If you want your vehicle to perform well and achieve 100% fuel efficiency, you should keep clean fuel injectors. That’s how your engine lasts longer than usual. For auto parts dealers, wholesalers, retailers, etc., it’s necessary to develop a thorough understanding of the engine’s fuel system.

You must learn to appreciate the critical role of injector cleaning. This knowledge lets you provide expert advice to clients and build lasting customer loyalty. So, are you ready to start cleaning your car’s fuel injectors?

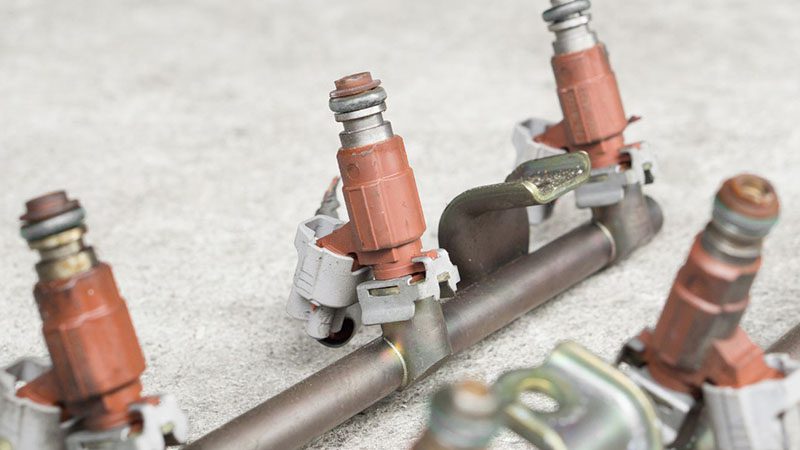

Fuel injectors are precision components. They’re tasked with delivering fuel into the intake manifold (or combustion chamber) in a finely atomized spray. Their condition directly affects gas mileage along with engine power and emissions.

However, over time, clogged fuel injectors stem from deposits of gasoline of poor quality. These contaminants and combustion byproducts clog your injectors, degrading the fuel system’s performance. We’ll also discuss how shady fuel can damage your engine’s fuel injectors.

Basically, this comprehensive guide covers how to identify symptoms of a poorly performing injector. It will tell you about the best cleaning process methods and preventive maintenance strategies. You’ll see what safe considerations to keep in mind to extend the lifespan of your fuel injectors in the 2020s.

Understanding the Fuel System and Its Components

The Fuel System: The Engine’s Lifeline

The fuel system of your vehicle is a complicated network. Its task is to deliver the right amount of fuel at the right pressure to your car’s engine. So, the fuel system’s many components have to work flawlessly.

- Fuel tank: This is the starting point where diesel or gasoline is stored. The fuel tank’s quality and how clean it is will impact the entire duel delivery process discussed below.

- Fuel pump: This component will pull fuel from the tank and pressurize it. It’ll push it through the fuel lines toward the fuel rail and then the injectors.

- Fuel filter: This filter will remove dirt and rust from the system, protecting the fuel pump/injectors.

- Fuel rail: The rail acts as a manifold that can distribute fuel to each injector evenly.

- Fuel injectors: Finally, our friend, the injector, delivers fuel in a precise, atomized spray pattern to the intake manifold (or directly into the combustion chamber).

Each component’s health is interdependent; a failure or clog in one can affect the entire fuel system.

The Critical Role of Fuel Injectors

Fuel injectors deliver fuel in a fine mist to the combustion chamber, we’ve learned. They make complete and efficient combustion happen! The quality of the spray pattern is very important here since even the slightest disruption caused by dirty injectors or deposits may lead to uneven fuel distribution. So, it will reduce the engine’s power, and emissions will increase.

Your engine either uses a carburetor or a fuel injection; each has its unique pros and cons. Suppose you use a fuel injection system. It comes in two primary types:

1. Port Fuel Injection (PFI)

These injectors spray fuel into the intake manifold just upstream of the intake valves. This system is very common in vehicles since it’s easier for mechanics to service.

