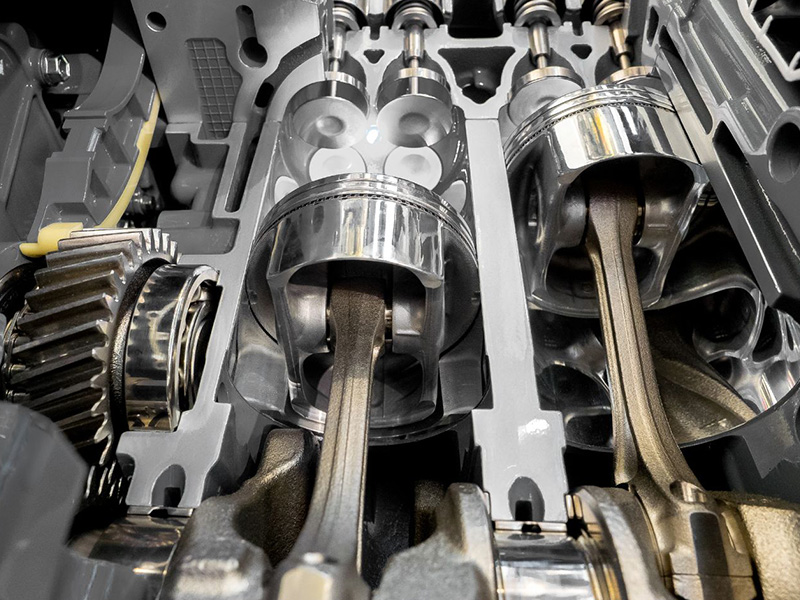

When you hear the term “stroker engine” or “stroker kit,” the first reaction is usually the same: What exactly does that mean? Is it about power, parts, or some special build trick? It’s one of the most common questions in the performance world, and that’s where this discussion begins.

What Is the Point of a Stroker Engine?

If you want more power out of your engine, one option is to simply fit a bigger one. But, this is a full swap, so you’ll be changing everything around the engine, like motor mounts, boost pipe, exhaust, or possibly gearbox, along with the ECU and the wiring. This sort of project costs a lot.

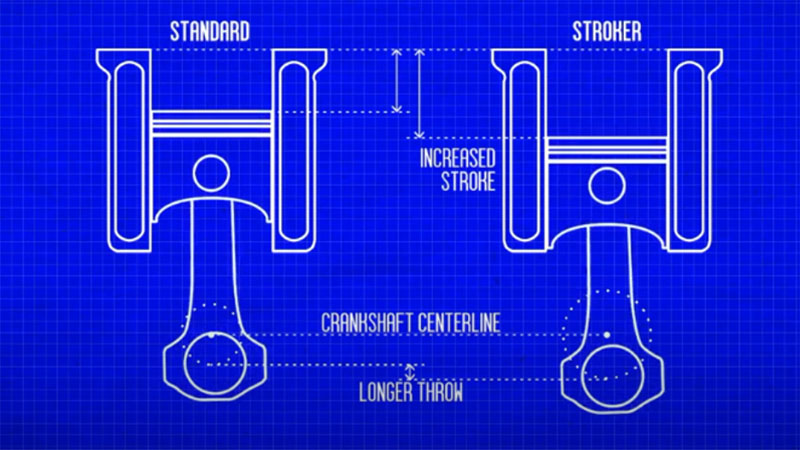

The other option, which is far easier, is to keep your existing engine and increase its piston’s stroke length. When you do this, the piston moves further into the cylinder bore, and you get increased displacement for more power.

This is what a stroker engine is.

How Does the Stoker Engine Work?

