Diesel engines are the backbone of heavy-duty vehicles, trucks, and construction equipment. They’re known for their durability and efficiency, but like any machine, they develop problems over time. If left unchecked, these issues can lead to costly downtime and major repairs.

In this guide, we’ll walk you through the basics of diesel engines, common problems, repair tips, and essential parts you’ll need to keep your engines running smoothly. Whether you’re a fleet manager, a mechanic, or a heavy equipment operator, this article is designed to help you diagnose issues, find solutions, and avoid future breakdowns.

Basics of Diesel Engines

A diesel engine works differently from a gasoline engine. Instead of using spark plugs, it relies on compression ignition—air is compressed until it’s hot enough to ignite fuel when it’s injected. This process delivers higher torque and better fuel efficiency, making diesels ideal for heavy loads.

Key diesel engine parts include:

- Fuel injectors – deliver pressurized fuel directly into the combustion chamber.

- Turbocharger – increases air intake for better combustion and power.

- Cylinder head & valves – control airflow and combustion.

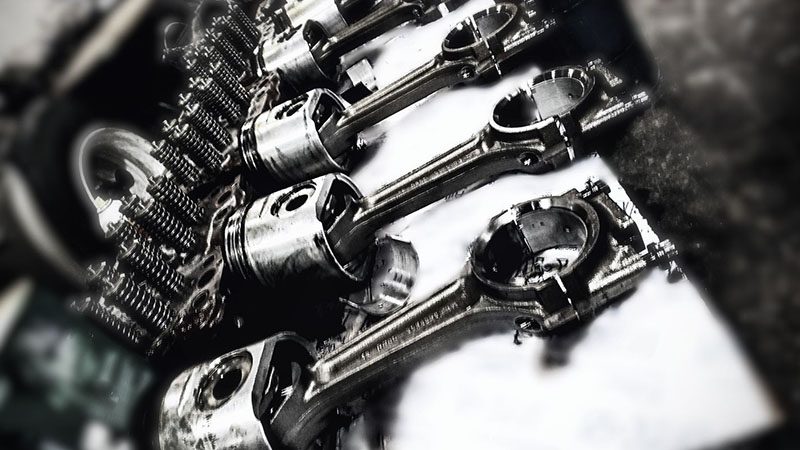

- Pistons & crankshaft – convert combustion into mechanical energy.

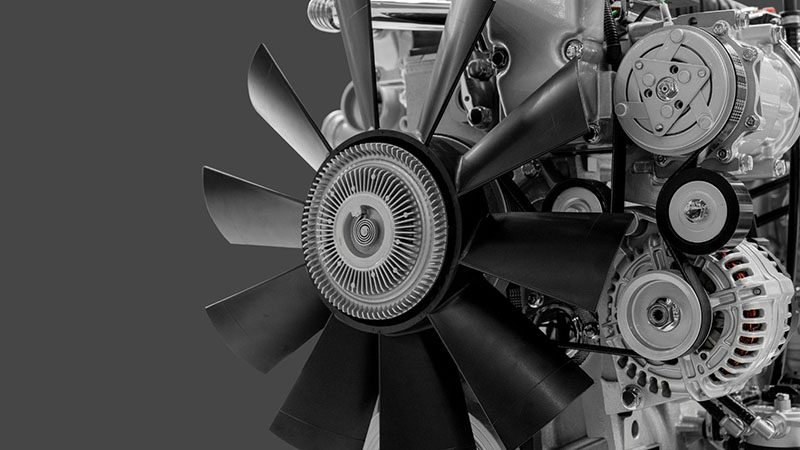

- Cooling system – regulates engine temperature and prevents overheating.

Common Diesel Engine Problems & How to Fix Them

Diesel engines are built for durability and long life, but like any machine, they can develop issues over time. The key to keeping them reliable is recognizing early warning signs and knowing the right fixes. Below are the most frequent diesel engine problems, their causes, and proven solutions:

Hard Starting Issues

A diesel engine that struggles to start is one of the most common complaints, especially in cold weather.

