Engines aren’t what they used to be. These days, more power, less fuel, and fewer emissions aren’t just wishful thinking—they’re made possible by various advancements within the car industry, and one of the most important ones is Variable Valve Timing (VVT).

This ingenious system fine-tunes your engine in real time, delivering the perfect blend between efficiency and engine performance in all driving conditions. No matter how you use your car, VVT allows you to do it seamlessly.

What is VVT, how does VVT work, and what makes it so essential in modern engines? Stick around, and find out!

What is Variable Valve Timing and How Does VVT Work?

Variable valve timing (VVT) is a clever piece of automotive technology that optimizes engine performance and allows for better fuel efficiency in vehicles. It works by continuously (variably) adjusting the timing of the valves for better fuel economy, emissions, and power output.

VVT is like giving your engine the ability to think. Instead of opening and closing the intake valve and exhaust valves at the same time all the time, VVT adjusts an engine’s timing cycle based on how hard the engine is working, contributing to its improved efficiency.

That means better fuel economy when you’re cruising and more power when you hit the gas — all without you ever lifting a finger. All of this has made Variable Valve Timing one of the greatest inventions of the modern engine, particularly for achieving better fuel consumption.

How the Variable Valve Timing System Works

Now that you are fully aware of what Variable Valve Timing (VVT) is, let’s break down how VVT works!

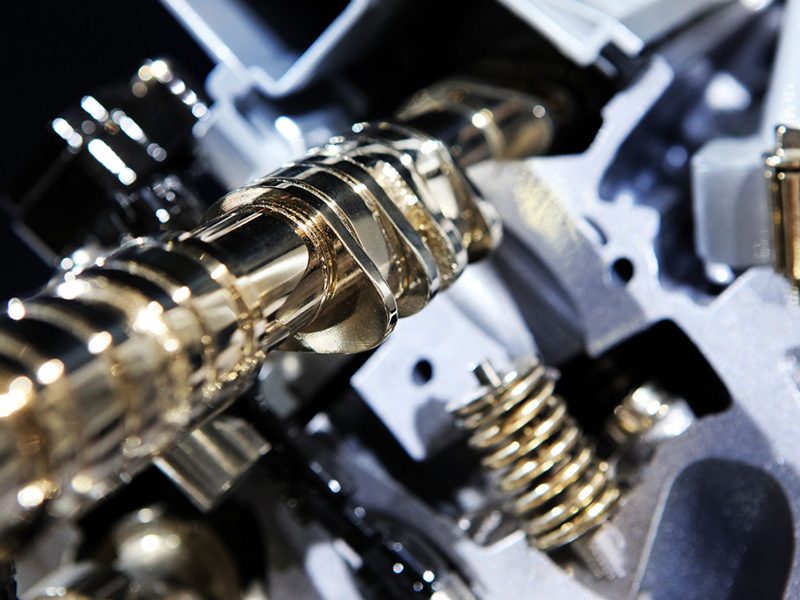

Within a modern variable valve lift timed engine, the timing of the intake valve and the exhaust valve is adjusted using a component called an actuator, also known as the camshaft phaser (cam phaser).

This phaser, typically mounted on the camshaft head, uses good old engine oil pressure to advance or retard the valve timing based on real-time driving conditions and the driver’s inputs.

The entire VVT system is carefully managed and controlled by the engine’s ECU (Electronic Control Unit), which monitors engine speed and throttle load to optimize engine performance, fuel efficiency, and emissions at every step of the way.

Lastly, some VVT setups retain inert gas from the exhaust in the cylinder head to lower combustion temps and reduce NOx emissions.

What are the Key Components of the VVT System?

VVT Cam Phaser

The aforementioned VVT phaser is located directly on the camshaft. It is responsible for adjusting the position of the intake camshaft in perfect relation to the crankshaft.

It controls the valve timing via engine oil pressure, allowing the engine to respond dynamically to changing driving conditions. You can think of the phaser like a conductor, making sure the engine’s parts stay in sync at all times.

Intake Valve Camshaft

The camshaft is tasked with controlling the timely opening and closing of both the exhaust and the intake valve. This is done via camshaft lobes, which are precision-shaped protrusions that push the valves open as they spin.

