The Isuzu D-Max has been equipped with multiple four-cylinder diesel engines throughout its production history, with specifications varying by generation, market, and emissions standard.

For buyers, distributors, and workshops, identifying the correct engine model and code is critical when sourcing replacement engines or evaluating compatibility.

This guide outlines the Isuzu D-Max engine models by generation, detailing key engine codes, basic specifications, and application differences to support accurate identification and informed decision-making.

What engines are used in the Isuzu D-Max?

Across global markets, the Isuzu D-Max has consistently been offered as a diesel pickup, with most D-Max models powered by a relatively small group of four-cylinder turbo-diesel engines. These mainly include:

- Early-generation engines such as 4JA1 and 4JH1

- Common-rail diesel engines widely used in later models, including 4JK1 (2.5L) and 4JJ1 (3.0L)

- Newer-generation engines such as RZ4E (1.9L) and 4JJ3 (3.0L)

The specific engine fitted to a D-Max depends on the production generation, target market, and emissions standard, but these engine codes account for the majority of Isuzu D-Max vehicles worldwide.

Isuzu D-Max engine models by generation

Organizing Isuzu D-Max engines by generation is the most reliable way to identify which engine is fitted to a specific vehicle, as engine availability varies by production period and market.

First Generation Isuzu D-Max (approx. 2002–2011)

Early first-generation Isuzu D-Max models were offered with different diesel engine configurations depending on the target market and production year.

Common engines used during this period include:

- 4JA1-T (2.5L diesel)

- 4JH1-T (3.0L diesel)

As the generation progressed, Isuzu began introducing its common-rail i-TEQ diesel engines, which later became the foundation of the D-Max engine lineup:

- 4JK1 (2.5L common-rail diesel)

- 4JJ1 (3.0L common-rail diesel)

What this means:

If you are dealing with an early-2000s D-Max—particularly in parts of Asia or developing markets—you may still encounter references to 4JA1 or 4JH1 engines. Vehicles produced later within the same generation are far more likely to be equipped with 4JK1 or 4JJ1 engines.

Second Generation Isuzu D-Max (approx. 2012–2019)

This is the generation most users are referring to when searching for Isuzu D-Max engine models, as it was widely sold and exported.

The engine lineup during this period is more standardized:

- 4JK1-TC (2.5L turbo diesel)

- 4JJ1 (3.0L turbo diesel)

Both engines belong to Isuzu’s common-rail diesel family and were used across many global markets. While power and torque figures vary by year, market, and emissions standard, the engine codes remain the primary and most reliable identifiers.

This generation is particularly common in:

- Fleet and commercial applications

- Export and replacement engine markets

- Regions where durability and straightforward servicing are priorities

Third Generation Isuzu D-Max (2019/2020–present)

The current generation of the Isuzu D-Max features a more modern diesel lineup, with a stronger emphasis on fuel efficiency, emissions compliance, and improved torque output.

Common engines include:

- RZ4E-TC (1.9L turbo diesel)

- 4JJ3-TCX (3.0L turbo diesel)

The 1.9L RZ4E engine is designed for improved fuel efficiency and everyday usability, while the updated 3.0L 4JJ3 remains the preferred option for heavier workloads and towing, where offered.

Common Isuzu D-Max engine models at a glance

| Engine Code | Displacement | Typical Usage | Notes |

|---|---|---|---|

| 4JA1-T | 2.5L | Early first generation | Older indirect-injection diesel design |

| 4JH1-T | 3.0L | Early first generation | Early 3.0L diesel option |

| 4JK1-TC | 2.5L | Late first gen / second gen | Common-rail turbo diesel, widely used |

| 4JJ1 | 3.0L | Late first gen / second gen | Most widely used global D-Max engine |

| RZ4E-TC | 1.9L | Late second gen* / third gen | Efficiency-focused modern diesel |

| 4JJ3-TCX | 3.0L | Third generation | Updated high-torque diesel engine |

* RZ4E appears mainly in late second-generation facelifts and becomes standard in third-generation models, depending on market.