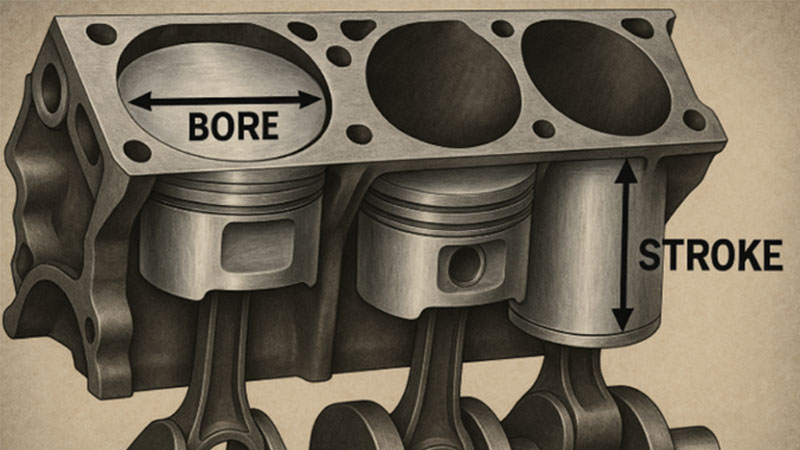

All piston engines rely on two basic design ingredients to define themselves: bore and stroke. The piston lives inside the cylinder bore, and the distance it moves within the same bore is called the stroke.

Both the bore size and the length of the stroke account for the engine’s displacement, which you can measure in cubic inches, cubic centimeters, or liters, and both of these elements carry distinct characteristics based on their dimensions.

So, what is engine displacement?

Well, it is the total measure of the cylinder volume which is swept by all pistons, but this does not include the combustion chamber.

The volume in a cylinder that is displaced by the piston during its movement from Top Dead Center (TDC) to Bottom Dead Center (BDC) is the swept volume. The piston’s motion creates this swept volume, which is an important factor when it comes to an engine’s size and its potential power.

The bore diameter is responsible for harnessing the power created in the combustion chamber. As the chamber fires and the air/fuel mixture expands rapidly, the piston is forced down into the bore.

The larger the bore is, the greater the force pushing the piston down.

The stroke relates to how far the piston can be pushed down in turning the crankshaft. It also defines displacement and works like a handle in propelling the crankshaft. The longer the stroke is, the more torque potential there is in an engine design.

If you can collect all the air that passes through all of the cylinders with two complete turns of the crankshaft, the volume of the air then equals the engine’s displacement. So when you stroke the engine by increasing its displacement, you get a larger volume of air/fuel mixture combustion with improved breathing capacity, which results in more power and torque.

What are the Disadvantages of a Stroker Engine?

It would seem to any hot-rodder like you that maximizing both bore and stroke would result in the largest engine and therefore the most power.

On paper, this is true. However, enlarging the bore and lengthening the stroke have some disadvantages as well.

When an engine ignites the air and fuel mixture in the combustion chamber, the flame must travel across the bore to ignite all of the compressed air and fuel in the chamber. Naturally, this takes time to occur.

A large bore requires more time for the burning process to occur, and this will have an impact on the ignition timing.

In fact, research has shown that in most common applications, a bore ceiling of around 4.5 inches is about as large as you should go to maintain a complete burn on pump gas. If the bore is too large, the piston will not have enough time at top dead center to burn the mixture effectively and make the most of its design potential.

Another catch is that if you bore a cylinder block to its limit, you cannot bore it again. Therefore, it is better to save a little room for a rebuild.

The stroke length is also a compromise. Certainly, you are enthusiastic to want the longest stroke possible to maximize displacement, but there are consequences. The longer stroke will deliver increased torque, but the longer throws on the crankshaft and the longer connecting rods or pistons required to work in concert with it all weigh a lot more.

When you are talking about a rotating assembly, weight is your enemy and will restrict the ability of the rotating assembly to spin faster and make more power. These weights all multiply dramatically with RPM, so you must find a happy medium between rotating mass and stroke length.

How Much Horsepower Does a Stroker Add?