In a variable valve timing engine, the camshaft works in unison with the phaser to fine-tune valve events operation for engine performance, power, emissions, efficiency, and even comfort.

Oil Control System

The last essential VVT component is the oil pump control system, which regulates oil flow and pressure to the VVT phaser.

Typically managed by an electronically controlled solenoid, the VVT oil precise control system makes sure the timing adjustments happen smoothly and precisely based on input from the ECU, ultimately impacting fuel consumption for the better.

Most Common Types of Variable Valve Timing Systems

There are many variable valve timing engine types out there, and all have their pros and cons, and that’s exactly what we are going to talk about next.

| VVT System | Manufacturer | How It Works |

|---|---|---|

| VVT-i(Basic) | Toyota, GM | Adjusts the intake and exhaust valve closing |

| VTEC | Honda | Switches between two cam profiles |

| Dual VVT-i | Toyota | Adjusts both intake & exhaust timing |

| VANOS | BMW | Uses oil pressure to vary camshaft timing |

| MIVEC | Mitsubishi | Variable valve timing adjusts valve timing & lift |

What’s the Difference Between VVT and VTEC?

In most markets across the globe, VVT and VTEC are compared the most. While both VVT and VTEC improve the performance of an engine, especially at high rpm, the key difference lies in what they primarily control.

On the one hand, VVT adjusts the timing of the valves, while on the other, VTEC changes both the timing and lift of the valves. VVT systems typically prioritize comfort, smoothness, low rpm emissions, and everyday drivability, making them ideal for daily cars and daily commuters.

VTEC is a different breed altogether, as this system shines when high-revving power and aggressive driving are part of the equation.

For many people out there, VTEC is a cult that makes cars more exciting and sportier, while VVT is a piece of technology aimed at making cars more efficient.

Benefits of Variable Valve Timing – VVT vs Dual VVT

To keep it short, there are tons of variable valve timing advantages, and we are going to tell you the most impactful ones of them all.

| Benefit | VVT (Single) | Dual set VVT |

|---|---|---|

| Horsepower | More power at high RPMs by adjusting the intake or exhaust valves. | Provides smoother, more responsive power by adjusting both intake and exhaust independently. |

| MPGs | Pushes efficiency during low-load driving — some gains. | Greater control over combustion = up to 10% better fuel economy. |

| Emissions | Helps reduce emissions - lowers pollutants entering the catalytic converter. | More complete combustion chamber = up to 20% lower emissions. |

| Throttle Response | Obvious improvement in responsiveness. | Sharper, more linear throttle feel due to finer control. |

| Longevity | Reduces stress during high-load or idle conditions. | Optimizes engine dynamics throughout the rev range = more balanced wear. |

| Low RPMs | Intake valve camshaft or exhaust side alone may not be enough for perfect tuning. | Both sides work together = better torque and drivability. |

| Forced Induction | Not always ideal — limited timing flexibility. | Widely used in turbocharger engines for max efficiency & control. |

TL;DR – VVT vs Dual Variable Valve Timing

- VVT is a great all-around solution, ideal for improving daily driving and fuel economy in all driving conditions

- Dual VVT takes things up a notch by independently controlling both valve sets — offering improved performance, cleaner emissions, and superior efficiency across the range.

The Most Common VVT Problems and Error Codes

With such a complex system comes the dreaded reality that VVT can sometimes do more harm than good, especially on older engines. Modern-day internal combustion engines are indeed better, especially at low engine speeds, but sadly, no VVT technology is immune to problems.

The most common VVT system error codes include P0016 and P0017 fault codes, which typically point to troublesome VVT systems. These are likely caused by dirty or low-quality oil, sludge deposits within the engine, or just low oil pressure.

If you encounter these and don’t resolve them, they could very easily lead to cam failures or complete VVT system failure, both of which are serious problems that will require major overhauls.

VVT issues can often produce symptoms that closely resemble symptoms of a faulty crankshaft position sensor, so make sure to keep an eye out for these.