Key Isuzu D-Max Diesel Engines Explained

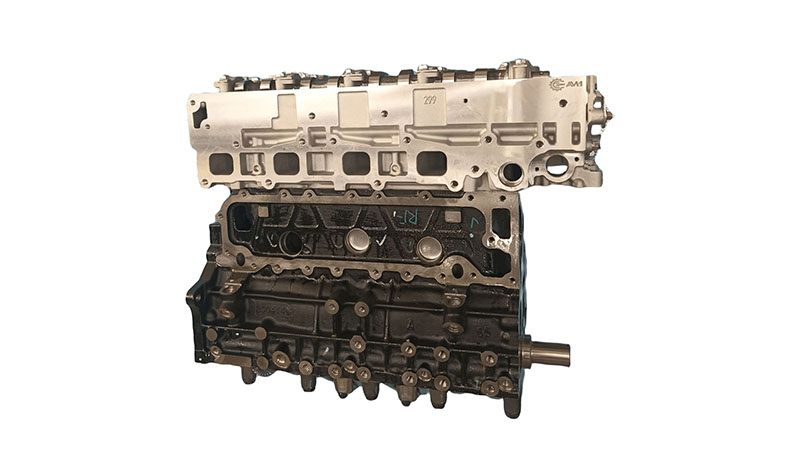

Isuzu 4JJ1 (3.0L Diesel)

The 4JJ1 is one of the most widely recognized Isuzu D-Max engines worldwide. It has been used across multiple generations and markets, which is why it frequently appears in engine searches, service discussions, and replacement inquiries.

Key reasons for its popularity:

- Strong low-end torque suited for work-oriented applications

- Proven durability in long-term commercial and fleet use

- Broad availability of parts and technical support in many regions

Important note:

The 4JJ1 is not a single, fixed specification. Power output, fuel injection components, turbo configuration, and emissions equipment can vary depending on production year, market, and regulatory requirements.

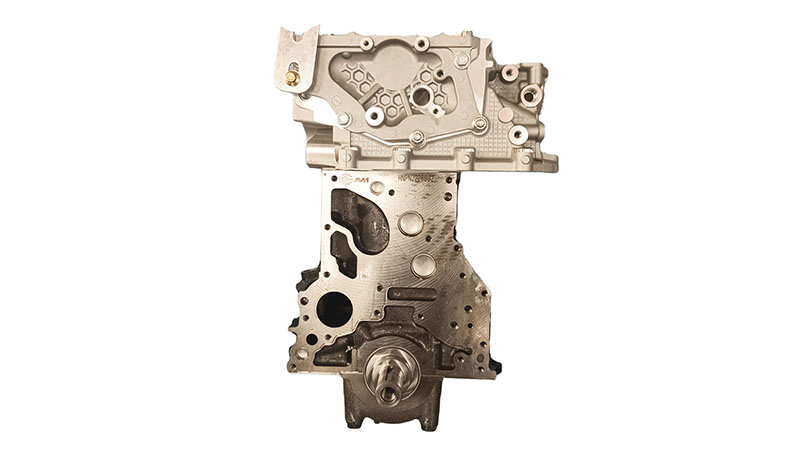

Isuzu 4JK1 (2.5L Diesel)

The 4JK1 is commonly found in second-generation Isuzu D-Max models and is often selected for its balance between operating cost and everyday practicality.

Typical characteristics include:

- Smaller displacement compared to the 4JJ1

- Competitive fuel efficiency, particularly in fleet operations

- Suitable performance for light to medium-duty applications

In many markets, the 4JK1 is relatively easy to source and maintain, making it an attractive option for cost-sensitive buyers and commercial users.

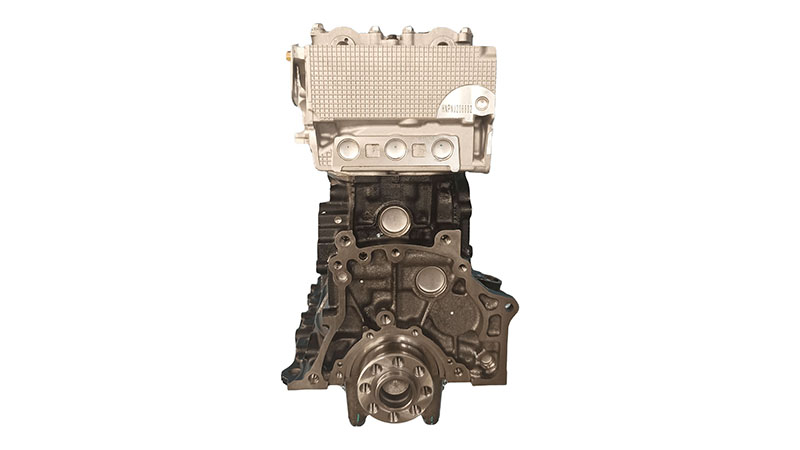

Isuzu RZ4E (1.9L Diesel)