2. Direct Injection (DI)

These injectors spray fuel directly into the combustion chamber. So, they offer better fuel efficiency but require more frequent (and specialized) injector cleaning due to higher vulnerability to carbon buildup.

Understanding these differences helps auto parts dealers recommend the right injector cleaner and fuel additives, depending on the vehicle type.

Why Regular Maintenance of the Fuel System is Essential

Clogged fuel injectors caused by deposits from low-quality gasoline can reduce atomization quality over time. So, you start seeing telltale symptoms like stalling, power loss, rough idle, decreased gas mileage, etc.

If you don’t address these symptoms in time, they can lead to engine damage and increased exhaust emissions. Regular maintenance using high-quality injector cleaner products and fuel additives prevents buildup, restores proper function, and prolongs the life of the fuel system components.

Identifying Problems and Maintaining Performance

Recognizing Symptoms of Clogged Fuel Injectors

Early detection of clogged fuel injectors can help you avoid costly repairs, especially when the client has a van or a large truck. Buses and larger trucks have 6+ fuel injectors; each injector costs $200 to $300. It will cost your clients $1.2k to $1.8k to replace all damaged fuel injectors if damaged by cheap fuel.

You can maintain client satisfaction by watching out for common symptoms, such as the following:

- Rough idle: The engine runs unevenly or vibrates a lot when standing still.

- Engine stalling: You notice sudden engine shutdowns even at low speed or when it’s idle.

- Decreases gas mileage: Noticeable drop in miles per gallon since it leads to increased fuel costs.

- Sudden power loss: Hesitation or sluggish acceleration during driving.

- Engine misfires: Detected at jerking or hesitation, often accompanied by a check engine light.

- Increased emissions: Failed emissions tests or visible smoke from the tailpipe.

Diagnostic Approaches for Auto Parts Professionals

Auto parts dealers and retailers can guide customers or service technicians through diagnostic steps to confirm injector-related issues:

- Visual inspection: You should examine the fuel rail, fuel lines, and injector connectors for leaks. Maybe the O-rings are damaged, or there’s corrosion somewhere.

- Fuel pressure test: You must verify that the fuel pump and fuel rail maintain the right pressure for efficient fuel delivery.

- OBD-II scanning: Try to identify injector-related error codes, e.g., P0200 to P0208.

- Injector balance testing: You can measure the consistency of fuel delivery across cylinders.

Preventive Maintenance Recommendations

You should encourage customers to use high-quality fuel additives and injector cleaner products. Do not forget to stress the importance of replacing fuel filters and inspecting fuel lines, making sure that these contaminants don’t reach the injectors.

Also, advise customers to schedule injector cleaning every 30k to 50k miles (or sooner in harsh driving conditions).

Cleaning and Maintenance Methods

Cleaning Fuel Injectors Without Removal

Non-removal cleaning methods are popular for routine maintenance and highly effective when performed correctly. Fuel injector cleaning kits connect to the fuel rail or fuel lines & circulate a specialized cleaning solution through the injectors while the engine runs.

This method dissolves deposits and restores a fuel injector’s spray pattern without any need for removal. It’s cost-effective and saves time.

You can suggest it to DIY enthusiasts and small-time mechanics. The cleaning solution contains detergents that break down varnish and carbon buildup, improving injector performance and restoring flow.

Professional Cleaning and Injector Removal

For severe clogging or persistent symptoms, professional cleaning methods are recommended:

- Ultrasonic cleaning: Injectors are removed. They are then immersed in an ultrasonic bath using high-frequency sound waves to dislodge stubborn carbon and varnish deposits successfully.

- Compressor-based cleaning: This method relies on pressurized air and solvents to flush injectors thoroughly. So, this cleaning method restores proper flow and spray.

Once cleaned, your injectors must undergo testing to make sure they’re 100% functional. Professional cleaning allows for prompt inspection & replacement of worn components like O-rings and seals.

Fuel System Flushing and Filter Replacement

A comprehensive fuel system flush removes contaminants from the fuel lines and the fuel rail. So, if you intend to prevent dirty injectors, you must replace the fuel filter from time to time. It’ll reduce strain on the fuel pump, too.