- Causes: Weak or faulty glow plugs, low compression from worn piston rings or valves, clogged fuel filters, or air in the fuel lines. In winter, fuel gelling from low temperatures can also restrict flow.

- Fixes: Replace worn glow plugs, bleed air from fuel lines, test the fuel pump for proper pressure, and run a compression test. For cold climates, use winterized diesel fuel or anti-gel additives.

Excessive Smoke (Black, White, or Blue)

Smoke color is a quick diagnostic tool for diesel problems.

- Black smoke: Indicates an imbalance of too much fuel or not enough air, often caused by dirty air filters, bad injectors, or turbocharger failure.

- White smoke: Usually unburned fuel due to low compression, worn injectors, or coolant leaking into the combustion chamber (blown head gasket or cracked cylinder head).

- Blue smoke: Means oil is entering the combustion chamber through worn valve seals, piston rings, or turbo seals.

- Fixes: Clean or replace injectors, change clogged filters, adjust fuel timing, repair seals, and check for head gasket damage. If turbo failure is suspected, inspect shaft play and replace if necessary.

Loss of Power

A sluggish diesel engine can be frustrating and unsafe in heavy-duty applications.

- Causes: Restricted airflow (dirty air filter), clogged fuel filters, worn injectors, failing turbocharger, or EGR (Exhaust Gas Recirculation) valve problems. In modern engines, electronic control unit (ECU) faults may also limit performance.

- Fixes: Replace air and fuel filters, test injector spray patterns, check turbo boost levels, and clean or replace the EGR valve. For electronic issues, scan the ECU for error codes.

Overheating Problems

Diesel engines run hot, but consistent overheating signals deeper trouble.

- Causes: Low coolant, blocked or leaking radiator, broken water pump, stuck thermostat, or a failing fan clutch. In heavy-duty trucks, dirty intercoolers and radiators clogged with debris can restrict cooling efficiency.

- Fixes: Flush and refill the cooling system, replace the thermostat and faulty hoses, check the radiator cap for proper pressure, and inspect the water pump. Prevent overheating by keeping radiators clean and ensuring coolant is changed at recommended intervals.

Fuel System Issues

Since diesel engines rely on precise fuel delivery, fuel system failures cause major performance drops.

- Causes: Contaminated or poor-quality diesel fuel, algae growth in storage tanks, leaking fuel lines, or a worn high-pressure injector pump. Even small air leaks in the system can prevent proper combustion.

- Fixes: Drain contaminated fuel, clean tanks, and replace fuel filters regularly. Repair or replace worn seals and injector pumps, and ensure fuel lines are airtight. Using fuel stabilizers can also help prevent contamination and microbial growth.

Diesel Engine & Heavy Equipment Repair

Diesel engines don’t just power trucks—they are the backbone of construction machinery, mining equipment, agricultural tractors, generators, and marine vessels. In these industries, even a single breakdown can halt operations, causing lost productivity, missed deadlines, and significant financial losses.

For fleet managers and contractors, keeping engines reliable isn’t only about repair—it’s about protecting high-value assets and ensuring projects stay on schedule.

Heavy equipment also works in some of the harshest environments—dusty construction sites, muddy farms, or extreme mining conditions. These conditions put additional strain on diesel engines compared to standard road vehicles.

A small issue, such as a clogged filter or minor coolant leak, can quickly escalate into overheating, power loss, or even complete engine failure if ignored.

This is why preventive repairs are far more cost-effective than emergency fixes. To illustrate the difference:

| Aspect | Preventive Repairs | Emergency Repairs |

|---|---|---|

| Timing | Scheduled during planned maintenance | Sudden and unexpected, often at peak usage |

| Cost | Lower overall — routine part replacements and inspections | Much higher — major part failures, urgent labor, towing, and downtime expenses |

| Parts Used | OEM-quality replacements installed before failure | Full assemblies often required (injector pumps, turbos, cylinder heads) |

| Downtime | Minimal — short, planned service windows | Significant — equipment may be offline for days or weeks |

| Impact on Operations | Keeps fleets reliable, prevents costly work stoppages | Halts construction, mining, or farming operations, leading to missed deadlines |

| Engine Lifespan | Extends service life by thousands of hours/miles | Reduces lifespan due to repeated high-stress breakdowns |

| Long-Term ROI | High — steady performance, lower cost of ownership | Low — unpredictable expenses and shorter service life |

As the table shows, investing in preventive strategies with OEM-quality parts reduces downtime, lowers costs, and extends equipment life. For companies that rely on diesel-powered fleets and machinery, this proactive approach delivers the best long-term return on investment.

