Rebuilding an engine means restoring it to like-new condition using specialized rebuild kits. It’s a process that can breathe new life into your vehicle—improving performance, reliability, and lifespan.

While most manufacturers offer engine rebuild kits, the quality can vary significantly. You may have heard of brands like EngineTech or EPWI—they’re trusted in the industry for a reason.

A machine shop can assist in measuring components like pistons and bearings to ensure a precise fit and prevent post-installation issues.

For many vehicle owners—especially those with high-capacity or diesel engines—rebuilding can be a much more budget-friendly alternative to replacing the engine entirely.

Benefits of Rebuilding an Engine

There are several compelling reasons to consider rebuilding your engine:

- Improved Performance: A rebuilt engine often runs smoother and more efficiently, with better power delivery.

- Extended Lifespan: High-quality rebuild kits can significantly prolong your engine’s life, minimizing the need for repeated repairs.

- Higher Resale Value: A rebuilt engine can increase the resale value of your vehicle, making it more attractive to potential buyers.

- Reduced Emissions and Oil Use: Rebuilding helps correct issues like oil burning and high emissions, contributing to a cleaner, more efficient engine.

- Preserve the Memory: For many owners, rebuilding an engine means holding onto a trusted vehicle full of history, use, and personal memories—whether it’s a family car or a loyal workhorse.

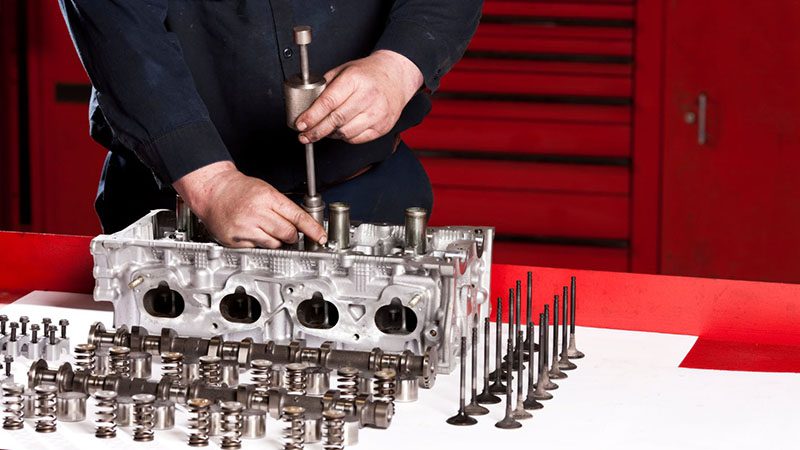

A successful rebuild hinges on the precision installation of key components—such as piston rings, bearings, gaskets and cranks.

Engine Rebuild Kits

Engine rebuild kits are the backbone of any successful engine overhaul. They come in a variety of configurations—ranging from basic kits to master or deluxe kits—depending on the scope of your rebuild and the engine type.

A typical rebuild kit includes all the key components, such as:

- Pistons and piston rings – crucial for maintaining compression and reducing oil consumption

- Main and rod bearings – to support the crankshaft and connecting rods under high loads

- Full gasket sets – to seal combustion chambers, coolant passages, and oil paths

- Valve seals and timing components – to restore proper valve timing and prevent leaks

More comprehensive kits may also include:

- Camshafts and crankshafts

- Bushings and lifters

- Oil pumps and timing chains or belts

- Expansion plugs, freeze plugs, and cylinder sleeves – especially useful when the engine block requires re-lining due to wear or damage

When selecting a rebuild kit, compatibility and quality are key. Trusted brands like Case IH, Reliance, EngineTech, EPWI and Woda offer kits designed to meet or exceed OEM specifications, with precision-machined components for better performance and durability.

Before ordering, you should carefully check the engine code, bore size, piston height, and bearing sizes to ensure a perfect fit. Incorrect sizing can lead to poor engine performance, dropped power output, increased wear, or even catastrophic failure after reassembly.

A well-matched rebuild kit not only simplifies the process—by bundling all the necessary parts into one package—but also reduces the risk of compatibility issues, shipping delays, or quality control problems.

It’s a smart move for both professional mechanics and DIY rebuilders looking to install components smoothly and complete a cost-effective overhaul.

Costs and Budgeting

Rebuilding an engine can be a smart long-term investment—but it’s important to understand all the costs involved to avoid surprises. Thinking ahead and preparing for both expected and unexpected expenses will help make the entire process smoother and more cost-effective.

Kit Costs

The price of an engine rebuild kit can range widely—from around $200 to over $1,500, depending on:

- The make and model of the engine

- Whether it’s a basic kit or a complete overhaul package

- The quality and brand

- Your location, which can affect shipping fees, taxes, and kit availability

Diesel and heavy-duty engine kits tend to be more expensive due to the size and complexity of the components. Higher-end kits often include extras like oil pumps, crankshafts, or camshafts, which add value but increase the cost.