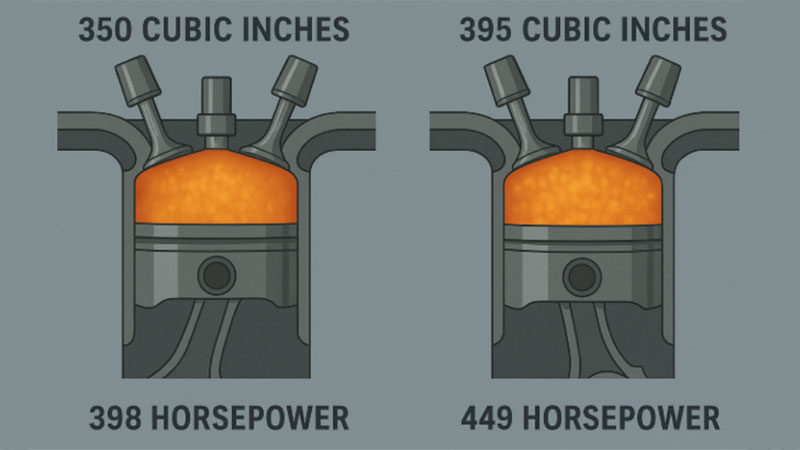

Let’s take an example of the 350 cubic inch and 395 cubic inch engines to calculate approximately how much horsepower they can output after you are done with stroking.

If you have a 350 cubic inches stroker, that means that every time the crankshaft turns twice, the cylinders together move 350 cubic inches of air in and out. The size of the engine directly controls how much air and fuel it can burn, and a larger mixture equals more power potential.

Now compare that to an engine sized at 395 cubic inches. Over those same two turns of the crankshaft, it cycles 395 cubic inches of air. That’s 45 cubic inches more than the 350.

Difference = 395 – 350 = 45 cubic inches

Percent increase = 45 / 350 × 100 = 12.9%

So, a 395 cu in is 12.9% bigger than a 350 cu in.

A bigger engine means more air, more fuel, and more power, and in this case, it is around 12.9% more.

In plain words, if your 350 cubic inch engine made 398 horsepower, then just by boring and stroking it to 395 cubic inch (12.9% more size), you could expect to push out about 449 horsepower.

What are 4 Ways to Stroke an Engine?

There isn’t just one way to stroke an engine to increase displacement. Let’s break them down:

1. Crankshaft Rod Journals Offset Grinding

One option is offset grinding the crankshaft rod journals. Here, material is removed and reshaped so the rod journal sits slightly higher or lower than before. Done correctly, this can add around 0.020 inches of stroke.

2. Swapping In a Larger Crankshaft

Another popular approach is to fit a larger crankshaft into a smaller engine block by machining it to match. For example, a crankshaft from a 360 can be worked into a 318 block, which gives you a bigger engine with more room to move air and fuel.

3. Increasing the Length of the Connecting Rods

You can also lengthen the connecting rods. With longer rods, the pistons travel farther up and down in the cylinder, which directly increases the engine’s stroke and overall displacement.

4. Stroker Kits

For those who want everything ready to go, stroker kits are the simplest route. These kits usually have a new crankshaft, I or H-beam connecting rods, pistons with pins and rings, plus the main and rod bearings. With everything engineered to work together, it saves you the headache of depending on all of the machining and getting it right.

Stroker kits are most often used on naturally aspirated engines, where the only air supply comes from atmospheric pressure instead of a turbo or supercharger.

Conclusion

So, now you know what is a stroker engine, the pros and cons of it, how much more hp you can produce with this approach, and the different ways to do this before you start. The power is the goal here, and if done right, the gains are impressive.

For businesses that want dependable, high-quality products, Nanjing Woda Auto Technology Co., Ltd. stands out as a trusted partner. Since 1999, we have been supplying clients around the world with a complete range of engine components, including ignition systems, electrical parts, exhaust systems, suspension, and steering parts.

Get in touch with us today to build a partnership that delivers mutual growth and strengthens your reputation for offering top-grade auto parts.