Engine knocking is one of the most concerning noises a vehicle owner or technician can hear. It often starts as a light metallic tap, then becomes a rhythmic knock under load or acceleration. In many cases, it signals abnormal combustion or progressive mechanical wear—and if ignored, the damage can escalate quickly.

This guide breaks down the causes, symptoms, diagnostic process, and repair solutions for engine knocking. The goal is to help you identify the type of knock you’re dealing with, understand its severity, and know when a repair or full engine replacement is the most cost-effective solution.

What Is Engine Knocking?

Engine knocking refers to an abnormal sound caused by irregular combustion or mechanical damage inside the engine. Instead of fuel burning smoothly at the precise moment it should, pressure spikes or loose components create a metallic knocking, pinging, or tapping sound.

In general, engine knocks fall into two categories:

- Combustion knock (detonation, pre-ignition, low-octane fuel, carbon buildup)

- Mechanical knock (bearing wear, piston slap, rod knock, worn components)

Distinguishing between the two early helps prevent further damage.

What Does Engine Knocking Sound Like?

While descriptions vary, knocking usually resembles:

- A metallic “ping” under acceleration

- A deep rhythmic knock from the engine block

- A tapping sound during cold start

- A rapid metallic rattle when the engine is under load

If the noise increases with RPM, the source is likely mechanical. If it appears only during acceleration or load, it often relates to combustion.

Common Symptoms of Engine Knocking

- Metallic knocking or pinging during acceleration

- Loss of power or hesitation

- Poor fuel economy

- Engine vibration

- Overheating or elevated operating temperatures

- Check Engine Light (often misfire or knock sensor codes)

- Oil pressure warning (mechanical wear)

These symptoms often appear gradually rather than suddenly.

Main Causes of Engine Knocking

Engine knocking is not caused by a single issue. Below are the most common causes, explained in technical detail.

1. Low-Quality Fuel or Incorrect Octane Rating

If the fuel has a lower octane than the engine requires, the air-fuel mixture may ignite prematurely. This uncontrolled burn leads to detonation, creating sharp pressure spikes and a characteristic pinging sound.

Typical signs:

- Pinging under load

- Noise disappears after refueling with higher-octane fuel

2. Carbon Deposits on Pistons and Combustion Chamber

Carbon buildup reduces combustion chamber volume and increases compression, making the engine more prone to knock. Deposits can also retain heat, raising the risk of pre-ignition.

Contributing factors:

- Short trips

- Poor fuel quality

- Worn injectors

3. Incorrect Ignition Timing

If ignition timing is too advanced, the spark plug fires before the piston reaches top dead center. This causes the fuel mixture to “fight” the upward-moving piston, producing a knock.

Possible causes:

- Faulty crankshaft position sensor

- Timing chain stretch

- ECU calibration issues

4. Worn Connecting Rod Bearings (Rod Knock)

Rod knock is one of the most serious mechanical failures. When the bearing clearance becomes excessive, the connecting rod begins to move violently on the crankshaft journal.

Symptoms:

- Deep knocking sound

- Noise increases with RPM

- Low oil pressure

If untreated, it can lead to a thrown rod or complete engine seizure.

5. Low Engine Oil Level or Oil Pressure

Insufficient lubrication causes metal-to-metal contact between moving parts. Components such as rod bearings, wrist pins, and camshaft bearings can wear rapidly.

Diagnostics:

- Oil level inspection

- Oil pressure test

- Check for oil pump wear or blockages

6. Faulty Spark Plugs or Ignition Coils

Weak spark or misfires leave unburned fuel in the cylinder, which can ignite erratically. This causes light knocking or popping under load.

Replace ignition components at their recommended service interval to prevent long-term damage.

7. Engine Overheating

Excessive heat reduces the fuel’s resistance to auto-ignition and increases knock risk. Overheating may warp the cylinder head, damage the head gasket, and stress cooling system components.

8. Piston Slap

Piston slap occurs when the piston-to-cylinder clearance becomes excessive. It is common in high-mileage engines or engines cold-started in low temperatures.

Characteristics:

- Sharp slapping noise at cold start

- Noise decreases as the engine warms

While not immediately catastrophic, it indicates wear.

How to Diagnose Engine Knocking (Step-by-Step)

A structured diagnostic approach helps isolate the root cause:

1. Confirm the Type of Knock

- Pinging under load: combustion knock

- Deep rhythmic knock: rod knock

- Tap at cold start: piston slap

2. Check Oil Level and Oil Condition

Low or degraded oil can trigger mechanical wear.

