If you’re planning to rebuild or replace an engine, you’ve likely come across the terms short block and long block. They sound similar, but the difference between them can have a major impact on your budget, installation time, and overall performance.

This guide explains what each engine type includes, how they differ, and how to choose the right option for your next rebuild or engine replacement project.

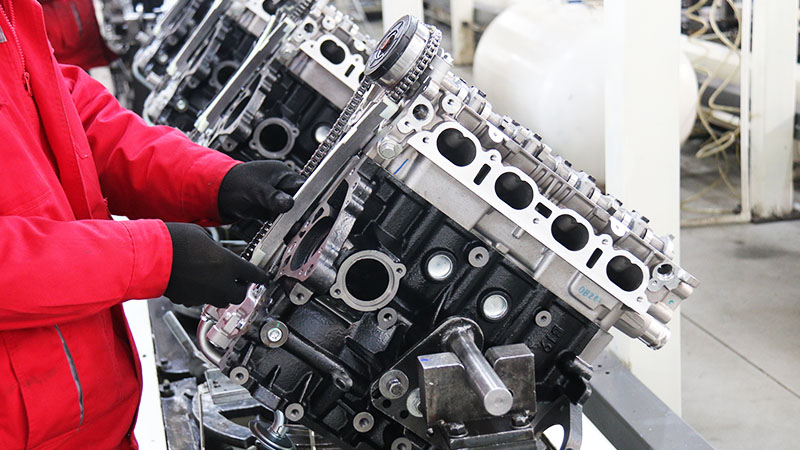

What Is a Short Block Engine?

A short block engine is essentially the heart of the motor — it includes the bottom-end components, but not the upper parts like the cylinder head or valve train.

A typical short block comes with:

- Engine block

- Crankshaft

- Pistons

- Connecting rods

- Bearings

What’s not included: the cylinder head, valves, camshaft, manifolds, and other top-end accessories.

Because it’s a partially assembled engine, the short block is ideal for those who want more control over what components go into their build — for example, performance tuners or shops that already have reusable parts from the original engine.

It also costs less upfront, making it an affordable foundation for a custom rebuild or engine restoration project.

However, it does require more assembly time, mechanical experience, and additional parts to get the engine running.

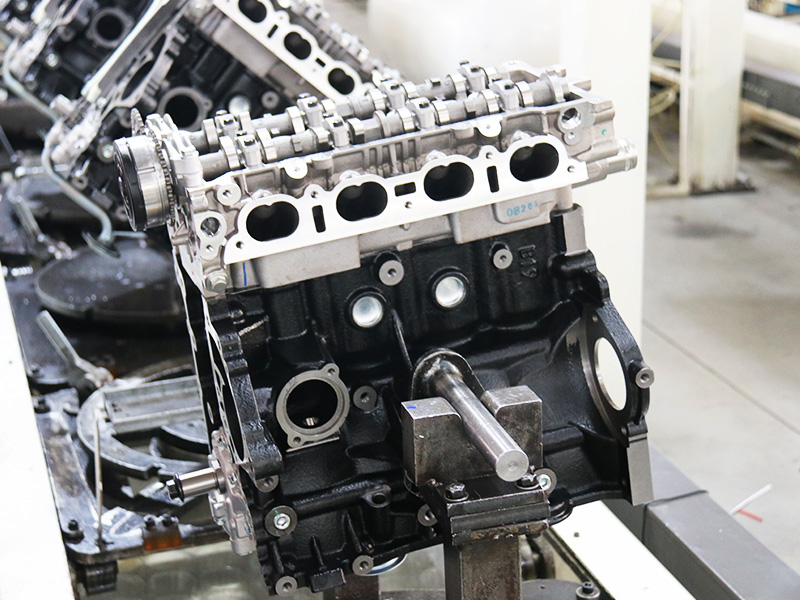

What Is a Long Block Engine?

A long block engine goes one step further. It includes everything a short block has, plus the top-end components like the cylinder head and valvetrain.

A typical long block includes:

- Short block assembly (block, pistons, crankshaft, rods)

- Cylinder head

- Camshaft(s)

- Valves and springs

- Rocker arms or lifters

- Timing components

In many cases, a long block is considered a “drop-in ready” option — meaning fewer parts need to be swapped or assembled before installation. For workshops or car owners who want to save time and reduce the chance of assembly errors, the long block is often the preferred choice.

It costs more than a short block but saves significant labor time, making it a good trade-off for those prioritizing convenience and reliability.

Short Block vs. Long Block: Key Differences

To help visualize how they compare, here’s a quick overview:

| Feature | Short Block | Long Block |

|---|---|---|

| Main Components | Engine block, crankshaft, pistons | Short block + cylinder head + valvetrain |

| Assembly Level | Partial | Nearly complete |

| Installation Time | Longer | Faster |

| Customization | High | Moderate |

| Cost | Lower | Higher |

| Best For | Performance builds, rebuilds | Quick replacements, daily drivers |

In short:

- Choose a short block if you want to customize, rebuild, or upgrade your engine step by step.

- Choose a long block if you need a near-complete engine that’s ready to install and start running.

Long Block vs. Complete Engine

This is another term that often causes confusion. If a long block already includes so many parts, what’s a complete engine?