Labor and Machine Shop Services

Labor is another significant cost—especially if you’re not doing the rebuild yourself. On average:

- Labor charges for an engine rebuild can range from $500 to $2,500+

- Machine shop services such as hot tank cleaning, cylinder honing, head resurfacing, valve work, or crankshaft grinding can cost an additional $300 to $1,000, depending on the extent of the work and local rates

In many cases, technicians will also need to remove old components—like stuck pistons, damaged bearings, or worn sleeves—before machining or reassembly can begin.

If the engine block needs to be bored or aligned, those costs can quickly add up. It’s essential to get a quote from a reliable machine shop before you dive in.

Additional Costs to Consider

Aside from parts and labor, other expenses may include:

- New engine oil and coolant

- Replacement of worn-out sensors, belts, or hoses

- Shipping fees for parts or kits

- Downtime costs if your vehicle is essential for daily use or business operations

Long-Term Savings

Although the initial investment may seem high, rebuilding your engine can save thousands in the long run. Compared to buying a new engine ($4,000–$10,000) or a replacement vehicle, a rebuild can be much more cost-effective—especially if the rest of the vehicle is in good condition.

A well-executed rebuild can also improve fuel efficiency, reduce repair frequency, and extend the engine’s life by tens of thousands of miles—thanks to the use of precision-machined parts and proper installation.

Tips for Budget Planning

- Always compare prices from multiple reputable vendors

- Ask machine shops for detailed breakdowns of service costs

- Leave room in your budget for unexpected issues—like cracked heads or damaged components found during disassembly

Considerations for Rebuilding

Before diving into an engine rebuild, ask yourself:

- Is the engine still structurally sound? If the block is cracked or the head is severely damaged, rebuilding might not be worth it.

- What’s the age and mileage? High-mileage or older model year engines can still be rebuilt, but the return on investment may be lower—especially if the vehicle is going to be sold to a customer or private buyer in the near future.

- Are you using a reputable kit and machine shop? Quality parts and precision workmanship make all the difference.

- Are future repairs likely? Consider whether the rebuild will resolve core issues or if you’ll need to spend more on additional repairs down the road.

Weighing these factors will help you recognize the point at which rebuilding is the right decision—and when it may be better to explore alternatives.

Alternative Rebuilding Options

If a full engine rebuild doesn’t seem like the right fit, there are several other repair strategies to consider. Each has its own pros, cons, and ideal use cases:

- Replace with a New or Used Engine

This option can save time, especially when quick turnaround is needed. However, brand-new engines are costly, and used engines may have hidden wear or reliability issues. - Repair Specific Components

In some cases, addressing specific problems—like a bad cylinder head, worn pistons, or leaking gaskets—can resolve the issue without rebuilding the entire engine. - Partial Rebuilds (Top-End or Bottom-End Only)

A partial rebuild focuses on either the upper part (cylinder head, valves, gaskets) or lower part (crankshaft, pistons, bearings) of the engine. It’s less costly and time-consuming than a full rebuild, but may not solve deeper engine issues.

| Option | Average Cost Range | Time Required | Pros | Cons | Best For |

|---|---|---|---|---|---|

| Full Engine Rebuild | $1,000 – $4,000 | 1–2 weeks | Cost-effective, extends engine life, eco-friendly | Labor intensive, downtime, requires expertise | Older vehicles in generally good shape |

| New Engine Replacement | $4,000 – $10,000+ | 3–5 days | Brand-new reliability, warranty included | Expensive, may not be cost-effective for older vehicles | Newer cars with extensive damage |

| Used Engine Replacement | $1,500 – $5,000 | 2–4 days | Faster, cheaper than new | Unknown history, may have limited warranty | Budget repairs with time urgency |

| Partial Rebuild (Top-End) | $800 – $2,000 | 2–5 days | Fixes common issues like valve damage | Doesn’t address lower-end wear | Valve, head gasket, or overheating issues |

| Component Repair Only | $200 – $1,500 | 1–3 days | Lowest cost, faster turnaround | Temporary fix, may miss underlying issues | Localized engine problems (e.g., oil leak) |

Each option depends on the vehicle’s condition, age, mileage, and your budget. For those with older, high-mileage vehicles in otherwise good condition, a rebuild can offer the most value. But in some cases, a partial repair or engine swap may be the smarter route.

Conclusion

Rebuilding an engine isn’t always the easiest route—but for many, it’s the most cost-effective and sustainable choice.

With a high-quality rebuild kit, a skilled hand at the machine shop, and some thoughtful budgeting, you can restore performance, improve fuel efficiency, and extend the life of your vehicle.

By weighing the pros and cons, you’ll be better prepared to decide if an engine rebuild is worth it—and if it is, you’ll be investing in many more miles of reliable driving.

At Nanjing Woda Auto Technology Co., Ltd., we specialize in supplying premium engine parts—including complete engines, rebuild kits, cylinder heads, crankshafts, and camshafts—to customers in over 100 countries.

Whether you’re a repair shop, distributor, or engine rebuilder, we’re here to support your success with reliable parts and professional service.

Contact us now to find the right engine rebuild solution for your needs—our team is ready to support you every step of the way.