3. Scan for OBD-II Fault Codes

Look for:

- Misfire codes (P030X)

- Knock sensor codes

- Timing-related codes

- Lean or rich fuel mixture codes

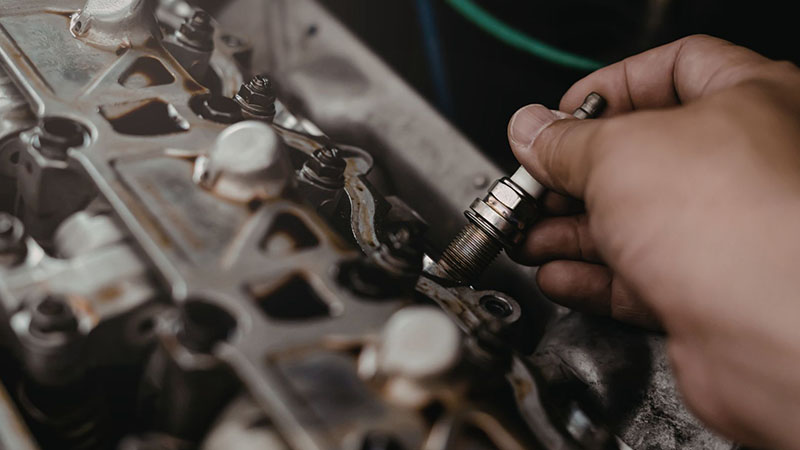

4. Inspect Spark Plugs

Worn or carbon-coated plugs offer insight into combustion quality.

5. Evaluate Fuel Quality

If the issue began after refueling, suspect low-octane or contaminated fuel.

6. Perform Compression or Leak-Down Test

Helps detect:

- Worn rings

- Valve issues

- Cylinder wear

7. Check Rod Bearing Play

A mechanic can identify bearing clearance through:

- Oil analysis for metal shavings

- Physical inspection after oil pan removal

8. Use a Mechanic’s Stethoscope

Pinpoint the noise source on the block, head, or lower end.

How to Fix Engine Knocking

The repair method depends entirely on the cause.

1. For Combustion-Related Knocking

- Switch to proper octane fuel

- Use high-quality fuel injector cleaner

- Clean carbon deposits (walnut blasting or chemical decarbonizing)

- Adjust ignition timing

2. For Ignition or Timing Issues

- Replace spark plugs and coils

- Repair timing chain or belt

- Replace crankshaft/camshaft sensors

- Update ECU programming if needed

3. For Mechanical Knocking

Mechanical engine knock often requires more extensive repair.

Rod Knock Repair

- Replace rod bearings

- Repair crankshaft journals

- Inspect oil pump

- Flush lubrication system

Piston Slap / Cylinder Wear

- Hone or rebore cylinders

- Replace pistons or rings

In many cases, when labor and parts costs accumulate, a full engine replacement becomes the more economical choice—especially for commercial fleets or high-mileage vehicles.

Is Engine Knocking Serious?

Yes—engine knocking is serious, and it almost always indicates abnormal combustion or developing mechanical wear.

Light pinging from low-octane fuel or mild detonation is usually manageable if corrected quickly, but deeper mechanical knocks—such as rod knock, bearing wear, or severe pre-ignition—can damage pistons, bearings, and crankshaft journals very rapidly.

In severe cases, the engine may fail suddenly or seize if driven further. Early diagnosis is critical to prevent catastrophic damage and avoid escalating repair costs.

Can You Still Drive With a Knocking Engine?

It depends on the type of knock:

- Light detonation or low-octane pinging: Generally safe for short distances, but should be corrected soon.

- Misfire-related knock: Usually safe to drive to a repair shop, but continued driving may worsen ignition or catalytic converter issues.

- Mechanical knock (rod knock, bearing wear, piston damage): Do not drive. These conditions can cause immediate engine failure or a seized engine.

If the knocking noise is loud, rhythmic, or increases with RPM, towing is the safest and most cost-effective option.

Engine Knocking Repair Costs

Repair costs for engine knocking vary widely depending on the underlying issue and the amount of labor required. Below is a general estimate of typical repair costs:

| Issue | Typical Repair Cost (USD) |

|---|---|

| Spark plugs / ignition coils | $50–$300 |

| Injector cleaning / carbon cleaning | $200–$450 |

| Timing adjustment or minor timing-related repairs | $150–$700 |

| Rod bearing replacement | $1,500–$3,000 |

| Piston and ring repair | $1,800–$4,000 |

| Full engine rebuild | $2,500–$4,500 |

| Engine replacement (long block / complete engine) | $2,000–$6,000 |

These ranges reflect typical pricing across independent repair shops, dealerships, and engine specialists. Actual costs vary by vehicle make, labor rates in your region, the extent of internal damage, and whether new, remanufactured, or aftermarket components are used.