The RZ4E 1.9L engine reflects Isuzu’s shift toward more modern, efficiency-focused diesel designs, particularly in newer D-Max generations.

Best suited for:

- Mixed city and highway driving conditions

- Fleets prioritizing fuel efficiency and lower running costs

- Markets with stricter emissions regulations

Despite its smaller displacement, the RZ4E delivers usable torque for everyday operation and is typically paired with more modern transmission options.

Isuzu 4JJ3 (3.0L Diesel)

The 4JJ3 is the current flagship diesel engine for the Isuzu D-Max in many markets and represents an evolution of Isuzu’s long-running 3.0L diesel platform.

Reasons buyers choose this engine:

- Higher torque output compared to earlier 3.0L variants

- Improved performance under sustained load and towing conditions

- Designed to meet modern emissions and efficiency standards

For heavy-duty use, towing, or demanding work environments, the 4JJ3 is often the preferred engine option where available.

4JJ1 vs 4JK1 vs RZ4E vs 4JJ3 – what’s the real difference?

While all four engines are turbocharged diesel units used in the Isuzu D-Max, they are designed for different operating priorities.

Isuzu D-Max Engine Comparison Table

| Engine Code | Displacement | Generation Use | Primary Focus | Torque Characteristics | Typical Applications |

|---|---|---|---|---|---|

| 4JK1 | 2.5L | Late Gen 1 / Gen 2 | Cost efficiency, practicality | Moderate torque, tuned for daily work | Fleet vehicles, light commercial use |

| 4JJ1 | 3.0L | Late Gen 1 / Gen 2 | Durability, versatility | Strong low-end torque | Heavy commercial use, export markets |

| RZ4E | 1.9L | Late Gen 2 / Gen 3 | Fuel efficiency, emissions | Balanced torque with lower fuel demand | Urban + highway fleets, emissions-focused markets |

| 4JJ3 | 3.0L | Gen 3 | High torque, modern performance | Highest torque output in D-Max range | Towing, heavy-duty and demanding workloads |

How to Interpret the Differences

The differences between these engines are best understood by looking at their design intent, torque delivery, and typical operating environments.

- 4JK1 (2.5L) is a smaller-displacement engine focused on efficiency and day-to-day practicality, commonly used in standard commercial and fleet applications.

- 4JJ1 (3.0L) represents Isuzu’s long-running workhorse platform, offering strong low-end torque, proven durability, and broad global parts support.

- RZ4E (1.9L) reflects a shift toward modern efficiency and emissions compliance, balancing usable torque with reduced fuel consumption.

- 4JJ3 (3.0L) is the most recent evolution of the 3.0L platform, delivering higher torque and improved drivability under sustained load.

These differences are primarily the result of design intent and operating focus, rather than simple performance rankings.

How to Choose the Right Isuzu D-Max Engine

Choosing the right engine depends mainly on how the vehicle will be used in practice, not just on specifications.

- Choose a 3.0L engine (4JJ1 or 4JJ3) if the vehicle regularly carries heavy loads, tows frequently, or operates in demanding or off-road conditions where torque and durability matter most.

- Choose a 2.5L engine (4JK1) if budget, availability, and predictable commercial use are the main considerations.

- Choose a 1.9L engine (RZ4E) if fuel efficiency, lower running costs, and mixed urban-highway operation are higher priorities than maximum torque.

In real-world use, the “best” Isuzu D-Max engine is the one that matches the operating environment, not simply the one with the highest output figures.

Is the Isuzu D-Max engine reliable?

Overall, the Isuzu D-Max has earned a strong reputation for reliability, particularly in commercial, fleet, and industrial applications where durability and uptime are critical.

