Behind every roaring engine and smooth drive lies the crankshaft—a crucial component that transforms fuel ignition into rotational force, delivering engine power to the wheels. Often overlooked, it’s the unsung hero of internal combustion engines, bridging raw energy to motion.

In this article, we’ll explore the crankshaft’s design, role, and impact on engine performance while sharing maintenance and repair tips to keep it running at its peak. Buckle up as we uncover how the crankshaft unlocks your engine’s true potential.

What is a Crankshaft?

A crankshaft is an essential powerhouse within a reciprocating engine, seamlessly transforming linear motion into rotary motion.

Acting as the engine’s dynamic core, it masterfully converts the up-and-down movement of the pistons into a smooth rotational force.

This precision-engineered shaft, driven by a sophisticated crank mechanism, plays a pivotal role in the engine’s power transmission system, ensuring the efficient transfer of energy from reciprocating motion to continuous rotation.

Its function is nothing short of a mechanical marvel, enabling engines to deliver the power that drives motion.

What Makes Up a Crankshaft?

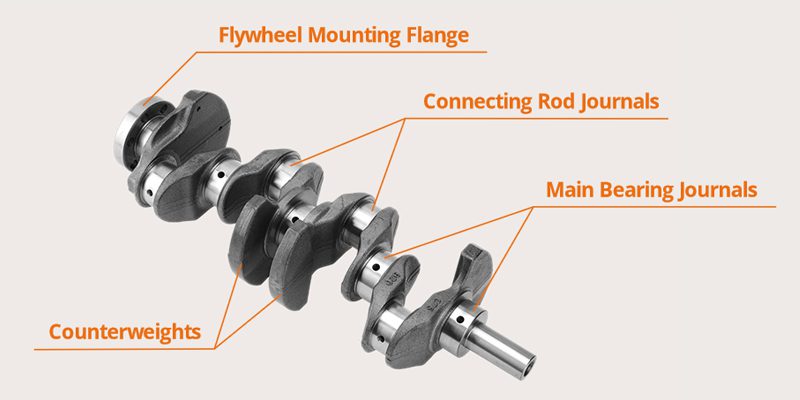

1. Crankshaft Journals

Crankshaft journals are the connection points that allow the crankshaft to rotate within the engine block. They come in two main types:

- Main Bearing Journals: These act as the central axis of rotation, firmly clamped into the engine block to provide stability and precision.

- Connecting Rod Journals: Also referred to as rod bearing journals or crank pins, These are attached to the ends of the connecting rods and transfer the motion of the pistons to the crankshaft.

Both types of journals are precision-machined to ensure smooth movement and are often hardened to withstand the stresses of high-speed operation.

2. Counterweights

Counterweights are specially designed weights integrated into the crank web, serving a crucial role in counteracting opposing forces.

As the crankshaft spins, it faces powerful rotational forces, while the up-and-down movements of the connecting rod and piston create significant stress.

To counter these dynamic forces, counterweights are precisely cast as part of the crankshaft itself. Acting as mechanical balancers, they ensure smooth, stable rotation even under the intense demands of high-speed operation.

3. Flywheel Mounting Flange

The flywheel mounting flange connects the crankshaft to the flywheel, offering a sturdy and precise surface for secure attachment.

It transfers the crankshaft’s rotational energy to the flywheel, enabling smooth power delivery and efficient engine performance.

4. Crankshaft Webs

Crankshaft webs are the structural elements that connect the main bearing journals to the counterweights.

They provide strength, balance, and stability, ensuring smooth engine operation. By absorbing and distributing stresses, crankshaft webs help maintain proper alignment and enhance the durability and performance of the crankshaft.

5. Thrust Washers

Thrust washers are small yet crucial components that control the axial movement (endplay) of the crankshaft, ensuring proper alignment and smooth operation under varying engine loads.

Acting as bearings, they reduce friction and wear, maintaining crankshaft stability.

6. Main Oil Seals

Main oil seals in a crankshaft system are designed to prevent oil leaks while allowing the crankshaft to rotate smoothly.

These oil seals maintain proper lubrication by keeping engine oil within the crankshaft system while blocking contaminants, debris, and external elements from entering.

How Does a Crankshaft Work?

The crankshaft is a mechanical marvel that transforms the linear motion of the pistons into smooth, continuous rotational motion.

This transformation is essential for powering your vehicle, as the rotational motion drives the wheels and enables the engine to operate.

Once the crankshaft completes its conversion of motion, it transfers this rotational energy to the camshaft, ensuring the entire engine operates in perfect harmony.

Here’s a detailed step-by-step breakdown of how the crankshaft operates:

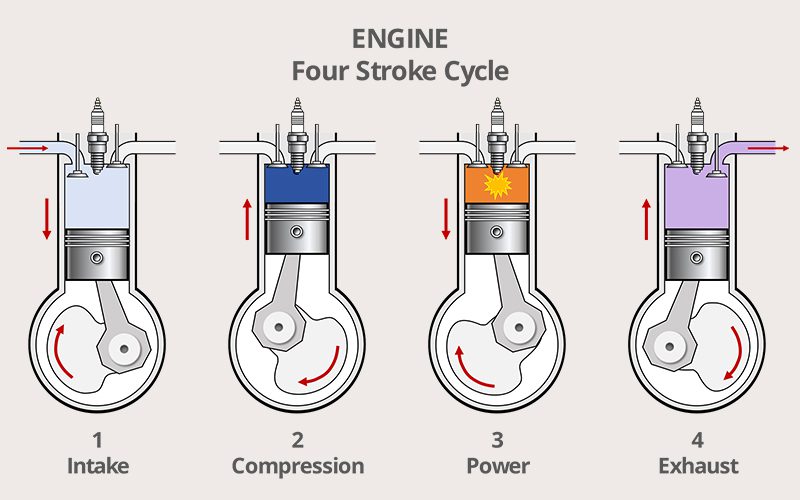

1. Piston Movement Initiates the Process

The engine’s pistons move in a straight, vertical line (linear motion) within their respective cylinders, guided by the cylinder walls. This movement occurs as a result of the combustion of fuel and air in the combustion chamber, creating pressure that pushes the pistons up and down during the power stroke.