How to Prevent Engine Knocking

Preventive maintenance is the most effective way to reduce the risk of engine knocking and extend engine life. The following practices address both combustion-related knock and mechanical wear:

- Use the correct octane fuel: Always follow the manufacturer’s recommended octane rating. Low-octane fuel can cause detonation and light pinging, especially under load or high temperatures.

- Maintain regular oil changes: Clean engine oil ensures proper lubrication of bearings, pistons, and valvetrain components. Running old or low oil increases friction and can lead to bearing wear, rod knock, and overheating.

- Clean or service fuel injectors periodically: Dirty injectors can cause lean fuel conditions, uneven combustion, and carbon buildup—common triggers for knocking.

- Replace spark plugs at the recommended interval: Worn or incorrect spark plugs affect ignition timing and combustion quality, increasing the likelihood of misfires and knock.

- Keep the cooling system in good condition: Overheating raises cylinder temperatures and increases the risk of pre-ignition and detonation. Ensure coolant levels, thermostat operation, and radiator performance are all within spec.

- Address Check Engine Lights promptly: Ignoring fault codes—especially those related to misfires, knock sensors, or fuel trim—can allow minor issues to escalate into serious engine damage.

Consistent maintenance not only prevents combustion knock but also helps avoid mechanical failures that lead to deep knocking noises, costly repairs, and engine replacement.

When Engine Knocking Means You Need a Replacement Engine

In some cases, engine knocking indicates damage severe enough that repairing the engine is no longer practical or cost-effective. This usually applies to bottom-end failures where internal components have suffered significant wear or heat damage. Situations that commonly justify engine replacement include:

- Rod knock with crankshaft damage: A worn or out-of-round crankshaft journal often requires machining or full replacement, which can exceed the engine’s value.

- Spun bearings: Spun rod or main bearings typically damage both the crankshaft and engine block, making rebuilds complicated and expensive.

- Deep cylinder scoring: Scoring caused by overheating, oil starvation, or debris may require reboring or sleeving the block—repairs that are labor-intensive and costly.

- Piston collapse or skirt fractures: These failures indicate extreme heat or stress and often spread debris throughout the engine, contaminating oil passages.

- Oil starvation with bottom-end damage: When bearings, crank journals, and connecting rods are compromised due to oil loss, restoring long-term reliability becomes difficult without a complete rebuild.

Because these failures require major machining, multiple new components, and carry a high risk of recurring issues, replacing the engine with a new or remanufactured long block or complete assembly is often the most reliable and economical solution.

FAQ

Can low oil cause engine knocking?

Yes. Low oil leads to insufficient lubrication and can cause rod knock, bearing failure, or camshaft wear.

Is engine knocking expensive to fix?

Combustion knock is usually less expensive to address; mechanical knock can cost thousands.

Does thicker oil stop engine knocking?

It may reduce noise slightly, but it will not repair worn bearings or damaged components.

How long can a knocking engine last?

Mild detonation may let an engine run for a while, but damage builds up quickly. Severe rod knock, however, can destroy an engine in just minutes.

Is engine knocking the same as pinging?

Pinging is a type of combustion knock. Mechanical knocking is far more severe.

Conclusion

Engine knocking is always a warning that something inside the engine is operating outside its intended limits. While some causes—such as low-octane fuel, minor timing issues, or misfires—can be corrected relatively easily, others point to serious mechanical wear that can escalate into catastrophic failure if neglected.

Early diagnosis and timely repair are essential, whether you’re managing a workshop, supporting customers, or maintaining a fleet.

About Us

As a long-established manufacturer of complete engines, cylinder heads, crankshafts, and other powertrain components, Woda Auto provides OEM-quality replacement engines for Toyota, Hyundai, Nissan, Isuzu, GM, and many other major global brands.

For B2B buyers, distributors, and repair shops looking for reliable engine solutions, Woda Auto offers durable, ready-to-ship units engineered for professional performance and long-term dependability.

Contact us for detailed specifications, current availability, or a quotation—we’re here to support your business with high-quality, industry-proven engine products.