The words compression ratio get thrown around a lot whenever there is a talk about the engine’s health or its performance glitches. If you know how to calculate the compression ratio, you can then cross-check these numbers with a test and set up your plan of action next.

This guide will help you explain everything about it in layman’s terms!

What Is the Compression Ratio of an Engine?

The compression ratio is the static compression ratio readings of the engine.

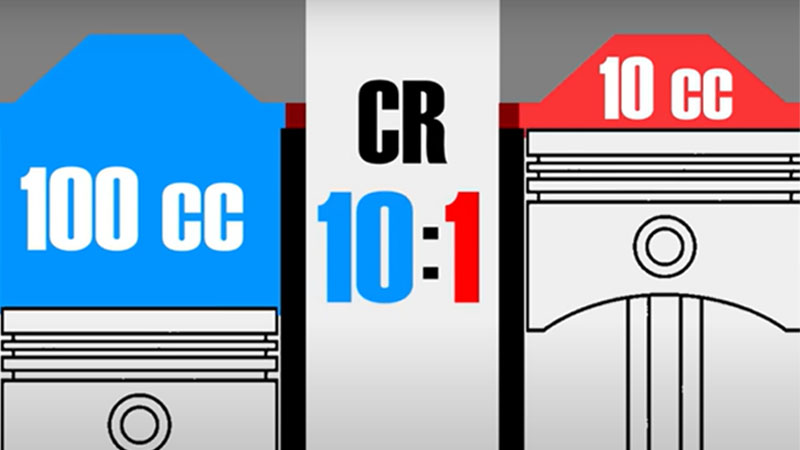

So basically, it is the ratio between your largest and smallest volumes of an engine cylinder set by the position of the piston.

Well, the largest volume of your cylinder is all set by the position of the piston at “bottom dead center.” On the flip side, the smallest cylinder volume is when the piston is at “top dead center.”

For example, if the largest cylinder volume, when the pistons are at bottom dead center, is 100 CC, and the smallest cylinder volume at the top dead center is 10 CC, you get a 10:1 compression ratio.

This ratio determines how much the air-fuel mixture is compressed in the engine. However, the higher and lower compression ratios can mean different things, which is not good news for you.

How Do I Calculate Compression Ratio of an Engine?

To calculate the compression ratio, you need to know a few things about your engine:

- Size of engine bore (cylinder size).

- Length of engine stroke (how far the piston moves from top to bottom).

- Compressed head gasket thickness.

- Head gasket bore (size of head gasket).

- Piston top and block deck distance (how far the piston sits from the block at the top).

- Piston dish volume.

- Combustion chamber volume (space in the combustion chamber when the piston is at the top).

Once you have these readings, you can calculate the compression ratio manually, but as it requires some effort and time, you can do this with a readily available, free-to-use online compression ratio calculator.

Just fill in the readings according to your engine specs, click “Calculate Compression Ratio” or “Calculate CR,” and you get the results instantly.

After you calculate, convert the reading to PSI. For example, if you got a 9.56:1 reading, divide 9.56 by 1 and multiply it by the atmospheric pressure (It is usually 14.7 PSI), so the compression ratio reading in PSI is 140.53 PSI.

Once you get that optimum reading in PSI, it is time to check it through a gauge to see if the engine actually has that compression, higher, or lower.

How to Check Engine Compression with a Gauge?

Here is how you can check the compression ratio of your car engine with a gauge:

1. Warm up the engine till it reaches the operating temperatures.

2. Next, pull out the fuel pump fuse, which will stop fuel from entering the cylinders while cranking.

3. Now, remove spark plugs and wires/coils.

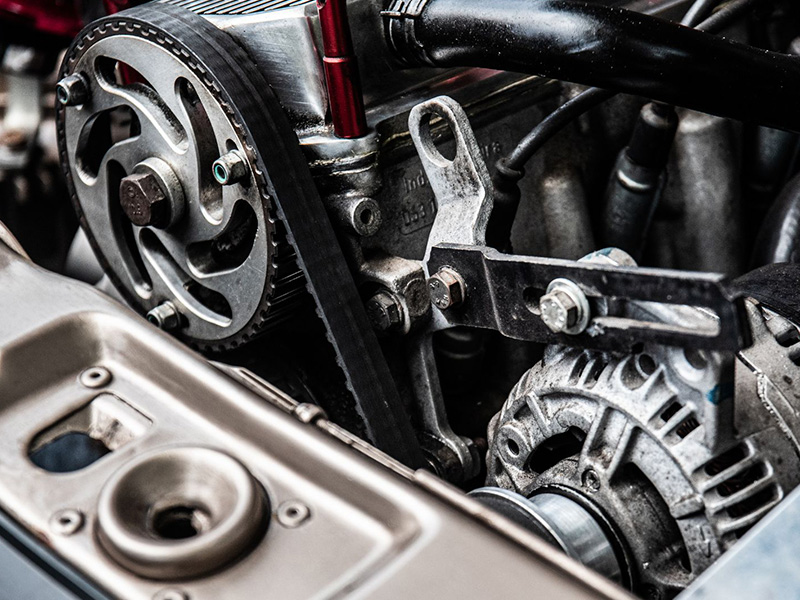

4. Put the compression gauge into the spark plug hole for Cylinder 1. To find it out, the Cylinder one is usually the first cylinder next to the timing belt and other accessories.

5. Now, floor the gas pedal to get maximum air intake, and then, crank the engine 4 to 5 times (in case of a 4-stroke engine) to note the reading for one full cycle.

6. In the next step, you need to crank the engine 10-12 times to get the maximum reading out of the compression gauge. Then, note this reading.

7. Press the relief valve on the side of the gauge to release the pressure and repeat the above steps in the rest of the cylinders.

8. Now that you’ve got all the readings, cross-check with the calculator you’ve used to calculate the optimal compression ratio of your engine, and you’ll find out its health based on higher or lower compression numbers.

What are the 7 Most Common Causes of Compression Loss?

If you get low compression readings with the gauge test on your engine, this could be due to any one of the following reasons:

- Cracked cylinder head

- Worn timing belt/chain

- Leaky valves

- Cylinder wall damage

- Head gasket failure

- Camshaft lobe wear

- Holes in pistons

- Worn piston rings

What Causes High Engine Compression?

As you drive along, the carbon deposits start to gather on the piston crown, cylinder head, and valves in your engine. This raises the compression figures, and you get higher readings on the gauge test.

One of the early signs is engine knocks. You can fix it temporarily with the use of a higher octane fuel, but this is just a band-aid for the worst that is yet to come.

It’s also possible that you’ve installed an incorrect piston or head gasket in an earlier rebuild that has changed the volume of the combustion chamber. The same goes for the incorrectly installed timing belts or chains, which can cause the valves to open or close at the incorrect times.

Another reason can be that the valves fail to seat accurately due to wear or damage, and this shows up as higher compression figures.

You may find it a bit surprising, but a choked catalytic converter limits the flow of the exhaust, which causes backpressure and results in increased compression readings.

How to Fix High or Low Compression In an Engine?

If the compression readings of your engine, whether high or low, are not up to specs, you are in for a rebuild. This means you need the help of a professional to take the engine out. They’ll inspect every motor component, and then may bore the cylinder head, change pistons, and replace valve seats, camshaft, and head gaskets to fix compression.

A worn timing belt or chain does not require the whole engine to be taken out, and only needs a partial teardown.

If the catalytic converter is the source of your high compression numbers, you can replace it without taking out the motor.

Conclusion

In this guide, you’ve learned how to calculate compression ratio with an online calculator and an easy way to run a compression test on your engine with a gauge. Repairs start afterward when you figure out the numbers are low or high according to your motor’s specs.

If you want to offer better and reliable products to your clients, Nanjing Woda Auto Technology Co., Ltd is your best choice. We have been serving worldwide since 1999 to provide all types of engine parts—from ignition systems and electrical setups to exhaust, suspension, and steering parts.

Reach out to Nanjing Woda today, and let’s talk about a lasting partnership that not only works for mutual benefit but also puts out a good name for your business when it comes to providing high-quality parts.