Diesel Engine Parts You’ll Need for Repairs

When repairing a diesel engine, there are several components that are commonly replaced due to wear, stress, or failure. Understanding their roles helps highlight why sourcing the right parts is so important:

- Glow Plugs – Essential for cold starts, especially in colder climates. Weak or burnt-out glow plugs make diesel engines hard to start and put extra strain on batteries and starters.

- Fuel Injectors – Deliver precise amounts of fuel into the combustion chamber at extremely high pressure. Dirty or leaking injectors can cause misfires, smoke, poor fuel economy, and even piston damage.

- Crankshafts – One of the most critical rotating components, converting piston motion into rotational energy. A worn or cracked crankshaft can lead to catastrophic engine failure, making quality machining and balance vital.

- Cylinder Heads – House the combustion chambers, valves, and injectors. Warping, cracking, or gasket failure in cylinder heads can cause overheating, coolant leaks, or loss of compression.

- Pistons & Rings – Withstand extreme heat and pressure during combustion. Worn rings lead to low compression and oil consumption, while damaged pistons can cause complete engine breakdown.

- Turbochargers – Boost efficiency by forcing more air into the combustion chamber. A failing turbo results in power loss, excessive smoke, or oil leaks into the intake/exhaust system.

Because diesel engines operate under high temperatures, heavy loads, and extreme pressure, these parts are the most vulnerable to wear and failure. Replacing them with reliable, tested components ensures longer service life, consistent performance, and reduced risk of costly breakdowns.

Preventive Maintenance Tips to Avoid Future Issues

While strategic planning helps businesses reduce downtime, everyday maintenance is just as important. Simple, consistent practices can prevent most diesel engine failures before they happen. Here’s a quick checklist to follow:

- Change oil and filters regularly – Keeps components lubricated and fuel delivery clean.

- Use high-quality diesel fuel – Prevents injector wear from water or contamination.

- Inspect the cooling system – Monitor coolant levels, hoses, and radiators to avoid overheating.

- Check injectors and compression – Ensures efficient combustion and detects wear early.

- Avoid long idling – Reduces carbon build-up and improves fuel efficiency.

- Choose OEM-quality parts – Reliable replacements extend engine life and reduce breakdowns.

Consistent preventive maintenance not only boosts reliability but also ensures engines run at peak performance, helping avoid unplanned and costly repairs down the road.

FAQs

1. Is a diesel engine expensive to repair?

Yes. Their high-pressure fuel systems and heavy-duty parts make repairs costlier, and labor is often specialized.

2. Are diesel engines easy to fix?

Basic upkeep is simple, but major repairs usually need professional tools and expertise.

3. Is it worth rebuilding a diesel engine?

Yes—if the block is solid, rebuilding is often cheaper than replacing and can extend engine life by years.

4. What’s the worst thing for a diesel engine?

Contaminated fuel, skipped maintenance, overheating, and long idling cause the most damage.

5. How long will a diesel engine last?

With proper care, most last 300,000–500,000 miles (480,000–800,000 km), and heavy-duty models often go beyond.

Conclusion

Fixing diesel engines comes down to early diagnosis, quality repairs, and preventive maintenance. From hard starting and smoke issues to overheating and power loss, most problems can be traced back to fuel, air, or cooling system faults.

For long-lasting repairs, always use trusted parts and suppliers. Whether you’re maintaining a truck fleet or repairing heavy equipment, investing in high-quality diesel engine parts will save you downtime and costs in the long run.

Need dependable engine parts? Contact Nanjing Woda Auto Technology today to explore our catalog and request a quote.