2. Connection to the Connecting Rods

The pistons are connected to the crankshaft through connecting rods. As the pistons move up and down, they push and pull on the connecting rods, transferring their linear motion to the crankshaft.

3. Crankshaft Rotates

The motion of the connecting rods causes the crankshaft to rotate. This is made possible by the crankshaft’s unique design, which includes offset journals. These offset journals allow the crankshaft to pivot with the up-and-down motion of the pistons, converting their linear motion into rotational motion.

4. Energy Transmission to the Camshaft

Once the crankshaft rotates, it transfers its rotational energy to the camshaft through the timing chain or timing belt. The camshaft then works in harmony with the valve train to precisely control the timing of engine valves, ensuring they open and close at the right moments. This process allows fuel and air to enter the combustion chamber and exhaust gases to exit in a highly coordinated manner.

5. Power Delivery to the Wheels

Finally, the rotational energy from the crankshaft is sent to the transmission system, which then transfers this power to the vehicle’s wheels. This final step allows the vehicle to move, translating the engine’s internal power into motion on the road.

What Types of Crankshafts Are There?

Crankshafts come in a variety of types, each defined by its unique manufacturing process and intended application. These different types of crankshafts are engineered to meet specific performance requirements, durability, and design needs in modern engines. Below are the most common types of crankshafts:

1. Cast Crankshafts

Cast crankshafts are produced by pouring molten metal into a mold to achieve the desired shape. While they are generally less expensive to produce compared to other types, cast crankshafts are suitable for standard production vehicles and lighter-duty applications due to their affordability and sufficient strength.

2. Forged Crankshafts

Forged crankshafts are created by heating a solid block of steel until it becomes red-hot and shaping it under extremely high pressure.

This process produces a dense, strong, and highly durable crankshaft, making it ideal for performance and heavy-duty engines. They are favored in high-performance applications because they can withstand immense stress and operate at high speeds with reliability.

3. Billet Crankshafts

Billet crankshafts are typically made from high-quality steel and are known for their strength and durability. In addition to steel, billet crankshafts often contain alloy elements such as molybdenum, aluminum, chromium, and nickel. These additions improve their performance, wear resistance, and overall reliability, making them popular in performance and racing engines.

What Else Should You Know?

1. Common Issues

The crankshaft is a strong and reliable component, but it can encounter several common issues over time. Recognizing these problems early can prevent costly repairs and engine failure.

- Crankshaft Bearing Wear: Worn bearings, caused by lack of lubrication, excessive stress, or aging, can lead to metal-on-metal contact, causing noise, vibrations, and damage to the crankshaft. To learn more about how long crankshaft bearings typically last, check out this detailed guide on HowStuffWorks.

- Crankshaft Misalignment: Misalignment—due to manufacturing defects, improper installation, or wear—can cause uneven stress, vibrations, and reduced engine performance.

- Crankshaft Cracking or Damage: Physical damage or cracks can occur from over-revving, sudden impacts, or excessive stress. These can lead to catastrophic engine failure if not addressed promptly.

- Worn or Damaged Counterweights: Counterweights maintain crankshaft balance. When worn or damaged, they can lead to vibrations, instability, and poor performance.

- Flywheel Mounting Flange Issues: A damaged or misaligned flywheel flange can disrupt power delivery, causing vibrations and reduced engine efficiency.

2. Symptoms of crankshaft problems in a car engine

- Engine Vibrations and Noise:Excessive vibrations, knocking, rattling, or banging sounds may indicate crankshaft imbalances, misalignment, or damaged bearings.

- Engine Misfires:Rough running, hesitation, stuttering during acceleration, or reduced power could result from disrupted engine timing due to crankshaft issues.

- Oil Leaks Around the Crankshaft Seal:Oil puddles under the car or a drop in oil levels often point to worn or faulty crankshaft seals. Address leaks immediately to avoid further engine damage.

- Difficulty in Starting the Engine:If the engine struggles to start or won’t turn over, a damaged crankshaft may be preventing proper rotation.

- Low Engine Performance and Reduced Fuel Efficiency:A noticeable drop in fuel economy and reduced responsiveness may be caused by crankshaft wear affecting engine timing and efficiency.

3. Maintenance and repair tips

Regular maintenance, timely oil changes, and early diagnosis can help prevent these issues. If you notice vibrations, noises, or performance issues, consult a mechanic to inspect and repair the crankshaft system.

Conclusion

To summarize, the crankshaft is a vital component that ensures the smooth and efficient operation of an internal combustion engine. This complex piece of engineering plays a key role in converting linear motion into rotational motion, enabling the engine to function properly.

Although typically reliable, the crankshaft can experience failure due to issues such as vibrations, bearing damage, or sensor malfunctions. If left unaddressed, a damaged crankshaft can lead to serious engine problems and costly repairs.

Regular maintenance and timely inspections are essential for keeping the crankshaft in optimal condition, ensuring that your engine continues to operate reliably and efficiently.

At Woda, we specialize in high-quality automotive engine parts and solutions. With over 20 years of experience in manufacturing and exporting automotive parts, we are dedicated to delivering reliable products and expert services to ensure your vehicle operates at its peak performance. Contact us today to discover how we can meet your engine needs.