Moreover, flushing the system helps maintain the longevity of your fuel pump. It will reduce the risk of clogging & overheating as well.

Always advise customers to follow OEM maintenance schedules and procedures to ensure compatibility and avoid voiding warranties.

Preventing Clogs and Optimizing Engine Performance

Use of High-Quality Fuel and Additives

- You should recommend top-tier gasoline certified by TOP TIER™ Detergent Gasoline and similar organizations.

- Promote fuel additives that prevent deposits & maintain clean injectors to improve gas mileage.

- Explain to your clients how certain additives stabilize fuel quality during storage to reduce water contamination in the fuel tank.

Regular Maintenance Schedule

You should encourage customers to adhere to recommended injector cleaning intervals. Not only a fuel injector but also turbochargers must undergo periodic cleaning.

You may suggest regular inspection and replacement of fuel filters and fuel lines to prevent clogging issues. Remind customers that neglecting maintenance can lead to increased fuel consumption and costly repairs.

Avoid Low-Quality Gasoline and Additives

You should warn customers about the risk associated with using cheap gas and other unproven additives that may accelerate injector fouling or damage the fuel system.

A Wawa gas station in Bucks County, Pennsylvania, gained notoriety for selling cheap gas to customers, causing damage to their fuel systems, especially fuel injectors. Also, educate them on how poor-quality fuel causes premature wear on a fuel pump.

Fuel Tank and Fuel System Care

- You should tell your customers not to let the fuel tank run too low since this can cause dust or sediment to be drawn into the fuel lines, clogging injectors.

- You should also recommend periodic fuel tank cleaning if contamination is suspected, especially in older vehicles or those exposed to poor-quality fuel.

- Explain to clients how water and debris accumulation in the fuel tank can corrode components, degrading the performance of the fuel pump.

Professional Services for Complex Systems

- For vehicles with direct injection or advanced fuel systems, professional injector cleaning is vital.

- Retailers provide referrals or collaborate with local mechanics to offer these services, enhancing customer trust and satisfaction.

DIY Cleaning and Safety Precautions

Using a DIY Fuel Injector Cleaning Kit

DIY kits offer an accessible and cost-effective solution for customers. However, they require adherence to safety protocols. So, when your customers ask you if it’s okay to use DIY cleaning methods, you must inform them of these precautions:

- They have to disconnect the fuel pump & fuel lines safely before beginning the cleaning process.

- They’ll get a cleaning solution, adapters, and detailed instructions in their kits to ensure proper usage.

- Running the engine on the provided cleaning solution can help dissolve deposits and restore the proper function of the injector in question.

You should also emphasize the importance of following manufacturer instructions to avoid damage to the fuel system.

Safety Considerations

- Use PPE (personal protective equipment) like gloves and safety glasses.

- Work in a well-ventilated area to make sure you don’t inhale toxic fumes.

- Avoid open flames or sparks because of the flammable nature of fuel vapors.

- Dispose of used cleaning solutions and contaminated materials as per local regulations.

- Always keep a fire extinguisher nearby during the cleaning process to prevent accidents.

When to Recommend Professional Help

- If customers lack the tools or confidence to perform the cleaning process safely.

- This is for vehicles with complex direct injection systems or advanced fuel systems.

- When symptoms persist despite DIY efforts, indicating the need for professional diagnostics and cleaning.

Conclusion

Understanding the critical role fuel injectors play in the engine’s performance empowers you to better serve your customers.

Whether you’re a wholesaler, retailer, or auto parts dealer, you can easily educate customers on identifying symptoms of clogged fuel injectors, offer effective fuel injector cleaners, etc. It’s a chance to make your business a trusted partner in vehicle care.

At Nanjing Woda Auto Technology Co., Ltd., we are a global supplier of high-quality auto engine parts with over 25 years of industry experience. Our products are exported to more than 100 countries, trusted for their performance and value.

You can count on our expertise to deliver premium-quality fuel injectors and other essential engine components—affordably and reliably, right to your doorstep.

Contact us today to discover bulk pricing, customized product bundles, and expert support that will help you grow your business and keep your customers’ engines running smoothly and efficiently.