly effective for early detection of mechanical and assembly-related issues. Because they do not involve combustion, cold tests reduce operational costs and environmental impact while still providing valuable diagnostic data.

Hot tests, on the other hand, deliver a more complete picture of real-world engine behavior. By running the engine under actual thermal and dynamic conditions, hot testing reveals performance characteristics and issues that cannot be detected during cold testing alone. This makes hot tests especially important for engines used in demanding applications or markets where long-term reliability and performance assurance are critical.

Where These Tests Fit in the Production Workflow

In many modern engine assembly plants, cold testing occurs first — right after the final assembly. This allows production teams to quickly verify that components have been installed correctly and that there are no glaring assembly defects that would prevent the engine from functioning.

Since cold tests do not involve combustion, they also reduce the complexity of the testing environment, allowing for high throughput and fewer safety concerns.

Once the basic functional integrity is confirmed via cold tests, hot tests are often used for deeper validation — especially in lower-volume, high-value, or performance-critical engine applications.

For engines where customer use involves high stress, stringent duty cycles, or critical reliability needs, hot tests help verify that the unit behaves as expected when running under real load conditions.

In some production strategies, cold testing alone may be sufficient for functional assurance, with hot testing applied selectively based on specific quality control standards or regulatory requirements. Other manufacturers choose to perform both tests on every engine to maximize confidence before shipping.

Why Both Testing Methods Matter

Neither test alone tells the whole story.

- Cold testing ensures that the engine’s mechanical assembly is sound and free from obvious defects. It catches issues that can be hard to diagnose once the engine is running, such as misalignments, improper torque on bolts, or seals that might leak even without thermal expansion.

- Hot testing proves that an engine not only starts and runs but also performs under conditions similar to real operating environments. It captures performance data over time and reveals issues related to thermal stress, combustion irregularities, and dynamic behavior.

Together, these methods form a comprehensive quality assurance strategy, helping manufacturers balance efficiency, cost, and reliability.

What This Means for B2B Buyers and Engine Distributors

For B2B customers, understanding the difference between cold testing and hot testing is more than a technical detail — it directly affects product consistency, risk control, and after-sales costs. Engines that have undergone proper production testing are less likely to experience early-stage failures, leaks, or performance issues once installed or resold.

If your business involves importing, distributing, or installing engines, it is important to clarify what type of testing is performed before shipment.

Cold testing provides confidence that the engine has been assembled correctly and meets baseline mechanical requirements, while hot testing offers additional assurance that the engine performs reliably under real operating conditions.

For high-value engines, demanding applications, or markets with limited after-sales support, choosing suppliers that conduct both cold and hot testing can significantly reduce warranty claims, installation issues, and customer complaints.

Even when hot testing is not required for every unit, understanding the manufacturer’s testing standards helps B2B buyers make better sourcing decisions and set accurate expectations with end customers.

FAQ

What is the difference between an engine cold test and a hot test?

A cold test checks mechanical assembly without running the engine under combustion, while a hot test runs the engine under its own power to verify real operating performance and thermal behavior.

Can cold testing replace hot testing in engine manufacturing?

Cold testing can replace hot testing for basic assembly and functional checks, but it cannot fully replace hot testing when combustion performance, thermal stress, or load behavior must be verified.

Why do manufacturers use both cold and hot tests?

Because each test detects different issues. Cold tests are effective for early assembly defect detection, while hot tests reveal performance and thermal issues that only appear during real engine operation.

Is hot testing required for every engine before shipment?

Not always. Some manufacturers hot test every engine, while others apply hot testing selectively based on engine type, application, production volume, or quality requirements.

Which test is more environmentally friendly: cold or hot testing?

Cold testing is more environmentally friendly because it does not use fuel or generate exhaust emissions, making it well suited for high-volume production.

Conclusion

In engine manufacturing, production testing is never a one-size-fits-all process. Cold testing provides a fast and cost-effective way to verify mechanical integrity and assembly quality early in the production line, while hot testing delivers critical insight into how an engine performs under real operating and thermal conditions.

When applied together, these methods form a balanced quality assurance strategy, ensuring engines are both properly assembled and capable of reliable performance in real-world applications.

By understanding the strengths and limitations of each testing approach, manufacturers and buyers can make more informed decisions—whether that means optimizing production workflows, reducing early failure rates, or sourcing engines with greater confidence.

About Us

Woda Auto is an experienced engine manufacturer and exporter specializing in automotive engines and engine components for global B2B customers, including distributors, importers, and professional repair networks. We place strong emphasis on production testing, quality control, and consistency, ensuring every engine meets practical performance and reliability expectations before shipment.

If you are sourcing engines for wholesale, distribution, or project-based applications and would like to learn more about Woda Auto’s production testing standards, available engine models, or export solutions, our team is ready to assist.

Contact us now to discuss your requirements and explore reliable engine solutions tailored to your market.