A complete engine — sometimes called a crate engine or turn-key engine — is the most comprehensive option. It includes everything a long block has, plus:

- Intake and exhaust manifolds

- Fuel system and injectors

- Sensors and electronics

- Oil pan and valve covers

Essentially, a complete engine is ready to install, connect the wiring and fuel lines, and run.

The choice between a long block and a complete engine usually comes down to time and budget. Workshops handling high repair volumes often choose complete engines to minimize downtime, while rebuilders and tuners may opt for long blocks for more flexibility.

Advantages of a Short Block Engine

Short blocks are all about flexibility and control. For many builders and tuners, that freedom makes them a smart choice. Here’s why:

1. Lower Cost:

Since a short block only includes the bottom end — the block, crankshaft, pistons, and rods — the upfront cost is much lower. You’re not paying for parts you might already have, such as cylinder heads or camshafts, making it ideal for tight budgets or multi-engine rebuilds.

2. Customization Freedom:

A short block gives you full freedom to choose your own cylinder head, camshaft, and valvetrain setup. This makes it perfect for performance tuning, where builders can fine-tune compression, timing, and airflow to match specific power goals.

3. Ideal for Rebuilds:

If your top-end components are still in good condition, a short block lets you reuse them. It’s a cost-effective way to bring an engine back to life without replacing the entire assembly.

4. Perfect for Upgrades:

Whether you’re upgrading to forged internals or preparing for turbocharging, a short block is a solid foundation. It gives you the flexibility to build and modify at your own pace.

Of course, the trade-off is time and labor — you’ll need to source and assemble the missing components yourself. But for experienced builders or workshops, that’s often part of the reward.

Advantages of a Long Block Engine

Long blocks are all about convenience, reliability, and efficiency. They come pre-assembled with both the bottom-end and top-end components, making them a practical choice for quick, worry-free installations.

Here’s why they’re preferred by many workshops and rebuilders:

1. Ready to Install:

A long block is nearly complete when delivered — it includes the block, pistons, crankshaft, cylinder head, and valvetrain. You just add external accessories like manifolds or sensors, and it’s ready to go.

2. Lower Assembly Risk:

Since most components are factory-installed with proper torque and clearances, there’s far less chance of assembly errors or mechanical issues later on.

3. Saves Time and Labor:

Pre-assembled design means shorter installation times and faster turnaround — ideal for busy repair shops and fleet services where every hour counts.

4. Factory-Tested Reliability:

Many long blocks are pre-balanced and tested before shipping, ensuring consistent quality and dependable performance right out of the crate.

Although a long block costs more upfront, the time savings, reduced labor, and reliability often make it the more cost-effective option for professional installers and everyday drivers alike.

Which Is Better: Short Block or Long Block?

There’s really no one-size-fits-all answer — the better choice depends on your project goals, budget, and available resources. Both short blocks and long blocks serve different purposes, and understanding those differences helps you make the right investment.

If you already have good top-end components or want to build a performance engine from the ground up, a short block gives you the flexibility to choose every part and fine-tune the setup to your exact specifications. It’s ideal for experienced builders, tuning shops, or anyone who enjoys having full control over the assembly process.

On the other hand, if your priority is getting a vehicle back on the road quickly and reliably, a long block is usually the smarter choice. It comes mostly complete, requires less assembly, and often includes components that have been pre-tested for balance and quality — saving you time and minimizing installation risk.

Here’s a quick reference guide:

| Situation | Recommended Option |

|---|---|

| Rebuilding a damaged engine and keeping top-end parts | Short Block |

| Quick replacement with minimal labor | Long Block |

| Custom performance build or tuning project | Short Block |

| Workshop with limited assembly tools | Long Block |

| OEM-quality replacement for daily use | Long Block |

In short:

Choose a short block if you want control, customization, and a lower initial investment.

Go with a long block if you prefer a ready-to-install, factory-tested engine that saves time and labor while ensuring consistent reliability.

FAQ

What is better, short block or long block?

It depends on your goals. Short blocks are great for rebuilds or performance tuning, while long blocks are ideal for quick, complete replacements.

What is the difference between a short block and a long block?

A short block includes only the lower portion of the engine (block, pistons, crankshaft), while a long block adds the cylinder head and valvetrain, making it closer to a complete engine.

What are the advantages of a long block engine?

Long blocks save time, reduce assembly errors, and are ready to install. They’re ideal for workshops that want reliability and minimal downtime.

What are the advantages of a short block?

Short blocks cost less and allow full customization — perfect for tuners and rebuilders who want to choose their own components.

Conclusion

Choosing between a short block and a long block engine ultimately comes down to your priorities — customization and flexibility, or convenience and reliability. Knowing how they differ helps you invest wisely and keep your projects running efficiently.

About us

At Nanjing Woda Auto Technology Co., Ltd., we specialize in supplying OEM-quality bare, short, and long block engines built to meet global standards. With over 25 years of manufacturing experience, strict quality control, and worldwide shipping, we help distributors and professional workshops get reliable engine solutions that keep their customers satisfied and their operations running smoothly.

Looking for a trusted supplier for wholesale short or long block engines?

Contact Woda Auto today to get expert support and competitive pricing tailored to your business needs.