As is obvious, both problems are mostly consequences of poor engine operation and maintenance, which means one can stay ahead of these problems by maintaining the system.

Top 10 Variable Valve Timing (VVT) Maintenance Tips

It’s always better to proactively avoid a VVT problem rather than to fix it, and to do that, make sure you follow these VVT maintenance tips to ensure proper valve lift!

- Regular oil changes — The VVT system relies on clean oil to function properly, so make sure to change your oil regularly.

- Low oil levels can cause grave issues — These include damage to the VVT chain, solenoid, and gear drive, etc

- Avoid/Stop sludge buildup — Dirty oil can clog internal passages and disrupt valve timing, so make sure to keep a lookout.

- Use the correct oil grade and weight — Especially important for CVVT systems controlled by the ECU.

- Don’t ignore codes like P0016 or P0017 — These may indicate VVT system failure, and ignoring them could total your VVT system.

- Proper oil pressure — The system uses oil pressure to advance or retard valve timing, so make sure to keep it in check.

- CVVT systems are electronically controlled — Make sure your ECU is functioning correctly, otherwise it won’t be able to control it.

- Manufacturer-recommended service intervals — Stick to these, especially for oil and filter changes.

- Look for irregular engine noises — Rattling or ticking could point to worn VVT components, so keep a lookout for these as well.

- Get diagnostics done if performance drops — Poor acceleration or fuel economy may sometimes trace back to VVT issues, so diagnose it if you can.

Can I Add VVT to an Engine?

Adding VVT to an engine is indeed possible, but it’s not just a bolt-on upgrade as it requires a VVT timing cover, cam, cam sprocket, VVT timing chain sprocket, and a whole lot of software wizardry.

Camshaft phase limiters are available to safely control the range of camshaft travel, while special camshafts and valve springs are designed to work within the limits of VVT. However, even though technically possible, it’s rarely ever feasible.

Unless you’re building an engine from scratch or have a very specific race application in mind, it’s better to swap in an engine that already has VVT. The fact is that you’ll save money, time, and a boatload of frustration — and you’ll likely get better performance too.

Frequently Asked Questions

What Does VVT Stand For?

VVT stands for Variable Valve Timing, a modern engine technology that adjusts valve opening and closing for better performance and efficiency in all driving conditions.

How Does VVT Improve Fuel Economy?

VVT optimizes intake camshaft valve timing regarding overall engine load and engine speed, improving fuel efficiency, reducing emissions, and enhancing combustion, all of which lowers the total MPG count.

What is the Difference Between VVT and VTEC?

Variable camshaft valve timing adjusts timing continuously, while VTEC (Variable Valve Timing and Lift Electronic Control) switches between two cam profiles depending on whether the driver wants better performance or efficiency.

Can You Upgrade a Non-VVT Engine to VVT?

Although technically possible, it requires a great deal of work, effort, and money: a new ECU, camshafts, camshaft sensors, and extensive software and hardware modification.

What are the Symptoms of a Failing VVT System?

The most common symptoms of a failing variable valve timing system include rough idle, poor fuel economy, check engine light, engine knocking, and engine stalling.

Final Thoughts on Variable Valve Timing

All in all, VVT sure is a game-changer for performance, fuel efficiency, and emissions. It allows you to get the most out of your engine in every driving situation, no matter if you want engine speed or efficiency.

Even though it is an incredibly useful piece of automotive tech, it does require maintenance, which is why you should always keep up with oil changes and maintenance for optimal continuous variable valve timing performance.

Looking to Source Premium OEM and Aftermarket VVT Components for Your Business?

Partner with Nanjing Woda Auto Technology Co., Ltd., a trusted B2B supplier with 25 years of experience in the global automotive parts industry.

Based in Nanjing, China, we offer a full range of engine, ignition, electrical, exhaust, suspension, and steering system parts, providing you with high-quality one-stop procurement solutions and more — all tailored for B2B clients and backed by:

✅ Genuine, tested quality

✅ Competitive B2B pricing

✅ Fast, global logistics

✅ Dedicated customer service & after-sales B2B support

Contact us today to streamline your supply chain and deliver lasting value to your customers!