In practice, long-term reliability is closely linked to maintenance quality and operating conditions, especially on modern common-rail diesel engines. Key factors include:

- Regular oil and filter changes, using oil specifications appropriate for the engine and emissions system

- Fuel quality, as common-rail injection systems are sensitive to contamination and water content

- Cooling system maintenance, including proper coolant type, correct service intervals, and attention to overheating risks

- Correct management of emissions components on newer models, such as EGR and DPF systems, which require suitable driving patterns and periodic maintenance

It is also worth noting that modern common-rail diesel engines prioritize efficiency and emissions compliance, which makes them more sensitive to poor maintenance or unsuitable operating conditions than older mechanical diesel designs. When serviced correctly, however, Isuzu D-Max engines are widely regarded as dependable and capable of high-mileage operation.

Common Isuzu D-Max engine problems

Most reported issues with Isuzu D-Max engines fall into predictable categories, particularly on modern common-rail diesel models.

- Emissions system issues: On newer engines, frequent short trips, extended idling, or irregular maintenance can lead to EGR or DPF-related problems, such as carbon buildup or regeneration issues.

- Fuel system sensitivity: Common-rail injection systems require clean, high-quality fuel. Contamination or delayed fuel filter replacement can cause rough running, starting difficulties, or power loss.

- Cooling and overheating: Cooling-related problems are usually maintenance-related. Coolant neglect, leaks, or restricted airflow can lead to overheating and potential engine damage.

These issues are not specific to Isuzu and are common across modern diesel engines. With proper maintenance and suitable operating conditions, D-Max engines are generally reliable in long-term use.

Engine replacement and compatibility tips

When sourcing or replacing an Isuzu D-Max engine for resale, fleet use, or export, accurate specification matching is essential. Engines sharing the same base code can still differ significantly in configuration.

Before confirming a purchase, always verify:

- Exact engine code and variant, including suffixes that indicate differences in fuel systems or emissions setups

- Production year and VIN, to ensure compatibility with the ECU, wiring, and ancillary components

- Emissions configuration (EGR, DPF, Euro standard), which directly affects installation and regulatory compliance in the destination market

- Transmission compatibility, particularly when engines are paired with different manual or automatic gearboxes

- Supply scope, such as long block, short block, or a complete engine with accessories (turbocharger, injectors, sensors, wiring, etc.)

For B2B buyers, incorrect matching often results in installation delays, additional modification costs, or delivery disputes. Confirming these details upfront helps ensure smooth installation, predictable costs, and reliable after-sales support—especially for volume or cross-border orders.

FAQ

What is the best engine for the Isuzu D-Max?

For heavy-duty use, the newer 3.0L engines are generally the best choice. For everyday commercial use, older 3.0L and 2.5L engines remain popular due to availability and service support.

What is the difference between 4JJ1 and 4JK1?

The main difference is displacement—3.0L vs 2.5L—along with torque output and typical applications. Both are common-rail turbo diesels used across multiple D-Max generations.

What engines are used in the new Isuzu D-Max?

Most current models use either the 1.9L RZ4E or the 3.0L 4JJ3 diesel engine, depending on market and trim.

Are Isuzu D-Max engines reliable?

Yes, when properly maintained. Regular servicing and fuel quality are key factors in long-term reliability.

Can Isuzu D-Max engines be replaced or swapped between generations?

In some cases, yes—but direct swaps are not guaranteed. Even engines with the same base code can differ in emissions systems, ECU calibration, wiring, and transmission compatibility.

Conclusion

When reviewing Isuzu D-Max engine models, the most reliable reference point is the engine code, not the vehicle name or trim level. Engine codes provide the clearest basis for identifying specifications, compatibility, and application differences across markets and production years.

For buyers, importers, and workshops, confirming the exact engine specification before purchasing or quoting is essential to avoid compatibility issues, installation delays, and unnecessary costs.

About us

Woda Auto is a China-based manufacturer and exporter specializing in automotive engines and engine components, with a focus on OEM-quality supply for B2B customers including distributors, repair networks, and fleet operators.

If you are sourcing an Isuzu D-Max engine for replacement, resale, or export, our team can support you with engine matching, technical verification, and supply options.

Contact us to discuss your requirements or request technical assistance.